Geomembrana Precio M2

Geomembrana Precio M2 Related Searches

Geomembrana Precio M2 México Precio De Geomembrana Por M2 Geomembrana Precio M2 Colombia Harga Geomembrane Per M2 Precio De Geomembrana Geomembrana Precio Mexico Precio De La Geomembrana Geomembrana De 1 Mm Precio Geomembrana 1.5 Mm Precio Geomembrana Pvc Precio Geomembrane Price Precios De Geomembrana En Mexico Geomembrana De Pvc Precio Harga Geomembrane Cuanto Cuesta La Geomembrana Tanques De Geomembrana Precios Rollo De Geomembrana Precio Venta De Geomembrana Geomembrana 1 Mm Geomembrane Cost Estanques De Geomembrana Precios Geomembrane Liner Price Geomembrana Home Depot Harga Geomembrane Per Roll Venta De Geomembrana En Mexico Geomembrane Cost Per Square Foot Buy Geomembrane Geomembrane For Sale Geomembrana Mexico Geomembrana Para TechosGeomembrana Precio M2 Supplier & Manufacturer from China

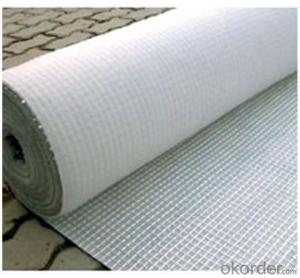

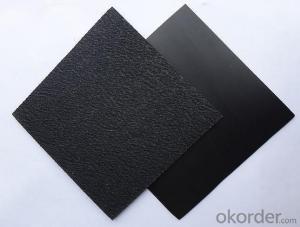

Geomembrana Precio M2 is a high-quality geomembrane product designed for various applications in the construction and environmental industries. This product is known for its durability, flexibility, and resistance to various environmental factors, making it an ideal choice for projects that require reliable waterproofing and containment solutions.The usage of Geomembrana Precio M2 spans across a wide range of scenarios, including landfill liners, pond liners, reservoirs, canals, and other water management systems. Its versatility allows it to be used in both civil engineering and environmental protection projects, providing an efficient and cost-effective solution for a variety of waterproofing and containment needs. The product's ability to withstand harsh conditions and resist chemical degradation makes it a popular choice among professionals in the field.

Okorder.com is a reputable wholesale supplier of Geomembrana Precio M2, boasting a large inventory to cater to the demands of various projects. As a leading distributor, Okorder.com ensures that customers receive the highest quality products at competitive prices, with the convenience of a one-stop shopping experience. By partnering with Okorder.com, customers can be confident in the reliability and performance of their Geomembrana Precio M2, knowing that they are backed by a trusted supplier with a commitment to excellence.

Hot Products