Coiled Aluminum Prepainted Coil with PVDF/PE 1xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminium Prepainted Coil with PVDF/PE 1XXX:

Aluminium Prepainted Coil with PVDF/PE 1XXX are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Prepainted Coil with PVDF/PE 1XXX:

High intensity.

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance.

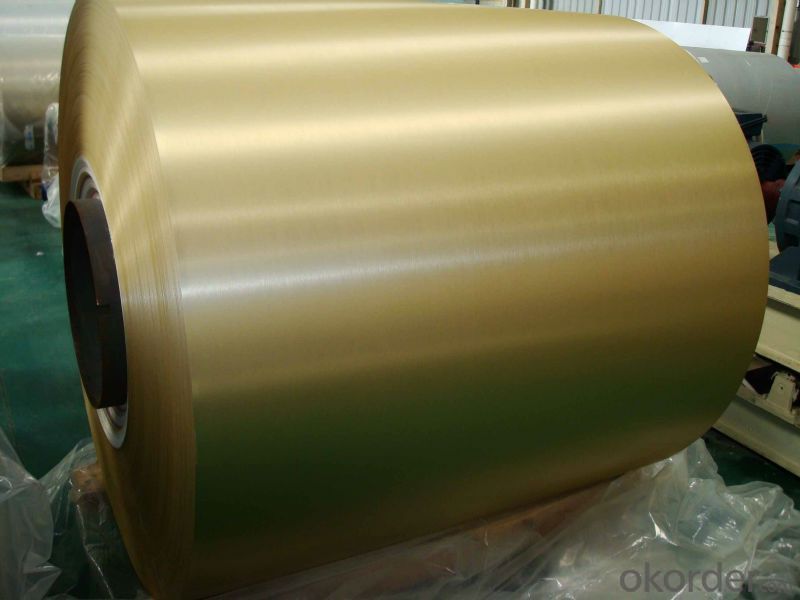

Images of Aluminium Prepainted Coil with PVDF/PE 1XXX:

Aluminium Prepainted Coil with PVDF/PE 1XXX Specifications:

| Alloy | 1050 1060 1100 3003 3004 3005 3014 3105 3A21 5A02 5005 5052 5083 5251 6061 6063 etc |

| Temper | F O H12 H22 H14 H24 H16 H26 H18 H32 H34 H38 H111 H1112 H116 H321 T5 T6 etc |

| Thickness | 0.02mm - 1.2mm |

| Width | Standard width: 1200mm 1240mm ; Special width:1300mm 1520mm 1570mm 1595mm |

| Diameter | Standar dia: 1200mm ; Interior dia: 150mm 405mm 505mm |

| Weight | 1 T / coil -- 3 T / coil |

| Coating | PE PVDF ACRYLIC |

| Surface | Coated , Mill Finish ,Embossed |

| Color | Ral Color |

| Gloss | 10-90%(EN ISO-2813:1994) |

| Coating Thickness | PE: more than 18 micron PVDF : more than 25 micron |

Coating Hardness (pencilresistance) | More than 2 h |

| Coating Adhesion | 5J (EN ISO - 2409 : 1994 ) |

| Impact Resistance | No peeling or cracking (50kg / cm ,ASTMD - 2794 : 1993 ) |

| Flexibility(T-bend) | 2 T |

| MEK resistance | More than 100 |

| MOQ | 2 T |

| Payment Terms | TT or LC at sight |

| Applycation | Mainly in construction, decoration ,PCB materials, labels, house hold appliance ,lift, cover material ,LCD back panel, refrigeration, air conditioner ,automobile etc |

FAQ:

a: Where is your factory:

Henan Provence.

b:Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: Why is the aluminum roll upset?

- Mainly in the aluminum slitting process, for various reasons, does not meet the standards and specifications of products, can be used to roll the machine from the new trimming and slitting, winding up to meet customer needs of product specifications

- Q: How much is a ton gate of Jiangxi aluminium roll?

- Hello, roll gate is usually calculated according to the square count. Is there your Lian Xi?Want to know the size of your installation? The following guidelines and measurement for your reference, you can go out according to the guidelines for measuring hole length and width, a specific size can determine the lattice dielectric.

- Q: What are the potential applications of coil-annealed aluminum coils?

- Coil-annealed aluminum coils have a wide range of potential applications in various industries. One potential application is in the automotive industry. Coil-annealed aluminum coils can be used to manufacture lightweight parts and components for vehicles. The lightweight nature of aluminum makes it an ideal material for improving fuel efficiency and reducing emissions. These coils can be used to produce body panels, chassis components, and structural parts in automobiles. Another potential application is in the construction industry. Coil-annealed aluminum coils can be used to manufacture roofing, siding, and wall cladding materials. The corrosion-resistant properties of aluminum make it a suitable choice for outdoor applications where durability is important. Additionally, the lightweight nature of aluminum makes it easier to handle and install, reducing labor and transportation costs. Coil-annealed aluminum coils can also find applications in the packaging industry. Aluminum is a great choice for food and beverage packaging due to its non-toxic, odorless, and impermeable qualities. These coils can be used to produce cans, foil wraps, and pouches, providing a safe and hygienic packaging solution. Furthermore, coil-annealed aluminum coils can be used in the electrical and electronics industry. Aluminum has excellent electrical conductivity, making it suitable for power transmission lines, electrical components, and heat sinks for electronic devices. Its lightweight nature also makes it easier to handle and install in various electrical applications. Overall, the potential applications of coil-annealed aluminum coils are diverse and span across several industries. From automotive to construction, packaging to electrical, the versatility, durability, and lightweight properties of aluminum make it an excellent choice for various manufacturing needs.

- Q: Can aluminum coils be used in the manufacturing of electronic devices?

