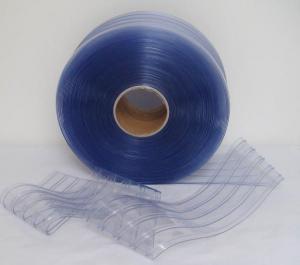

Freezer Grade PVC Strips Rolls Used for Warehouse

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Warehouse use Freezer PVC Strip Curtains

Application tempt range: -40℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

Applications of Warehouse use Freezer PVC Strip Curtains

Polar PVC strip curtain remain highly soft even at 40 Celsius below zero, allowing easy passing of people, vehicles and goods and effectively preventing loss of cold air. Polar PVC sheet is a good choice for save power because they do not contain electric drive. Polar door curtain do not have action component and do not produce noise during service. Cool strip has been designed from market experience and has been proved in independent tests to up to 50% of energy costs, while helping retail chill cabinets meet statutory temperature controls.

Polar grade PVC strip curtains are an option for Cold storage, Refrigerated doorways, Deli-Counters, Chiller Cabinets, Cold rooms and most retail refrigeration situations.

Package& Delivery of Warehouse use Freezer PVC Strip Curtains

Wooden pallet,shirnk film,cartons and according to custom requires.

Colors of Warehouse use Freezer PVC Strip Curtains

Polar door curtain are available in a range of colors, such like pale green, pale blue and clear. Blue is the most popular color in usages. If you used in the dark environment, just like cold rooms, clear color is the best choice for you.

Styles of Warehouse use Freezer PVC Strip Curtains

There are three styles of PVC strip curtain, Smooth, Single Ribbed and Double Ribbed. The door curtain used is dependent on the applications. PVC strips with raised ribbing on both sides are available offering improved durability enabling them to withstand repeated impact from heavy traffic such as forklift trucks.

- Q: Can plastic components in home appliances be recycled with regular household recycling?

- Yes, plastic components in home appliances can often be recycled with regular household recycling. However, it's important to check with your local recycling guidelines to ensure they accept these types of items. Some appliances may need to be taken to specific recycling centers or facilities to ensure proper recycling and disposal.

- Q: Can plastic parts in home appliances be easily cleaned with specialized cleaning solutions?

- Yes, plastic parts in home appliances can generally be easily cleaned with specialized cleaning solutions. These solutions are designed to effectively remove dirt, grime, and stains without causing damage to the plastic surfaces. However, it is important to carefully read the instructions and ensure that the cleaning solution is suitable for the specific type of plastic used in the appliance.

- Q: Are there any specific guidelines for handling or storing plastic parts during transportation?

- Yes, there are specific guidelines for handling and storing plastic parts during transportation. It is recommended to avoid excessive stacking, which can cause deformation or breakage. Plastic parts should be stored in a clean and dry environment, away from direct sunlight and extreme temperatures. Additionally, using protective packaging or padding can help prevent scratching or damage during transit.

- Q: What are the typical lifespan expectations for home appliance plastics?

- The typical lifespan expectations for home appliance plastics can vary depending on factors such as the quality of the plastic, the specific appliance, and how well it is maintained. However, on average, home appliance plastics are designed to last for several years, ranging from 5 to 15 years.

- Q: Are there any concerns with using plastic in appliances that generate electromagnetic interference?

- Yes, there are concerns with using plastic in appliances that generate electromagnetic interference. Plastic is a non-conductive material, which means it can potentially interfere with the proper functioning of electromagnetic shielding and containment. This interference can result in increased levels of electromagnetic radiation, potentially causing interference with other electronic devices and even posing health risks to humans. Therefore, it is crucial to carefully design and engineer appliances with plastic components to minimize electromagnetic interference and ensure compliance with safety standards.

- Q: Can plastic parts in washing machines handle the constant friction and movement during the spin cycle?

- Yes, plastic parts in washing machines are designed to handle the constant friction and movement during the spin cycle. Manufacturers use high-quality, durable plastics that are specifically engineered to withstand the stress and impact of the spinning motion. These plastic components are rigorously tested to ensure they can withstand the demands of regular use and maintain their integrity over time.

- Q: Can plastic parts in home appliances be affected by exposure to chemicals in household cleaning products?

- Yes, plastic parts in home appliances can be affected by exposure to chemicals in household cleaning products. These chemicals can cause the plastic to deteriorate, discolor, or become brittle over time. It is important to read and follow the manufacturer's instructions for cleaning and avoid using harsh chemicals that may damage the plastic components.

- Q: Are there any specific guidelines for recycling or upcycling plastic parts from old home appliances?

- Yes, there are specific guidelines for recycling or upcycling plastic parts from old home appliances. It is recommended to first check with your local recycling facilities or waste management authorities for specific instructions on how to properly recycle or dispose of plastic parts. Additionally, upcycling plastic parts can be a creative way to give them a new purpose, and there are various online resources and DIY guides available that provide guidelines and ideas for upcycling plastic components from old appliances.

- Q: Can plastic parts in home appliances be affected by exposure to strong magnetic fields?

- Yes, plastic parts in home appliances can be affected by exposure to strong magnetic fields. The magnetic fields can induce currents in the plastic, leading to heating and potential degradation of the material. This can result in the distortion or failure of the plastic parts, impacting the overall functionality of the appliances.

- Q: Can plastic parts in home appliances be easily disassembled for maintenance or repairs?

- No, plastic parts in home appliances are typically not easily disassembled for maintenance or repairs.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1991 |

| Annual Output Value | US$ 1 Million - US$ 2.5 Million |

| Main Markets | 40.00% Southeast Asia 15.00% Mid East 10.00% South America 5.00% Southern Europe 5.00% Northern Europe 5.00% Western Europe 5.00% Oceania 5.00% Africa 5.00% Eastern Europe 5.00% North America |

| Company Certifications | ISO 9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Freezer Grade PVC Strips Rolls Used for Warehouse

- Loading Port:

- Tianjin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords