prefab steel warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

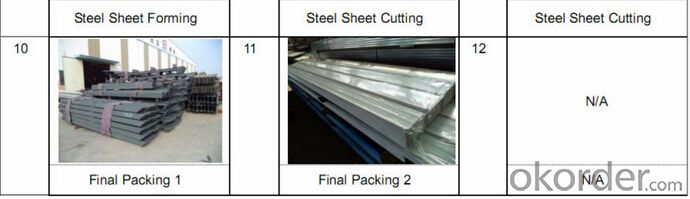

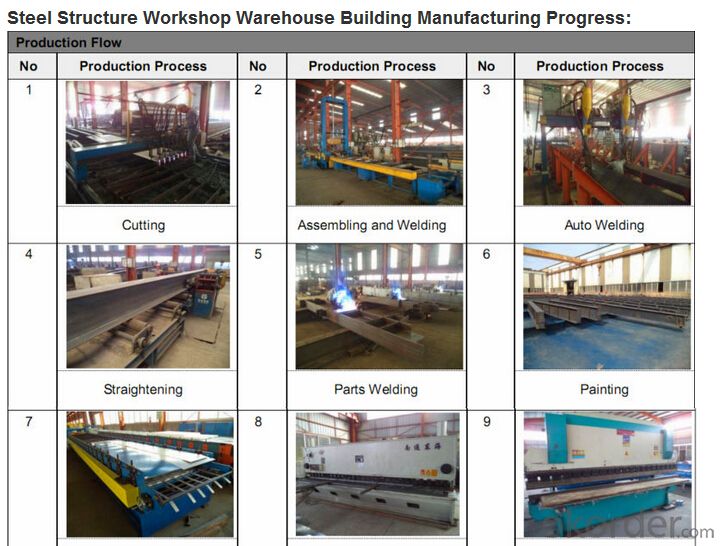

steel structure warehouse/sheds/factory Specifications

Prefabricated House.

Repeat use and long life.

Anti-rust.low cost

| Material | C Purlin, H Beam, Sandwich panel, Hot Galvanised Steel, etc. |

| Features | 1. Firm and Artistic |

| 2. Durable for 30 years at least. | |

| 3. Reusale, and Easy to intall and dismantle: usually, one worker could install 20-30 square meters per day, six workers could work out 3K*10K houses in two days. | |

4. Extensive Applications: Warehouse, Plant, Exhibition Hall, Terminal Building, Stadium, Theater, Special-shaped Buildings. | |

| 5. Hot Galvanised… | |

| 6.Flexible composition: Doors and Windows could be installed at any positions,Separate Walls could be built at any transverse axis. Stairs could be outside Steel buildings. |

- Q: How are steel structures transported and assembled on-site?

- Steel structures are typically transported to the construction site in prefabricated components, such as beams, columns, and panels. These components are delivered by trucks or trains and unloaded using cranes or forklifts. The assembly process involves connecting the various components together using welding or bolting techniques. Skilled workers follow detailed construction drawings and plans to ensure proper alignment and structural integrity. Cranes or other lifting equipment are used to hoist and position the steel components into place. Once all the components are assembled, additional tasks such as welding, painting, and finishing are carried out to complete the steel structure.

- Q: The steel structure housing about how much money.

- If it is a high-rise, it will need to increase the steel beam, then the cost will increase accordingly. Refer to

- Q: How are steel structures designed to withstand snow loads?

- Steel structures are designed to withstand snow loads by carefully considering factors such as the weight of the snow, the shape of the structure, and the local weather conditions. The design takes into account the maximum expected snow load in the area and ensures that the steel members and connections can bear that load without failure. Additionally, the structural system is designed to allow for the shedding of snow, preventing excessive accumulation and reducing the overall load on the structure. The use of appropriate connections, bracing, and reinforcement further enhances the ability of steel structures to withstand snow loads.

- Q: How are steel structures used in the construction of hospitals and healthcare facilities?

- Steel structures are commonly used in the construction of hospitals and healthcare facilities due to their strength, durability, and flexibility. Steel provides a sturdy framework that can support heavy loads and withstand external forces, ensuring the safety of patients, staff, and equipment. It allows for large open spaces, enabling the efficient layout of rooms and medical equipment. Moreover, steel structures can be designed to accommodate future expansions and modifications, allowing healthcare facilities to adapt to changing needs and advancements in medical technology.

- Q: The position of the steel structure requires a spring cushion for mounting the bolt

- Steel structure is mainly made of steel material, and it is one of the main types of building structure. The structure is mainly composed of steel beams and steel plates, such as steel beams, steel columns, steel trusses and so on. Each component or component is usually connected with welds, bolts or rivets. Because of its light weight and simple construction, it is widely used in large factories, stadiums, super high-rise and other fields. The characteristics of the steel is of high strength, light weight, good integral rigidity, deformation ability, it is used in the construction of large span and super high and super heavy buildings especially suitable; homogeneous and isotropic material, an ideal elastic body, the most consistent with the basic assumption of the general engineering mechanics; material has good plasticity and toughness that can have large deformation, can well withstand dynamic loads; short construction period; the high degree of industrialization, can carry out specialized production of high mechanization degree.

- Q: What are the design considerations for steel manufacturing plants?

- There are several important factors to consider when designing steel manufacturing plants. These factors include: 1. Site Selection: The plant's location is crucial and should be chosen based on factors such as proximity to raw materials, availability of utilities and transportation infrastructure, and potential environmental impacts. 2. Layout and Flow: Careful planning of the plant's layout is necessary to ensure efficient material flow and minimize movement of workers and equipment. Optimizing the arrangement of production lines, storage areas, and support services is essential for smooth operations. 3. Equipment Selection: The selection of equipment plays a vital role in steel manufacturing plants. The chosen equipment should be capable of handling the required production capacity, be energy-efficient, and comply with safety and environmental regulations. 4. Safety and Environmental Considerations: Safety is of utmost importance in steel manufacturing plants due to the presence of heavy machinery and high temperatures. Adequate safety measures should be implemented to protect workers from potential hazards. Additionally, incorporating environmental considerations, such as air and water pollution control systems, is necessary to minimize the impact on the surrounding environment. 5. Energy Efficiency: Steel manufacturing is an energy-intensive process. Therefore, it is essential to consider energy-efficient technologies and practices to reduce energy consumption and minimize greenhouse gas emissions. This can include using energy-efficient equipment, implementing waste heat recovery systems, and employing energy management strategies. 6. Maintenance and Accessibility: The plant's design should consider ease of maintenance and accessibility for workers. Providing sufficient space for regular maintenance activities and easy access to equipment for repairs or replacements is important. 7. Scalability and Flexibility: Designing steel manufacturing plants with future expansion and changes in mind is crucial. The layout and infrastructure should allow for easy scalability and flexibility to accommodate changes in production capacity, product types, or technology upgrades. 8. Regulatory Compliance: Steel manufacturing plants must comply with various regulations and standards related to safety, environmental impact, emissions, and labor practices. The design should incorporate these regulations and ensure that the plant operates within legal boundaries. By considering these design factors, steel manufacturing plants can be efficiently and safely designed, ensuring optimal production capacity, minimal environmental impact, and compliance with regulations.

- Q: How are steel structures used in mining and exploration camps?

- Steel structures are commonly used in mining and exploration camps due to their durability, versatility, and ease of construction. They are utilized for various purposes such as accommodation buildings, storage facilities, workshops, and offices. Steel structures provide a reliable and secure environment for workers, equipment, and supplies, ensuring the smooth operation of mining and exploration activities in remote and harsh environments.

- Q: How are steel structures tested for their load-bearing capacity?

- Steel structures are tested for their load-bearing capacity through a process called structural testing. This involves subjecting the structure to various loads, such as static, dynamic, or cyclic loads, to determine its strength and stability. Tests may include applying weights, hydraulic jacks, or computer-controlled equipment to simulate different loads and measure the structure's response. Additionally, non-destructive testing methods like ultrasonic testing or magnetic particle inspection can be used to detect any potential defects or weaknesses in the steel before testing its load-bearing capacity.

- Q: How do steel structures provide resistance against vibration-induced fatigue?

- Steel structures provide resistance against vibration-induced fatigue through a combination of their inherent material properties and design considerations. Firstly, steel has excellent strength and stiffness properties, making it an ideal material for withstanding dynamic forces and vibrations. It has a high modulus of elasticity, which means it can deform elastically under load and return to its original shape once the load is removed. This elasticity helps absorb and dissipate the energy generated by vibrations, reducing the risk of fatigue failure. Additionally, steel structures are designed to have sufficient damping characteristics, which refers to their ability to dissipate vibrational energy. Damping is achieved through the use of various techniques such as adding damping materials or incorporating structural elements that have inherent damping properties. By dissipating energy, damping reduces the magnitude and duration of vibrations, minimizing the potential for fatigue damage. Moreover, steel structures are designed with appropriate stiffness and rigidity to minimize resonance effects. Resonance occurs when the frequency of external vibrations matches the natural frequency of a structure, resulting in amplified vibrations and potential fatigue failure. By designing structures with different natural frequencies or by adding damping elements, the risk of resonance-induced fatigue can be significantly reduced. Furthermore, proper design practices such as ensuring adequate structural support, minimizing stress concentrations, and employing fatigue-resistant details and connections are crucial in preventing fatigue failure. These design considerations distribute stresses more evenly throughout the structure, reducing the likelihood of stress concentrations that can lead to fatigue cracks. In summary, steel structures provide resistance against vibration-induced fatigue through their material properties, such as strength and elasticity, as well as through design considerations such as damping, resonance avoidance, and fatigue-resistant details. By incorporating these factors into the design and construction of steel structures, engineers can ensure their long-term durability and resistance against vibration-induced fatigue.

- Q: How are steel structures designed to accommodate plumbing and HVAC systems?

- Steel structures are often designed with specific consideration for accommodating plumbing and HVAC systems. The design process involves integrating the necessary infrastructure into the steel framework to ensure efficient and effective installation and operation of these systems. To accommodate plumbing systems, structural engineers and architects collaborate with plumbing engineers to determine the optimal routing for pipes and fixtures within the building. This collaboration ensures that the steel structure is designed with appropriate clearances, supports, and access points to accommodate the plumbing system. For example, steel beams may be designed with strategically placed holes or notches to allow pipes to pass through without compromising the structural integrity of the building. Similarly, HVAC systems are carefully integrated into the design of steel structures. The layout and size of ductwork, vents, and equipment are taken into account during the design phase. Structural engineers work closely with HVAC engineers to determine the most efficient routing of ducts and placement of equipment, such as air conditioning units and heating systems. Proper spacing and clearances are provided to ensure that ducts can be installed and maintained effectively. In addition to the initial design, steel structures also incorporate flexibility to accommodate future modifications or expansions to plumbing and HVAC systems. This flexibility is crucial as building requirements may change over time. By allowing for easy access and modifications, steel structures provide cost-effective solutions for future renovations or upgrades to the plumbing and HVAC systems. Overall, the design of steel structures takes into account the specific needs of plumbing and HVAC systems. Through collaboration between structural engineers and plumbing/HVAC engineers, the steel framework is tailored to accommodate these systems efficiently, ensuring optimal functionality, accessibility, and adaptability.

Send your message to us

prefab steel warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords