precio de 1 kg acero inoxidable 304/310

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Square

Surface Treatment:

Polished

Steel Grade:

300 Series

Certification:

SGS

Thickness:

0.5

Width:

1219

Length:

2438

Net Weight:

12

precio de 1 kg acero inoxidable

You May Interest

| Mill and Origin? |

| Tisco(Shanxi), BAOSTEEL(Shanghai), ZPSS(ZhangJiagang) |

| Certificate of the Goods? |

| MTC would be offered by factory after preparation of the material |

| Do You Have These Goods in Stock? |

| If the dimensions are regular,we have in stock, but some special sizes need to be ordered |

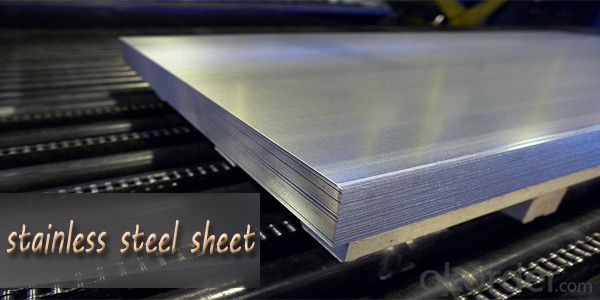

Product Description

| Item | precio de 1 kg acero inoxidable | |||

| Standard | ASTM,AISI,JIS,EN,DIN,GB | |||

| Surface | 2B | |||

| Thickness | 0.3-6mm | |||

| Width | 1000,1219mm or as customer’s requires. | |||

| Length | As customer’s requirements. | |||

| Edge | Slit/Mill Edge | |||

| Origin | TISCO,LISCO,JISCO,BAOSTEEL,BAOXIN, Eastern Special Steel etc. | |||

| MOQ | 2 Tons | |||

| Payment Term | 30%T/T; L/C at sight | |||

| Price Term | FOB/CFR/CIF | |||

| Delivery | 7-10 days after the deposit | |||

| Packaging | Seaworthy Export Standard or as customer's requests. | |||

| Application | construction field;ship building industry;petroleum and chemical industries;war and electricity industries;food processing and medicalindustry; boiler heat exchanger; machinery and hardware industry | |||

Product Show

- Q: Are stainless steel sheets resistant to pitting?

- Yes, stainless steel sheets are resistant to pitting. Stainless steel has a high resistance to corrosion, including pitting corrosion, due to its chromium content which forms a protective oxide layer on the surface. This makes stainless steel sheets a durable and reliable material for various applications where resistance to pitting is important.

- Q: What is the price per square foot for stainless steel sheets?

- The price per square foot for stainless steel sheets can vary depending on various factors such as the grade, thickness, finish, and supplier. On average, stainless steel sheets can range from $3 to $10 per square foot. However, high-quality and specialty stainless steel sheets can be priced higher, reaching up to $20 or more per square foot. It is important to consider these factors and shop around to find the best price for your specific requirements.

- Q: Can stainless steel sheets be used for decorative elevator doors or panels?

- Indeed, stainless steel sheets are perfectly suitable for adorning elevator doors or panels in a decorative manner. The versatility of stainless steel as a material is unparalleled, as it not only bestows an exquisite and contemporary appearance but also enjoys great popularity for its decorative applications. Its exceptional durability, resistance to corrosion, and effortless maintenance make it an ideal choice for areas with heavy foot traffic, such as elevator doors and panels. Moreover, stainless steel sheets can be tailored to one's specific preferences by incorporating a wide range of finishes, patterns, and textures, thereby offering limitless design possibilities. Whether one desires a sleek and minimalist aesthetic or a more intricate and decorative motif, stainless steel sheets can elevate the visual appeal of elevator doors and panels while providing enduring functionality.

- Q: What are the different types of stainless steel sheet coatings available?

- There are several different types of stainless steel sheet coatings available, each offering unique properties and benefits. Some of the most common types include: 1. Galvanized Coatings: These coatings are made by applying a layer of zinc to the surface of the stainless steel sheet. This helps to protect the steel from corrosion and rusting. Galvanized coatings are commonly used in outdoor applications or in environments where the steel is exposed to moisture or chemicals. 2. Powder Coatings: Powder coatings are a popular choice for stainless steel sheets as they provide excellent durability and resistance to corrosion. This type of coating is applied as a dry powder and then heated to form a hard protective layer. Powder coatings come in a variety of colors and finishes, allowing for customization and aesthetic appeal. 3. Electroplating: Electroplating involves the deposition of a thin layer of another metal onto the stainless steel sheet. Common metals used for electroplating include chrome, nickel, and zinc. This coating not only enhances the appearance of the steel but also improves its resistance to corrosion and wear. 4. PVD Coatings: Physical Vapor Deposition (PVD) coatings involve the deposition of a thin film onto the stainless steel sheet using a vacuum process. These coatings can provide various properties such as improved hardness, scratch resistance, and color options. PVD coatings are commonly used in architectural applications or for decorative purposes. 5. Organic Coatings: Organic coatings, such as paints or lacquers, can also be applied to stainless steel sheets. These coatings provide an additional layer of protection against corrosion, as well as offering aesthetic options. Organic coatings are often used in applications where color matching or branding is important. Each type of stainless steel sheet coating has its advantages and is suitable for specific applications. The choice of coating will depend on factors such as the intended use, desired appearance, and environmental conditions in which the stainless steel will be exposed. It is important to carefully consider these factors and consult with experts to choose the most suitable coating for your specific needs.

- Q: Can stainless steel sheets be used for countertops or backsplashes?

- Certainly! Countertops and backsplashes can indeed be made from stainless steel sheets. This material is highly durable and can resist stains, heat, and bacteria, which makes it an exceptional option for kitchen surfaces. It is simple to clean, maintains its appearance throughout time, and can endure heavy usage. Not only are stainless steel countertops and backsplashes widely used in commercial kitchens because of their hygienic qualities, but they are also gaining popularity in residential settings due to their stylish and contemporary appearance.

- Q: Can stainless steel plate spray paint?

- Spray (brush) primer, the role of primer, first, to prevent the oxidation of metal surface, and two is the top coat and metal firmly linked together. There are several kinds of primer. In the local paint shop a dozen could get answers.

- Q: Can stainless steel sheets be used for elevator frames?

- Yes, stainless steel sheets can be used for elevator frames. Stainless steel is a preferred material for elevator frames due to its strength, durability, and resistance to corrosion, making it suitable for withstanding the regular wear and tear of elevator usage.

- Q: Are stainless steel sheets good for heat exchanger tubes?

- Stainless steel sheets are widely employed as heat exchanger tubes owing to their remarkable heat transfer capabilities and resistance to corrosion. The thermal conductivity of stainless steel is notably high, enabling efficient heat transfer between fluids. Moreover, its exceptional resistance to corrosion is vital for heat exchangers that frequently encounter corrosive liquids or gases. The longevity and reliability of stainless steel sheets guarantee the durability of heat exchanger tubes, making them a favored option in diverse industries like chemical processing, power generation, and HVAC systems.

- Q: How do you remove water spots from stainless steel sheets?

- To remove water spots from stainless steel sheets, you can follow these simple steps: 1. Start by thoroughly cleaning the surface with a mild dish soap and warm water solution. This will remove any dirt or grime that may be contributing to the appearance of water spots. 2. Rinse the sheets with clean water and dry them completely using a soft cloth or towel. This step is important to prevent any new water spots from forming during the cleaning process. 3. Next, prepare a solution of equal parts white vinegar and water. Dip a clean cloth or sponge into the solution and wring out any excess liquid. 4. Gently rub the affected areas of the stainless steel sheets with the vinegar solution-soaked cloth or sponge. Be sure to follow the grain of the stainless steel to avoid scratching the surface. 5. After rubbing the water spots, rinse the sheets with clean water and dry them thoroughly once again with a soft cloth or towel. 6. If the water spots persist, you can try using a stainless steel cleaner or polish specifically designed for removing stains and water spots. Follow the instructions provided with the cleaner, and be sure to test it on a small, inconspicuous area first to ensure it does not damage the stainless steel. Remember to always use soft materials and gentle cleaning techniques when dealing with stainless steel to avoid scratching or damaging the surface.

- Q: How do you prevent rusting on stainless steel sheets?

- To prevent rusting on stainless steel sheets, you can implement a few preventive measures such as keeping the sheets clean and dry, avoiding exposure to corrosive substances, applying a protective coating or passivation treatment, and ensuring proper ventilation to minimize moisture buildup.

Send your message to us

precio de 1 kg acero inoxidable 304/310

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords