PVC High Polymer Waterproofing Membrane for Construction Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of PVC membrane:

|

20m/roll or customized |

Width | 2.05m |

Thickness | 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm or customized |

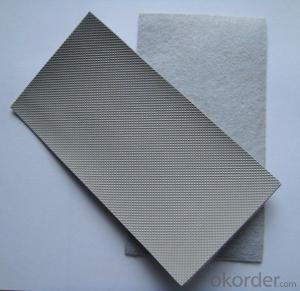

Type | Polyester scrim reinforced PVC waterproofing membrane |

If Exposed | Exposed and Non-exposed |

Color | All accepted |

Composition:

The P series waterproofing membrane is a high-quality,thermoplastic PVC membrane with a polyester scrim reinforcement. We solved the problem of extraction and migration of PVC plasticizer in production, make the products the best durability in thermoplastic waterproofing.

Features and Benefits:

l High Strength

l Hot-air welded seams for long-term performance

l Proven membrane performance

l Excellent resistance to plasticizer extraction and migration performance.

Packaging:

The rolls of P series waterproofing membrane are wrapped in a protective film and strapped to a wood pallet. The P series waterproofing membrane lengths of 15m, 20m, 25m, widths of 1.03m, 2.05m and thicknesses of 1.20mm, 1.50mm, 1.80mm, 2.00mm or customized according to customers requirements.

Installation:

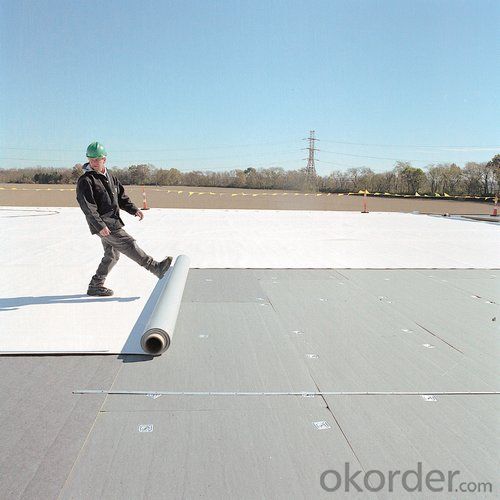

The P series waterproofing membrane is installed by a Magical Stone Authorized Applicator.

P series is rolled out onto the insulation board or acceptable substrate,fastened to the surface and heat-welded together by trained operators using Magical Stone's hot-air welding equipment.

Availability:

The P series waterproofing membrane is available directly from Magical Stone Autherized Applicators. Contact your Magical Stone Regional Office or visit our website for further information.

Warranty:

Upon successful completion of the installed surface by the Magical Stone Authorized Applicator, Magical Stone can provide a Warranty to the Building Owner via the Authorized Applicator.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be installed over existing coatings or sealants?

- Yes, a waterproofing membrane can be installed over existing coatings or sealants, depending on the condition of the existing surface. However, it is important to ensure that the surface is clean, dry, and free from any loose or damaged material before installing the membrane. Proper surface preparation is crucial to ensure the new membrane adheres well and provides effective waterproofing. It is also recommended to consult with a professional to determine the compatibility of the existing coatings or sealants with the waterproofing membrane to avoid any potential issues or failure of the system.

- Q: Can a waterproofing membrane be used for laboratories or research centers?

- Laboratories or research centers can benefit greatly from utilizing a waterproofing membrane. These membranes are specifically designed to create a barrier against water and moisture, effectively preventing any infiltration that could potentially damage the structure. Given the presence of sensitive equipment, valuable specimens, and crucial data in these environments, it becomes imperative to uphold a controlled atmosphere that is completely free from any moisture. To ensure that water leaks do not occur, a waterproofing membrane can be applied to various surfaces, including floors, walls, and roofs. This application serves to safeguard the equipment, ward off potential hazards, and preserve a safe working environment. Moreover, the presence of a waterproofing membrane aids in the prevention of mold growth, which is vital for maintaining optimal air quality within laboratories and research centers. Ultimately, opting for a waterproofing membrane is a wise decision that guarantees the integrity and functionality of laboratories and research centers.

- Q: Are waterproofing membranes resistant to earthquake-induced water pressure?

- Yes, waterproofing membranes are designed to be resistant to earthquake-induced water pressure. These membranes are specifically engineered to provide a barrier against water infiltration, even under high-pressure situations caused by an earthquake.

- Q: What type of maintenance is required for a waterproofing membrane?

- Regular maintenance is required for a waterproofing membrane to ensure its effectiveness and longevity. This maintenance typically includes inspecting the membrane for any signs of damage, such as cracks or tears, and promptly repairing them. Additionally, it is important to keep the membrane clean and free from debris to prevent clogging or blockages. Regular inspections and maintenance will help to extend the life of the waterproofing membrane and ensure it continues to effectively protect the underlying structure.

- Q: Can a waterproofing membrane be used for tunnels?

- Yes, a waterproofing membrane can be used for tunnels. Tunnels are often exposed to water infiltration due to their underground nature, making waterproofing crucial to prevent water damage and ensure structural integrity. Waterproofing membranes, which are specially designed to provide a barrier against water penetration, can be applied to the tunnel walls, floors, and ceilings to create a waterproof seal. These membranes are typically made of materials such as bitumen, EPDM, PVC, or polyurethane, which are highly resistant to water and can withstand the constant exposure to moisture in tunnels. Additionally, waterproofing membranes can also provide protection against other potential sources of water ingress, such as groundwater or heavy rainfall. Overall, the use of a waterproofing membrane in tunnels is a reliable and effective method to maintain a dry and safe environment within the tunnel structure.

- Q: Can a waterproofing membrane be used in areas with chemical exposure?

- In areas where there is chemical exposure, it is possible to use a waterproofing membrane. However, it is vital to choose a waterproofing membrane that is specifically created to withstand chemical exposure. Not all waterproofing membranes are equal, and some may not be suitable for use in areas with chemical exposure. Waterproofing membranes that are resistant to chemicals are typically made from materials like polyurethane, epoxy, or polyurea, which are known for their ability to withstand various chemicals. These membranes are designed to act as a protective barrier against moisture and chemicals, preventing them from penetrating the underlying surfaces. When selecting a waterproofing membrane for areas with chemical exposure, it is crucial to consider the particular chemicals that will be present. Different chemicals can have varying effects on materials, so it is essential to choose a membrane that is specifically designed to resist the chemicals in the environment. It is recommended to consult with a professional or the manufacturer to ensure the appropriate selection of a chemical-resistant waterproofing membrane for the specific application.

- Q: Can a waterproofing membrane be used in bathrooms or showers?

- Yes, a waterproofing membrane can be used in bathrooms or showers. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water damage and leakage. A waterproofing membrane acts as a barrier that prevents water from penetrating through the walls, floors, and other surfaces in the bathroom or shower. It is typically applied before tiling or finishing the surfaces, providing an extra layer of protection against moisture and ensuring that the underlying structure remains dry. This not only helps to prevent mold and mildew growth but also prolongs the lifespan of the bathroom or shower.

- Q: Can a waterproofing membrane be used on galvanized surfaces?

- Yes, a waterproofing membrane can be used on galvanized surfaces. Galvanized surfaces are typically used to protect metal from corrosion, and applying a waterproofing membrane can further enhance the protective properties of the galvanized coating. The membrane can provide an additional layer of defense against water penetration, preventing moisture from reaching the galvanized surface and potentially causing rust or other damage. However, it is important to ensure that the waterproofing membrane is compatible with the galvanized surface and is specifically designed for use in such applications. It is also recommended to consult with the manufacturer or a professional to ensure proper installation and compatibility before applying a waterproofing membrane on galvanized surfaces.

- Q: Can a waterproofing membrane be used for plant rooms or mechanical spaces?

- Plant rooms or mechanical spaces can benefit from the use of a waterproofing membrane. These areas house various equipment, machinery, and systems, often containing pipes, tanks, and other components that require protection from water damage. A waterproofing membrane serves as a strong and flexible barrier that effectively prevents water infiltration. It can be applied to walls, floors, or ceilings, ensuring the longevity and functionality of the equipment and systems by safeguarding them against water leaks or moisture damage. Furthermore, the application of a waterproofing membrane also serves as a vapor barrier, preventing the accumulation of condensation or humidity that can adversely affect sensitive equipment.

- Q: Can a waterproofing membrane be used for a fountain?

- Yes, a waterproofing membrane can be used for a fountain. Waterproofing membranes are designed to create a protective barrier against water, making them suitable for fountains to prevent leakage and maintain the structural integrity of the fountain.

Send your message to us

PVC High Polymer Waterproofing Membrane for Construction Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords