C10 PVDF-PE Prepainted Aluminum Coil with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Aluminium Coil with PVDF Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the AA5052 Aluminium Wire:

Wood grain-coated aluminum sheet with PVDF and can be used for many fields such as roofing, ceiling, curtain wall, lamp decoration, aluminum composite panel, honeycomb plate, doors and furniture.

Adapts aluminum coil and use best imported paint, composition contains 70% PVDF.

Technology is four coating and two baking.

Surface of products is smooth and dry.

Color is uniform.

Resist UV in air and corrosion.

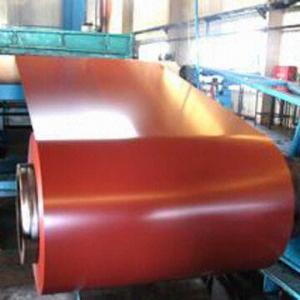

Images of Prepainted Aluminium Coil with PVDF:

Prepainted Aluminium Coil with PVDF Specification:

| product | alloy | temper | size (mm) | ||

| thinckness | width | ||||

| aluminum coil/Color coated al coil/sheet with PE or Pvdf | 1070 1060 1050 1145 1235 1035 1100 1200 3A21 3003 3103 8011 | H18 H14 H16 H22 H24 0 | 1.0-4.0 | 60-1500 | |

FAQ of Prepainted Aluminium Coil with PVDF:

a) What's your process of this type aluminium?

Decoiler → Accumulator→Tension Leveller →Acid&Alkali Cleaner → Rinse →Conversion Treatment → Priming coater →Infrared Curing Oven →Main coater →Floatation Curing Oven →Strippable Film Applicator → Exit Accumulator →Recoiler

b)Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: How do aluminum sheets perform in terms of heat reflectivity?

- Aluminum sheets are highly efficient in terms of heat reflectivity. Due to their high reflectivity, they are able to effectively reflect heat and light away from the surface, thereby minimizing heat absorption. This property makes aluminum sheets an ideal choice for applications where heat management is crucial, such as in roofing, insulation, and solar panels. The reflective nature of aluminum sheets helps to reduce energy consumption by preventing excessive heat buildup, resulting in a cooler environment. Additionally, aluminum's reflectivity also contributes to its use in various industrial and scientific applications, such as in the manufacturing of reflectors, heat sinks, and optical mirrors.

- Q: we have the mass of an aluminum sample =.47g, and the number of atoms in sample =107

- Look up the atomic mass of aluminum on your periodic table, multiply by 107, then divide by .47g?

- Q: How are aluminum sheets different from aluminum plate?

- Aluminum sheets and aluminum plates are two forms of aluminum metal that differ primarily in terms of thickness. Aluminum sheets are typically thin, flat pieces of aluminum that are less than 6mm thick. They are commonly used in applications where lightweight and flexibility are important, such as in the construction of aircrafts, automobiles, and electronic devices. On the other hand, aluminum plates are thicker and heavier than sheets, typically measuring 6mm or more in thickness. Plates are often used in applications that require strength and durability, such as in the construction of heavy machinery, structural supports, and marine equipment. While both sheets and plates are made from aluminum, their distinct thicknesses make them suitable for different purposes.

- Q: This question asks for methods to clean aluminum sheets to preserve their appearance.

- <p>To clean aluminum sheets and maintain their appearance, follow these steps: 1. Use a mild detergent mixed with warm water to create a cleaning solution. 2. Gently scrub the aluminum sheets with a soft cloth or sponge to avoid scratching the surface. 3. Rinse thoroughly with clean water to remove any detergent residue. 4. Dry the sheets immediately with a soft, dry cloth to prevent water spots. 5. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. 6. Avoid using harsh chemicals or abrasive materials that can damage the aluminum's finish. Regular cleaning will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: Can aluminum sheet be bent or formed into different shapes?

- Yes, aluminum sheet can be easily bent or formed into different shapes. Aluminum is a highly malleable metal, which means it can be easily bent, shaped, or formed without cracking or breaking. This property makes it an ideal choice for various applications where flexibility and customization are required. Aluminum sheets can be bent using various methods, such as using a brake press, roll forming, or by hand using specialized bending tools. The level of bendability may vary depending on the thickness and grade of the aluminum sheet, but in general, aluminum is known for its excellent formability and ability to be shaped into different configurations.

- Q: How much is a square inch of a millimeter aluminum plate?

- Make a supplement to the answer on the first floorSo-called:1 lines, when referring to pure aluminum, that is, aluminum content is not less than 99%., weight 2.71 kg / square meterThe 3 Series refers to manganese as the main alloying element, that is, aluminum manganese alloy.

- Q: Are aluminum sheets suitable for signage applications?

- Yes, aluminum sheets are highly suitable for signage applications due to their durability, lightweight nature, and ability to withstand various weather conditions. They are also easy to customize, making them a popular choice for both indoor and outdoor signage.

- Q: I saw a guy on ebay take a washed out paint can fill it full of lighted charcoal bricks and a tin can in the middle. He was melting aluminum cans in there then pured it into a mold. Does this really work and does anyone have any good ideas on how else to do this?

- Aluminum alloys melt at around 1200 degrees, aluminum cans maybe somewhat lower, but I doubt a tin can would hold up long enough to melt much aluminum, and you would need to be very careful, any moisture in your mold will cause the aluminum to literally explode back into your face. I am not saying it couldn't be done, but you really would need lots of safety equipment before trying it.

- Q: Over the years, the thermite reaction has been used for welding railroad rails, in incendiary bombs, and to ignite solid-fuel rocket motors. The reaction is given below.Fe2O3(s) + 2 Al(s) 2 Fe(l) + Al2O3(s)What masses of iron(III) oxide and aluminum must be used to produce 10.0 g iron?a) iron (III) oxideb)aluminiumc)What is the maximum mass of aluminum oxide that could be produced?

- i'm uncertain regardless of the incontrovertible fact that it must be relaxing, are you making thermite? i might guess which you would be able to artwork this out from the atomic weights of each, and taking the valencies under consideration - 2 aluminium atoms for 3 oxygen atoms. 2 iron atoms for 2 oxygen (a million:a million).

- Q: How does aluminum sheet perform in extreme temperatures?

- Aluminum sheet performs well in extreme temperatures as it has a high melting point of 660°C (1220°F) and exhibits excellent thermal conductivity. It can withstand both hot and cold temperatures without significant deformation or structural damage, making it suitable for various applications in extreme environments.

Send your message to us

C10 PVDF-PE Prepainted Aluminum Coil with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords