Stainless Steel Sheet price per kg AISI310 / 310S

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

| 1 | Item | Stainless Steel Sheet price per kg AISI310 / 310S |

| 2 | Material | ASTM 201,ASTM202,

ASTM 301, ASTM304,ASTM304L, ASTM 316, ASTM310 ASTM316L,ASTM316Ti,ASTM309S, ASTM310S, ASTM321, ASTM347H, ASTM A317,ASTMA317L,

ASTM409,ASTM409L,ASTM410,ASTM420,ASTM430 |

| 3 | Technique | Cold Rolled Stainless Steel Plate; Cold Drawn Stainless Steel Plate; Hot Rolled Stainless Steel Plate; |

| 4 | Standard | ASTM,AISI,ASME,JIS,SUS,DIN,EN,GB,BS |

| 5 | Thickness | 0.1mm-200mm |

| Width | 1000mm,1219mm(4feet),1250mm,1500mm,1524mm(5feet),1800mm, 2200mm or as you require | |

| Length | 2000mm,2440mm(8feet),2500mm,3000mm,3048mm(10feet),5800mm, 6000mm or as requirements | |

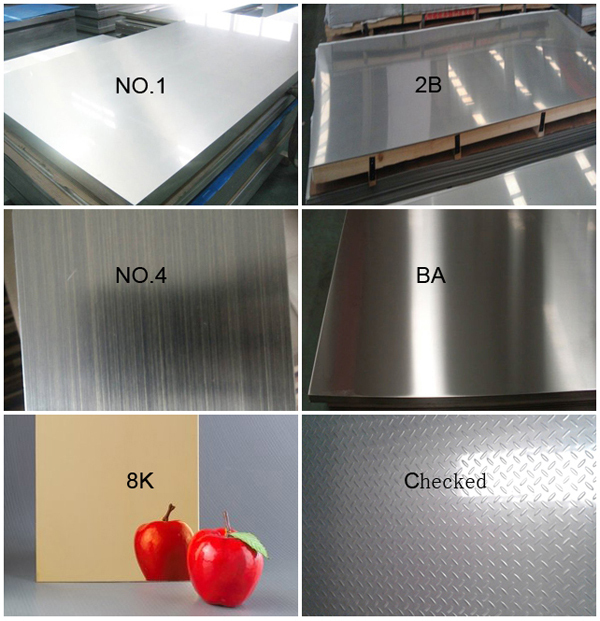

| 6 | Surface Treatment | No.1, NO.4 ,2B, BA, Hair Line,8K,Brush,Embossed and Mirror Finish or as your demand |

| 7 | Packing | Standard export packing-For stainless steel plate

1. bundle package 2. wooden case ,wooden pallet package 3:container or bulk 4. special according to customer request |

| 8 | Delivery | Normally according to the order quantity or upon negotiation |

| 9 | Price Item | EXW,FOB,CFR,CIF,DAF Or as negotiated |

10 | Application | Stainless Steel sheets are widely used in below fields:

1: Construction feild,shipping building industry 2: Petroleum and Chemical Industries 3: Food and Machenical Industries 4: Boiler Heat Exchange 5: Machinery and Hardware Industries |

| 11 | Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. |

| 12 | Export | Our stainless steel sheets are export Southeast Asia, Mid East, Africa, Eastern Asia,Western Europe and So on. |

| 13 | Certificate | We are BV and TUV audited company |

| 14 | Contact | If you have any question,please feel free to contact me. |

Our Services

Surface Finished | Characteristics | Application |

BA | Bright heat treatment after cold rolling. | Kitchen utensil, Kitchen ware, Architectural purpose. |

2B | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to more brighter and smooth surface. | General application medical instruments, Tableware. |

NO.1 | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface. | Chemical industry equipment, Industrial tanks. |

8K(mirror) | A mirror-like reflective surface by polishing with finer abrasives over 800 mesh. | Refletor, Mirror, Interior- Exterior decoration for building. |

Hair Line | Finished by continuous linear polishing. | Architecture industries, Escalators, Kitchen ware, Vehicles. |

- Q: What are the different types of stainless steel sheet edges?

- Stainless steel sheets come in three main types of edges: mill edge, slit edge, and deburred edge. 1. The mill edge is the most common type and is produced during manufacturing. It has a rough, unfinished edge that is typically straight and perpendicular to the sheet's surface. It is suitable for applications where a smooth edge is not necessary. 2. Slit edge sheets are created by cutting large rolls of stainless steel into narrower widths. These edges are smoother and more precise compared to the mill edge. They are commonly used in applications that require a polished and precise edge, such as architectural finishes or fabrication processes. 3. A deburred edge is achieved by removing any sharp or rough edges from the stainless steel sheet. This is done to improve safety during handling or installation. Deburring can be done through grinding, sanding, or using specialized tools. The resulting edge is smooth and free from burrs or sharp protrusions. It's important to consider the specific application and requirements when choosing the edge type for a stainless steel sheet. Each type has its own advantages and limitations, and factors like aesthetics, functionality, and safety should be taken into account when selecting the appropriate edge for a project.

- Q: How do I prevent crevice corrosion on stainless steel sheets?

- To prevent crevice corrosion on stainless steel sheets, it is important to keep them clean and free from contaminants. Regularly cleaning the sheets with a mild detergent and water, followed by thorough drying, can help remove any corrosive agents. Additionally, ensuring proper ventilation and avoiding prolonged exposure to high humidity or stagnant conditions can minimize the risk of crevice corrosion. Applying a protective coating or using corrosion inhibitors specifically designed for stainless steel can provide an extra layer of protection against crevice corrosion.

- Q: Can stainless steel sheets be used for flooring?

- Certainly, flooring can indeed be made using stainless steel sheets. Stainless steel, being a sturdy and adaptable substance, possesses resistance against corrosion, stains, and scratches, thereby rendering it fitting for areas with heavy foot traffic. It is frequently employed in commercial and industrial environments like hospitals, kitchens, and food processing plants, where cleanliness and hygiene hold paramount importance. Stainless steel flooring imparts a polished and contemporary appearance, is effortless to clean and maintain, and can endure substantial loads and extreme temperatures. Furthermore, stainless steel sheets can be personalized to suit any area and can be installed with different finishes to augment slip resistance.

- Q: What are the common sizes of stainless steel sheets?

- The common sizes of stainless steel sheets vary, but some common dimensions include 4 feet by 8 feet, 5 feet by 10 feet, and 4 feet by 12 feet.

- Q: Are stainless steel sheets suitable for pharmaceutical cleanrooms?

- Yes, stainless steel sheets are highly suitable for pharmaceutical cleanrooms. Stainless steel is widely used in the pharmaceutical industry due to its excellent resistance to corrosion, durability, and ease of cleaning. It is a non-porous material that does not harbor bacteria or contaminants, making it ideal for cleanroom environments where maintaining a sterile and hygienic environment is crucial. Stainless steel sheets are also easy to sanitize and withstand harsh cleaning agents without deteriorating or releasing particles that could contaminate the pharmaceutical products being manufactured. Additionally, stainless steel has a smooth and non-shedding surface, which prevents the accumulation of particles and facilitates cleanroom maintenance. Overall, stainless steel sheets are an excellent choice for pharmaceutical cleanrooms to ensure compliance with strict cleanliness and sterility requirements.

- Q: What is the cost of stainless steel sheets?

- The cost of stainless steel sheets can vary depending on several factors such as the thickness, size, and grade of stainless steel being used. Generally, stainless steel sheets are priced per square foot or per square meter. The price range can also depend on the supplier, location, and market conditions. Additionally, any additional processing or finishing required, such as polishing or cutting, can also affect the cost. It is recommended to contact a local supplier or distributor to get accurate and up-to-date pricing information for stainless steel sheets.

- Q: Are stainless steel sheets suitable for medical equipment?

- Indeed, medical equipment can be fabricated using stainless steel sheets. The utilization of stainless steel in medical equipment is widely favored due to its remarkable resistance to corrosion and its ability to endure. It boasts effortless cleaning and sterilization, rendering it fitting for employment in healthcare facilities where cleanliness and hygiene are paramount. Furthermore, the high strength-to-weight ratio of stainless steel permits the creation of lightweight yet robust medical equipment. Moreover, its magnetic permeability is low, rendering it an ideal option for situations necessitating minimal electromagnetic interference. All in all, stainless steel sheets are a dependable and pragmatic selection for the production of medical equipment.

- Q: Can stainless steel sheets be used for elevator handrails or grab bars?

- Stainless steel sheets are indeed suitable for elevator handrails or grab bars. These applications often favor stainless steel due to its commendable durability, resistance to corrosion, and pleasing appearance. One can fashion stainless steel sheets into different forms and dimensions to meet the precise demands of elevator handrails or grab bars, guaranteeing the safety and comfort of users. Moreover, stainless steel is effortlessly cleaned and maintained, making it a logical preference for frequently-used spaces like elevators.

- Q: What is the electrical conductivity of stainless steel sheets?

- The electrical conductivity of stainless steel sheets can vary depending on the specific grade and composition of the stainless steel. Generally, stainless steel is not known for its high electrical conductivity compared to other metals such as copper or aluminum. However, it still possesses some level of electrical conductivity. The electrical conductivity of stainless steel is typically lower than that of most metals because it contains a higher proportion of non-conductive elements such as chromium and nickel. Stainless steel is often chosen for its corrosion resistance rather than its electrical conductivity. However, it can still be used in certain electrical applications where moderate conductivity is acceptable.

- Q: What are the different types of textured finishes available for stainless steel sheets?

- Stainless steel sheets offer a variety of textured finishes, each with its own unique appeal and functional advantages. Among the most commonly used finishes are: 1. Brushed Finish: This popular finish involves brushing the surface of the stainless steel sheet with abrasive materials, resulting in parallel lines that give a smooth and sophisticated appearance while also concealing scratches and fingerprints. 2. Embossed Finish: With this finish, a raised pattern is stamped onto the stainless steel sheet, adding depth and visual interest. Embossed finishes can range from simple designs like diamonds or squares to more intricate patterns. 3. Bead Blast Finish: Achieved by blasting the stainless steel sheet with fine glass beads or ceramic particles at high pressure, this finish creates a uniform matte appearance with a slightly rough texture. It is often used for decorative purposes, offering a contemporary and unique look. 4. Linen Finish: Also known as a cross-hatch finish, the linen finish features fine parallel lines that intersect, resembling the texture of linen fabric. This finish is achieved through mechanical rolling or brushing and provides both visual appeal and scratch resistance. 5. Satin Finish: Similar to the brushed finish, the satin finish is achieved by brushing the stainless steel sheet with abrasive materials. However, it has a smoother appearance with less pronounced parallel lines. It offers a subtle shine and a refined look, making it a popular choice for architectural and decorative applications. 6. Hammered Finish: This texturized finish is created by hammering the stainless steel sheet with a ball-peen hammer or a similar tool, resulting in a unique hammered pattern. It adds a rustic and artisanal touch, commonly used in interior design and decorative applications. In summary, the choice of textured finish for stainless steel sheets depends on the desired aesthetics, functionality, and application. Each finish has its own distinct appearance and can enhance the visual appeal of stainless steel while also providing additional benefits, such as scratch resistance and fingerprint hiding.

Send your message to us

Stainless Steel Sheet price per kg AISI310 / 310S

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords