Vinyl Clad Aluminum Coil - Prepainted Aluminum Coil with PVDF Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Aluminium Coil with PVDF Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the AA5052 Aluminium Wire:

Wood grain-coated aluminum sheet with PVDF and can be used for many fields such as roofing, ceiling, curtain wall, lamp decoration, aluminum composite panel, honeycomb plate, doors and furniture.

Adapts aluminum coil and use best imported paint, composition contains 70% PVDF.

Technology is four coating and two baking.

Surface of products is smooth and dry.

Color is uniform.

Resist UV in air and corrosion.

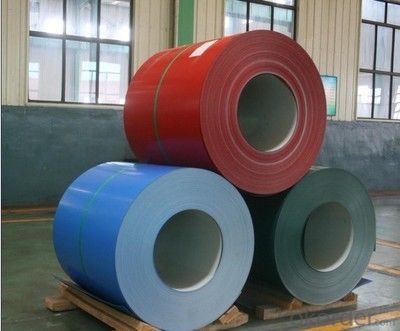

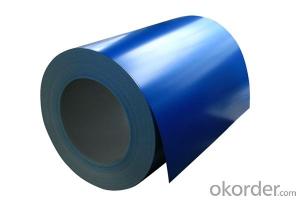

Images of Prepainted Aluminium Coil with PVDF:

Prepainted Aluminium Coil with PVDF Specification:

| product | alloy | temper | size (mm) | ||

| thinckness | width | ||||

| aluminum coil/Color coated al coil/sheet with PE or Pvdf | 1070 1060 1050 1145 1235 1035 1100 1200 3A21 3003 3103 8011 | H18 H14 H16 H22 H24 0 | 1.0-4.0 | 60-1500 | |

FAQ of Prepainted Aluminium Coil with PVDF:

a) What's your process of this type aluminium?

Decoiler → Accumulator→Tension Leveller →Acid&Alkali Cleaner → Rinse →Conversion Treatment → Priming coater →Infrared Curing Oven →Main coater →Floatation Curing Oven →Strippable Film Applicator → Exit Accumulator →Recoiler

b)Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: How do aluminum coils contribute to energy savings in buildings?

- Aluminum coils play a vital role in HVAC systems for buildings, helping to save energy. To start, aluminum coils are highly effective at transferring heat. HVAC systems use these coils to facilitate the exchange of heat between indoor and outdoor environments. Aluminum's thermal conductivity allows for fast and efficient heat transfer, resulting in less energy needed to heat or cool a space. This means that HVAC systems equipped with aluminum coils can achieve the desired indoor temperature more efficiently, leading to energy savings. Furthermore, aluminum coils are lightweight and have excellent corrosion resistance. This property ensures the longevity and durability of the HVAC system, reducing the need for frequent replacements. By lasting longer, the energy and resources used in manufacturing new coils are saved, resulting in reduced energy consumption and environmental impact. Moreover, aluminum coils are highly recyclable. When an HVAC system reaches the end of its life cycle, the aluminum coils can be easily recycled and repurposed. Recycling aluminum requires significantly less energy compared to producing new aluminum from raw materials. By promoting recycling, energy is conserved, and greenhouse gas emissions are reduced. Additionally, aluminum's reflective properties contribute to energy savings in buildings. When used in HVAC systems, aluminum coils can reflect and deflect sunlight, reducing the amount of heat absorbed by the building. This reduces the workload on the HVAC system, resulting in lower energy consumption and increased energy efficiency. In conclusion, the use of aluminum coils in HVAC systems brings about energy savings in buildings due to their high thermal conductivity, lightweight and durable nature, recyclability, and reflective properties. By adopting aluminum coils, buildings can achieve optimal temperature control with reduced energy consumption, leading to significant energy savings and a more sustainable environment.

- Q: Can aluminum coils be used in the production of solar reflectors?

- Yes, aluminum coils can be used in the production of solar reflectors. Aluminum is a common choice due to its high reflectivity and durability, making it suitable for reflecting and directing sunlight efficiently in solar energy systems.

- Q: This question asks for methods to assess the quality of aluminum coils, which is important for various industries that use aluminum for manufacturing and construction.

- <p>To check the quality of aluminum coils, you should inspect for surface defects such as scratches, dents, or discoloration. Measure the thickness and width to ensure they meet specifications. Test the hardness and tensile strength to verify mechanical properties. Conduct a chemical analysis to confirm the alloy composition. Check for internal defects using non-destructive testing methods like ultrasonic testing. Assess the coil's flatness and straightness to prevent issues in further processing. Finally, ensure proper packaging and storage conditions to maintain coil quality.</p>

- Q: How do aluminum coils contribute to sustainable transportation systems?

- Aluminum coils contribute to sustainable transportation systems by being lightweight, durable, and recyclable, which helps reduce the overall weight of vehicles, resulting in improved fuel efficiency and reduced emissions. Additionally, the recyclability of aluminum coils promotes a circular economy, minimizing waste and conserving resources.

- Q: Are there any limitations on the embossing of aluminum coils?

- Yes, there are limitations on the embossing of aluminum coils. The main limitations include the thickness and temper of the aluminum, as well as the complexity and depth of the desired embossing pattern. Additionally, the embossing process may affect the overall flatness and surface quality of the aluminum coil.

- Q: What are the different coil coating options for aluminum coils?

- There are several coil coating options available for aluminum coils, including polyester, polyurethane, fluoropolymer, and plastisol coatings. Each option offers unique benefits, such as durability, weather resistance, and aesthetics, allowing for customization based on specific requirements or desired appearance.

- Q: Can aluminum coils be used in the production of solar panels?

- Yes, aluminum coils can be used in the production of solar panels.

- Q: Can aluminum coils be used for solar panel installations?

- Yes, aluminum coils can be used for solar panel installations. Aluminum is a commonly used material in the solar industry due to its lightweight, durability, and corrosion resistance. Aluminum coils can be used as framing materials for mounting solar panels, providing a sturdy and long-lasting support structure. They also offer excellent heat dissipation properties, which is important for efficient solar panel performance. Additionally, aluminum coils are easy to work with, making the installation process more convenient. Overall, using aluminum coils for solar panel installations is a popular and effective choice.

- Q: This question asks for criteria or methods to determine if a used aluminum coil is safe for reuse.

- <p>To determine if a used aluminum coil is safe to use, consider the following: Check for any visible signs of damage such as cracks, dents, or corrosion. Ensure the coil has been properly cleaned and sanitized to remove any residues or contaminants. Verify that the coil has not exceeded its recommended lifespan or usage limits. Consult the manufacturer's guidelines for any specific safety checks or maintenance requirements. If in doubt, it's best to consult with a professional or replace the coil to avoid potential safety hazards.</p>

- Q: I have heard that aluminum may be a contributing agent in causing Alzheimer's disease, and that if we drink from aluminum cans, that we get aluminum into our system from them. It seems like this would be pretty easy to test in a laboratory, whether or not there are aluminum particles in the contained beverage. But I have heard or read that the inside of the cans are coated with something. So is this just typical uninformed rumors from the Internets, or is there anything to it? Hate to sound rude, but I am not really interested in opinions, like Well I don't think they would sell them if... or Oh yes, I think you get lots of aluminum from it. I am only interested in facts, not gut feelings or opinions.

- It's a fact that the cola industry controls us through microchips floating in their drinks

Send your message to us

Vinyl Clad Aluminum Coil - Prepainted Aluminum Coil with PVDF Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords