Precio De Geomembrana

Precio De Geomembrana Related Searches

Precio De La Geomembrana Geomembrana De Pvc Precio Precios De Geomembrana En Mexico Precio De Geomembrana Por M2 Geomembrana De 1 Mm Precio Cuanto Cuesta La Geomembrana Rollo De Geomembrana Precio Geomembrane Price Tanques De Geomembrana Precios Geomembrana Precio Mexico Harga Geomembrane Geomembrana Precio M2 Geomembrana Pvc Precio Venta De Geomembrana Estanques De Geomembrana Precios Harga Geomembrane Per M2 Geomembrana 1.5 Mm Precio Geomembrane Cost Geomembrane Liner Price Harga Geomembrane Per Roll Geomembrana Precio M2 México Venta De Geomembrana En Mexico Geomembrana Precio M2 Colombia Venta De Geomembrana En Honduras Geomembrane Cost Per Square Foot Venta De Geomembrana En Lima Geomembrana Hdpe 1 Mm Precio Geomembrana De Pvc Venta De Geomembrana En Puebla Geomembrana Home DepotPrecio De Geomembrana Supplier & Manufacturer from China

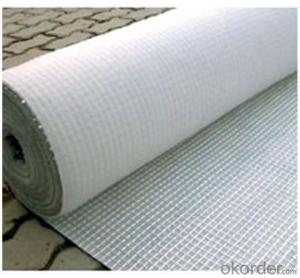

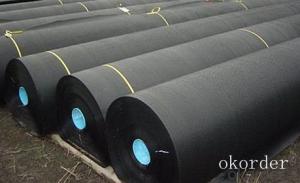

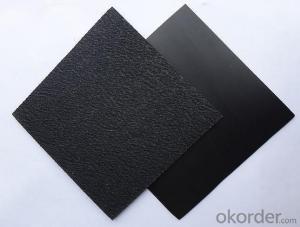

Precio De Geomembrana offers a variety of high-quality geomembrane products, including HDPE, LLDPE, and PVC materials. These geomembranes are widely used in various applications such as landfill liners, water reservoirs, canal linings, and other civil engineering projects. They provide excellent waterproofing and sealing properties, ensuring the integrity and safety of the structures they are used in.Geomembranes from Precio De Geomembrana are utilized in a multitude of scenarios, providing efficient solutions for environmental protection and construction projects. They are designed to withstand harsh conditions and resist chemical degradation, making them ideal for long-term use in various industries. The versatility of these products allows them to be tailored to specific project requirements, ensuring optimal performance and durability.

Okorder.com is a leading wholesale supplier of Precio De Geomembrana products, boasting a large inventory that caters to the diverse needs of customers worldwide. By offering competitive prices and reliable service, Okorder.com ensures that clients have access to the geomembrane products they require for their projects. This commitment to quality and customer satisfaction has made Okorder.com a trusted source for geomembrane solutions in the global market.

Hot Products