- Yes, aluminum coils can be used in the manufacturing of electronic devices. Aluminum is a versatile and widely-used material in various industries, including electronics. Aluminum coils are often used in the construction of transformers, inductors, and other components of electronic devices. One of the main advantages of using aluminum coils in electronic devices is their lightweight nature. Aluminum is much lighter than other commonly used materials like copper, which makes it easier to handle and transport. Additionally, aluminum has good thermal conductivity, allowing for efficient heat dissipation within electronic devices. Furthermore, aluminum coils are resistant to corrosion, which is crucial in electronic applications where the devices may be exposed to moisture or other harsh environments. This corrosion resistance helps to prolong the lifespan of the electronic device and ensures its reliability. Moreover, aluminum coils can be easily formed into various shapes and sizes, making them suitable for different electronic device designs. They can be customized to meet specific requirements, such as fitting into compact spaces or achieving specific electrical characteristics. Overall, aluminum coils offer several advantages in the manufacturing of electronic devices, including their lightweight nature, good thermal conductivity, corrosion resistance, and flexibility in design.

- Q: How are aluminum coils coated to enhance their durability?

- Aluminum coils are coated through a process called coil coating, where a thin layer of protective material is applied to enhance their durability. This coating can be done through various methods such as roll coating, spray coating, or coil coating lines. The coating material used is typically a combination of resins, polymers, and additives, which provide resistance against corrosion, UV rays, abrasion, and other environmental factors. This coating process helps to extend the lifespan of aluminum coils and maintain their appearance and performance even in harsh conditions.

- Q: Are aluminum coils suitable for food storage containers?

- Yes, aluminum coils are suitable for food storage containers. Aluminum is a popular material choice for food storage containers due to its various advantageous properties. Firstly, aluminum is lightweight, making it easy to handle and transport. Additionally, aluminum has excellent thermal conductivity, which means it can cool down or heat up quickly, making it ideal for both hot and cold food storage. Moreover, aluminum is resistant to corrosion and does not react with acidic or alkaline foods, ensuring that the taste and quality of the food remain intact. Furthermore, aluminum is a sustainable and recyclable material, making it environmentally friendly. However, it is important to note that aluminum containers should be lined with a food-grade coating to prevent any potential reaction between the metal and the food, especially acidic foods. Overall, aluminum coils are a suitable choice for food storage containers due to their lightweight nature, thermal conductivity, corrosion resistance, and recyclability.

- Q: if the resistivity of aluminium is 2.7×10-8 Ωm

- Let ρ be the resistivity of the aluminum cable, A the cross sectional area of the cable and l the cable's length. The resistance R of the aluminum cable is now given by: R = ρ·l / A = 2.7·10^-8·(10·10^3) / (π·r?) = 2.7·10^-8·(10·10^3) / (π·(1·10^-3)?) = 85.9 Ω I guess the tricky part is remembering: R = ρ·l / A but when you realize how intuitive this equation is you don't have to memorize it. The resistance R is proportional to the resistivity ρ, so we must have the following in our equation: R = ρ·k , where k is some value governed by the dimensions of the cable! It is logical that the resistance is also proportional to the wires length l. This is logical when you realize that the longer the wire the more obstacles the electrons will have to pass by! Now we have that: R = ρ·l·c , where c is another value governed now by the cross sectional area (only dimensional property left). If we think of the wire as a highway with cars instead of electrons we realize that there is less resistance (higher speed) when the highway has many lanes and is very broad. From this we realize that the greater the cross sectional area the smaller the resistance. R must therefore be inversely proportional to A. We now have: R = ρ·l / A I hope there are no mistakes here :P

- Q: Im doing an assignment for science and i need to know the nuclear charge of Aluminium?and also is there a difference between Aluminium and Aluminum or can it just be spelt differently?

- Aluminum by itself has no charge it is neutral. The number of electrons matches the number of protons. The electrons on aluminum move with ease, that is why it is used as a wire. If one of the electrons is lost it becomes a positive ion with a charge of +1. If the Aluminum has one more electron than protons then it is said to be a negative ion with a charge of -1. Gravity is the summation of all the attractive and repulsive forces in the location being considered. Gravity is when the attractive forces are stronger. Neutral gravity is when the attractive and repulsive forces match exactly. (very rare) Anti-Gravity is when the repulsive forces are stronger. Anti-gravity is quite common and is one of the primary causes for star formation in galaxies. Stars are actually secondary to the process. The Primary process is a quasar of mostly protons emerging like a bubble from a galactic core after splitting off from its neutrons deep in the galactic core. When the Quasar emerges the pressure is so greatly decreased that it explodes into about 50,000 stars. Proton proton repulsion in large objects, moons, planets, stars, quasars and galaxies are the prime example of anti-gravity in action

- Q: Can aluminum coils be used in corrosive environments?

- No, aluminum coils should not be used in corrosive environments. Aluminum is susceptible to corrosion, especially in the presence of certain chemicals or salts. Therefore, it is recommended to use a more corrosion-resistant material, such as stainless steel, in such environments.

- Q: This question asks about the impact of aluminum coils on the quality of welding. It seeks to understand the relationship between the material properties of aluminum coils and the outcomes of the welding process.

- <p>Aluminum coils can significantly affect welding quality due to their unique properties. Aluminum has a high thermal conductivity, which requires more energy to weld, and can lead to rapid heat dissipation, affecting the weld's uniformity. Oxides on the aluminum surface can also interfere with the welding process, causing porosity and poor joint strength if not properly cleaned. Additionally, aluminum's low melting point can lead to distortion and warping if not managed correctly. The use of appropriate filler materials, proper cleaning, and precise control of welding parameters are crucial to achieve high-quality welds with aluminum coils.</p>

Send your message to us

Coiled Aluminum Prepainted Coil with PVDF/PE 1xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords