PVC Waterproofing Membrane Reinforced with Fiberglass

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproofing Membrane Reinforced with Fiberglass

Product Description of PVC Waterproofing Membrane Reinforced with Fiberglass:

PVC waterproofing membrane is an excellent high-quality polymer waterproof sheet, made of PVC resin by adding plasticizer, anti-UV agent, anti aging agent, and stabilizer and other processing aids through extrusion and molding. As the highly recommended product by the Ministry of Construction, it is featured by high tensile strength, great elongation, good stability, small shrinkage, low-temperature performances, good resistance to weathering and root

penetration, and long service life.

Features of PVC Waterproofing Membrane Reinforced with Fiberglass:

1.Long service life and weathering resistance; and the materials can be used for 30 years on the roof and 50 years underground.

2. High tensile strength, great elongation, and small size change during heat treatment.

3. Good low temperature flexibility and adaptability to environmental temperature changes.

4. Good resistance to root penetration. It can be made for green roofs.

5. Excellent resistance to puncture and impact.

6. Convenient for construction (can be welded), solid and reliable, and Eco-friendly.

7. Strong resistance to chemical corrosion, suitable for special occasions.

8. Good plasticity, convenient and quick corner detail treatment. Easy maintenance and low cost.

9.After 2,000 hours of manual weathering verification

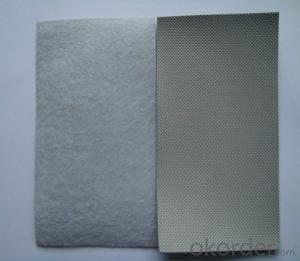

Classification of PVC Waterproofing Membrane Reinforced with Fiberglass:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproofing Membrane Reinforced with Fiberglass:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproofing Membrane Reinforced with Fiberglass:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproofing Membrane Reinforced with Fiberglass:

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

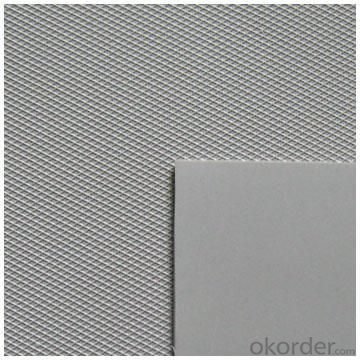

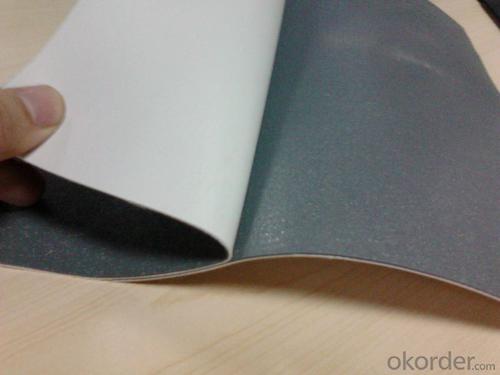

Images of PVC Waterproofing Membrane Reinforced with Fiberglass:

FAQ of PVC Waterproofing Membrane Reinforced with Fiberglass:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used for sewage treatment plants and wastewater facilities?

- Yes, a waterproofing membrane can be used for sewage treatment plants and wastewater facilities. These membranes are designed to prevent water penetration and are commonly used to protect structures from water damage. In sewage treatment plants and wastewater facilities, where constant exposure to water and moisture is present, a waterproofing membrane can help maintain the integrity of the structures and prevent any leaks or water seepage.

- Q: Can waterproofing membranes be used on green roofs?

- Indeed, green roofs can utilize waterproofing membranes. They serve as an indispensable element within green roof systems. The concept of green roofs involves a layer of plants and growing medium situated atop a waterproofing layer. It is this waterproofing layer that safeguards the building structure by preventing water infiltration and subsequent damage. The waterproofing membranes employed in green roof applications are specifically engineered to withstand the unique challenges posed by such installations, including exposure to water, UV radiation, and root penetration. These membranes are typically composed of durable materials such as PVC, TPO, or EPDM, renowned for their exceptional waterproofing capabilities. Moreover, certain waterproofing membranes used on green roofs may possess additional attributes like root resistance and UV stability, thereby ensuring the roof's longevity and imperviousness. Ultimately, the utilization of waterproofing membranes on green roofs plays a vital role in establishing a sustainable and enduring roofing system that not only provides water protection but also offers environmental advantages.

- Q: Can a waterproofing membrane be used on concrete block surfaces?

- Yes, a waterproofing membrane can be used on concrete block surfaces. It is commonly used to prevent water penetration and protect the underlying structure from moisture damage.

- Q: Does a waterproofing membrane prevent mold and mildew growth?

- Indeed, the growth of mold and mildew can be prevented with the aid of a waterproofing membrane. These fungi flourish in environments characterized by dampness and moisture, but a waterproofing membrane acts as a barrier, thwarting the infiltration of water into the treated surfaces. By keeping moisture at bay, it diminishes the circumstances that facilitate the proliferation of mold and mildew. Nonetheless, it is crucial to acknowledge that while a waterproofing membrane is effective in preventing such growth, it does not ensure absolute protection. Adequate ventilation and consistent upkeep are also imperative in the battle against mold and mildew.

- Q: How does a waterproofing membrane handle movement joints or cracks?

- A waterproofing membrane is designed to handle movement joints or cracks by providing a flexible and stretchable barrier that can accommodate the shifting or settling of a structure. When there are movement joints or cracks present, the membrane is applied in a way that creates a continuous and seamless layer over the surface. The flexibility of the waterproofing membrane allows it to move and adapt to changes in the structure, such as expansion or contraction, without compromising its integrity. This is especially important in areas where there is significant movement or where cracks are prone to develop, such as in concrete slabs or foundations. In the case of movement joints, the membrane is typically terminated or split at the joint to allow for movement without creating stress or tension on the membrane. This ensures that any movement or shifting of the structure does not cause the membrane to tear or fail. For cracks, the waterproofing membrane is applied directly over the surface, bridging the gap and sealing it off from water infiltration. The flexible nature of the membrane allows it to stretch and conform to the shape of the crack, effectively sealing it and preventing further water damage. Overall, a waterproofing membrane is designed to handle movement joints or cracks by providing a durable and flexible barrier that can accommodate structural movements and prevent water penetration. This helps to maintain the integrity of the structure and protect it from water damage.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oils?

- Yes, a waterproofing membrane is generally resistant to hydrocarbons or oils. The materials used in waterproofing membranes, such as bitumen or synthetic polymers, are typically designed to have high resistance to various chemicals, including hydrocarbons and oils. This resistance helps to ensure that the membrane remains effective in preventing water penetration even in the presence of these substances. However, it is important to note that the specific resistance level may vary depending on the type and quality of the waterproofing membrane. It is always recommended to consult the manufacturer or supplier to determine the exact resistance capabilities of a specific waterproofing membrane.

- Q: Can a waterproofing membrane be used in balconies or decks?

- Waterproofing membranes can be utilized in balconies or decks to prevent water penetration and safeguard underlying structures against moisture damage. Balconies and decks are frequently exposed to various weather conditions, including rain and snow, which can result in water damage and deterioration. By installing a waterproofing membrane, a barrier is established that hinders water from seeping into the underlying structure, ensuring its long-lasting and sturdy nature. Moreover, waterproofing membranes also provide protection against other forms of water damage, such as the growth of mold and mildew, which can compromise the integrity of the balcony or deck. In summary, the use of a waterproofing membrane is an efficient solution to maintain the functionality and prolong the lifespan of balconies or decks.

- Q: How is a waterproofing membrane installed?

- A waterproofing membrane is typically installed by first preparing the surface, such as cleaning and removing any debris. Then, a primer or adhesive is applied to the surface to ensure proper adhesion. The membrane is then rolled or laid out onto the surface, ensuring it is properly aligned and overlapping seams to prevent any potential leaks. The membrane is then pressed down firmly to remove any air bubbles and ensure a secure bond. Any additional layers or coatings may be applied as necessary.

- Q: Can a waterproofing membrane be used for wastewater facilities?

- Yes, a waterproofing membrane can be used for wastewater facilities. Waterproofing membranes are commonly used in wastewater facilities to prevent water leakage and seepage. They provide an effective barrier against water infiltration and protect the structure from water damage. Additionally, these membranes are resistant to chemicals and can withstand harsh environmental conditions often found in wastewater facilities.

- Q: Can waterproofing membranes be applied on roofs?

- Roofs can have waterproofing membranes applied to them, a practice commonly employed in the construction industry to add an extra layer of protection against water infiltration. These membranes, typically composed of synthetic materials like PVC, TPO, or EPDM, possess high resistance to water and effectively prevent leaks and water damage on roofs. Applying waterproofing membranes on roofs is a proven method for enhancing the longevity and durability of the roofing system, particularly in areas prone to heavy rainfall or extreme weather conditions. Moreover, waterproofing membranes are flexible and can be easily installed on various roofing materials such as concrete, metal, or asphalt shingles. Consequently, if you desire a watertight roof and wish to safeguard your property from water-related problems, the utilization of waterproofing membranes offers a dependable and efficient solution.

Send your message to us

PVC Waterproofing Membrane Reinforced with Fiberglass

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords