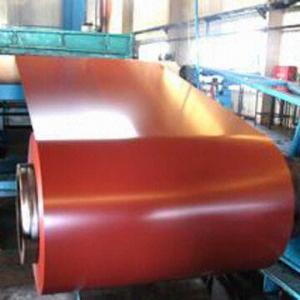

prime prepainted steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | ASTM,JIS | Grade: | hot dipped galvanized steel or Alu-Zic Steel | Thickness: | available from 0.2MM to 0.80MM |

| Place of Origin: | Zhejiang China (Mainland) | Brand Name: | Tiannu | Type: | Steel Coil |

| Technique: | Cold Rolled | Surface Treatment: | Coated | Application: | Boiler Plate |

| Special Use: | Silicon Steel | Width: | available from 914MM to 1250MM | Length: | according to your requirements |

| color: | various |

Packaging & Delivery

| Packaging Detail: | PPGI prepainted galvanized steel sheet/coated steel coils seaworthy package with wooden pallet |

| Delivery Detail: | 20 days after receiving deposit |

Specifications

PPGI prepainted galvanized steel sheet/coated steel coils

1.Prime Quality,Low Price, Efficient Delivery.

2.Free sample.

PPGI prepainted galvanized steel sheet/coated steel coils

Base material: | hot dipped galvanized steel or Alu-Zic Steel |

Standard: | JIS, SGCC, EN, ASTM |

Width: | 914 -1250mm |

Width Tolerance: | within 0.02mm |

Thickness: | 0.20 - 0.80mm |

Thickness Tolerance: | within 0.15MM |

Performance: | Smooth or Matte or anti-scratch |

Color: | according to RAL standard |

Lacquer Coating thickness: | according to customer needs |

Supply capacity: | 7000 Metric Ton per month |

- Q: How are steel coils used in the manufacturing of automotive hoods?

- Steel coils are used in the manufacturing of automotive hoods as they are shaped and cut into specific dimensions to create the hood's structure. These coils are typically formed into panels through processes like stamping, pressing, and forming, which are necessary to achieve the desired shape and strength.

- Q: hello friends, I have some old 7.62x54r on stripper clips its nasty gunk on it can i use steel wool to glean it and still have it fire safely?

- You could, but if you have access to a vibrating case tumbler, it would work much better. I just tumbled a batch of 1,000 of tarnished and dirty Romanian 7.62X25 and it now looks like brand new commercial ammo.

- Q: I asked a question last week about stainless steel and got some great answers. I combed all over the internet to try to figure this one out but could not find anything. What resists bending better: chrome vanadium steel (i.e. a steel commonly used to make tools) or stainless steel 304. My guess would be the chrome vanadium alloy but thats just a guess. Which on resist's bending better and by how much (#'s please :-)). Also, if anyone knows if chrome vanadium steel is cheaper than stainless steel 304 that would be awesome? I can't find a price per pound on chrome vanadium steel anywhere! Please help. Thanks in advance-Josh

- Fill the pot up w/cold water to cover the burned on rice. Bring it up to a boil. Do it again w/some high powered soap in the mix. This time let the water sit in the pan until its luke warm, dump it out and scrub it up w/the plastic scouring pad. You should be all set.

- Q: Is steel easier to weld?Which is more brittle/less flexible?

- You should not attempt to do any traditional welding of steel to aluminum as they can form a hard and brittle inter metallic compound known as iron aluminide. You would have to employ a process that did not melt either species. Cladding could be an option but you are kind of limited to flat products that are sandwiched together. There is also explosive which does almost the same thing as cladding. Friction stir welding might be possible but I cant vouch for that. The temperature does get pretty hot, so I am not sure what would happen. But any of these suggestions would take specialized equipment not available to the average user. For weight, Al is 2.7 g/cc and Iron is about 7.8 so it is about 3 times heavier for the same volume. How strong either of them are greatly depends on specific alloys and heat treatment. I think some of the strongest aluminum alloys have a yield strength of about 50,000 psi which would relate to a relatively weak steel. For steel, there are alloys that can have yield strengths in the hundreds of thousands psi.

- Q: I believe steel is stronger but it steel lighter than iron too?

- Steel is iron, with other things added that strengthen it and/or make it less rust liable. So, in general, steel is stronger than iron. In so far as the density, that depends on the steel alloy. Some are higher than iron, some lower. Remember there are hundreds of different steel alloys. edit: but the density is still close to that of iron. density steel 7750 to 8050 kg/m? density iron 7870 kg/m?

- Q: what is the densest type of steel ? what is its density ?what is its tensile strength .

- Steel weighs 490 lbs/ft3. Then the alloying elements change the density slightly either way depending on their weight. This is the first time I have heard of someone looking for dense steel. Normally they look up the kind of steel based on what properties of the steel they are looking for. ie stainless steel, heat treatable, toughness, etc. Are you sure you are asking the right question?

- Q: How are steel coils used in the production of roofing sheets?

- Steel coils are an essential component in the production of roofing sheets. These coils are typically made from high-quality steel, which is known for its durability, strength, and resistance to corrosion. They undergo a series of processes to transform them into roofing sheets. Firstly, the steel coils are loaded onto a machine called a decoiler, which unrolls the coils and feeds them into the production line. This machine ensures a continuous supply of steel for the manufacturing process. Next, the steel coils pass through a series of rollers, which shape the steel into the desired profile for the roofing sheets. These rollers can create various profiles, such as corrugated or standing seam, depending on the specific requirements of the roofing project. After the shaping process, the steel sheets are often coated with protective layers to enhance their durability. This coating can be in the form of zinc or other metallic alloys, known as galvanized or galvalume coatings, respectively. These coatings provide an additional layer of protection against rust and corrosion. Once the sheets are coated, they are typically cut to the desired length and width. This can be done using shearing machines or other cutting tools, ensuring that the roofing sheets are sized correctly for installation. Finally, the roofing sheets are packaged and prepared for distribution to construction sites. They are often bundled together and securely wrapped to protect them during transportation. In summary, steel coils are crucial in the production of roofing sheets. They undergo shaping, coating, cutting, and packaging processes to transform them into finished products ready for installation. The use of steel coils ensures that roofing sheets are strong, durable, and resistant to various environmental factors, making them a popular choice for roofing applications.

- Q: How are steel coils stored and transported?

- Steel coils are typically stored and transported in a horizontal position, either on the ground or on specially designed racks. They are often secured with steel straps or bands to prevent movement or damage during transportation. When being transported, steel coils are typically loaded onto flatbed trucks or shipping containers using cranes or forklifts. The coils are then secured in place with additional straps or chains to ensure stability during transit.

- Q: Does SA use its own iron ore to produce steel for construction or do we rely on imports?

- Iron ore is just a rock -- in fact it would probably be hard to tell iron ore from a piece you found lying out in your backyard. It's what mines produce, and it needs to be burned to separate it into its different elements. Iron is an element. It is the purest form of the metal. Steel is mostly iron, but it is not pure iron. To make steel you must burn coke (another kind of rock) along with the iron ore. The coke adds carbon to the iron, producing steel which is stronger than pure iron.

- Q: How do steel coils contribute to the water and wastewater industry?

- Steel coils are an essential component in the water and wastewater industry as they play a crucial role in the construction and maintenance of infrastructure. These coils are made from high-quality steel, which offers numerous advantages for the industry. Firstly, steel coils are used in the manufacturing of pipes and tubes that are primarily used for transporting water and wastewater. Steel pipes are known for their exceptional strength and durability, allowing them to withstand high pressure and heavy loads. This makes them ideal for water distribution systems, sewage networks, and treatment plants. Steel coils provide the necessary material for the production of these pipes, ensuring a reliable and long-lasting infrastructure. Moreover, steel coils are also utilized in the construction of storage tanks and reservoirs. These tanks are essential for water treatment plants, where they store large volumes of water or wastewater during the treatment process. Steel coils provide the necessary material for the fabrication of these tanks, ensuring their structural integrity and preventing leaks or contamination. Additionally, steel coils are used in the manufacturing of various equipment and components used in the water and wastewater industry. For instance, steel coils are utilized in the production of pumps, valves, and control systems, which are crucial for the efficient operation of water treatment plants, pumping stations, and sewage networks. Steel's strength and corrosion resistance make it an ideal material for these applications, ensuring reliable and long-lasting equipment. Furthermore, steel coils are also employed in the construction of wastewater treatment plants and facilities. These plants employ various processes to remove contaminants from wastewater before it is discharged into the environment. Steel coils provide the necessary material for the construction of these facilities, including structural supports, tanks, and other components. The durability and resilience of steel ensure the longevity and efficiency of these treatment plants. In summary, steel coils are integral to the water and wastewater industry due to their contribution to the construction and maintenance of critical infrastructure. They are used in the manufacturing of pipes, tanks, equipment, and facilities, ensuring the strength, reliability, and durability necessary for the efficient operation of water and wastewater systems.

Send your message to us

prime prepainted steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords