Price of 1kg 304 price Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description

Price of 1kg stainless steel sheet

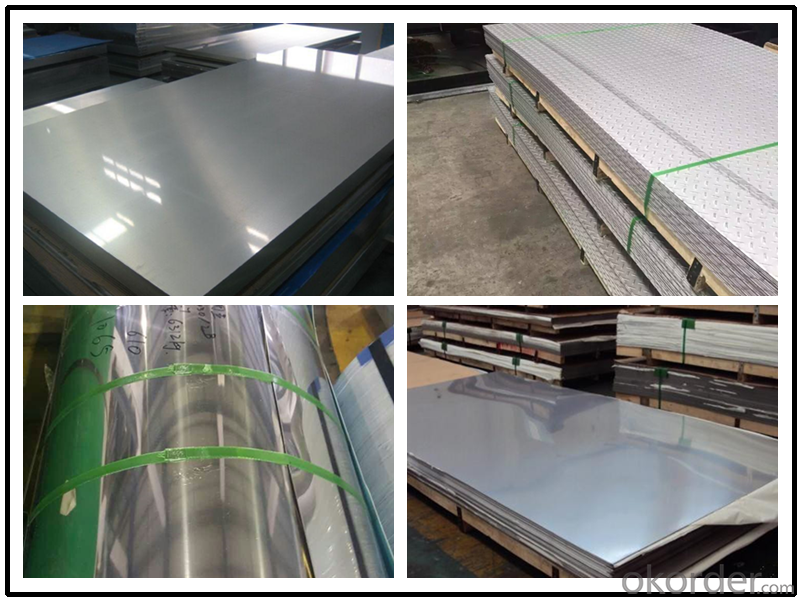

Thickness: 0.3-60mm

Width: 600-2000mm

Surface: No.1, 2B, Hairline, No.4, BA, 8K mirror finish

( material grades we can supply including: 304 / 304L / 201 / 316L / 321 / 310S / 430 / 410 / 410S / 409L / 409)

Product name | Price of 1kg stainless steel sheet |

Standard | ASTM, AISI, JIS, GB, DIN |

Mill | TISCO , LISCO, ZPSS, BAOSTEEL, SKS |

Certification | ISO Certificate, Mill Test Certificate |

MOQ | 1 Metric Ton |

Terms of delivery | FOB, CFR, CIF |

Time of shipment | Normally delivery within 10 days from stocks. |

Stocks | Ready In stocks |

Chemical Composition | ||||

SS304 | SS 316 | SS430 | SS201 | |

Ni(%) | 8.0-10.5 | 10.0-14.0 | -- | 0.8-1.2 |

Cr(%) | 18.0-20 | 16.0-18.0 | 16.0-18.0 | ≤0.15 |

C(%) | ≤0.08 | ≤0.08 | ≤0.12% | ≥40 |

Elong(%) | ≥40 | ≥40 | ≥22 | |

Hardness | HB≤187,HRB≤90, HV≤200 | HB≤187, HRB≤90 HV≤200 | HB≤183, HRB≤88 HV≤200 | HB≤241,HRB≤100, HV≤240 |

Stainless Steel Sheet Series

Stainless Steel Polished Sheet (8K Mirror, Hairline, Grit 240,320)

Embossed Stainless Steel Sheet

Etched Stainless Steel Sheet,

PVD Colored Stainless Steel Sheet,

Perforated Stainless Steel Plate

Chequered Stainless Steel Sheet

Packaging & Shipping

Application

- Q: What are the different types of stainless steel sheet surface coatings for outdoor applications?

- Outdoor applications commonly use various types of stainless steel sheet surface coatings. These coatings aim to enhance the stainless steel's durability and corrosion resistance, making it suitable for harsh outdoor environments. One commonly used coating for outdoor applications is powder coating. This involves applying a dry powder to the stainless steel surface and then curing it under heat to create a protective layer. Powder coating offers excellent resistance against corrosion, UV rays, and chemicals, making it perfect for outdoor use. Furthermore, it provides a wide range of color options, allowing for customization and aesthetic appeal. Another type of coating frequently employed for outdoor applications is PVD (Physical Vapor Deposition) coating. This process entails depositing a thin film of material onto the stainless steel surface using a vacuum chamber. PVD coatings offer outstanding adhesion, wear resistance, and corrosion resistance, making them suitable for outdoor use. They also provide various decorative finishes like gold, bronze, or black, which can enhance the stainless steel's appearance. In addition, stainless steel can be coated with ceramic for outdoor applications. Ceramic coatings are typically applied using a high-temperature spray process, resulting in a hard, protective layer on the stainless steel surface. These coatings offer superior resistance against abrasion, chemicals, and UV rays, making them ideal for highly durable outdoor applications. To summarize, stainless steel sheet surface coatings for outdoor applications include powder coating, PVD coatings, and ceramic coatings. Each of these coatings offers distinct benefits in terms of corrosion resistance, durability, and aesthetic appeal, enabling the use of stainless steel in a wide range of outdoor environments.

- Q: Are stainless steel sheets suitable for welding or fabrication?

- Yes, stainless steel sheets are suitable for welding and fabrication. Stainless steel has excellent weldability, which means it can be easily fused together using various welding techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. It also has good formability, allowing it to be easily shaped and fabricated into different structures or components. Additionally, stainless steel sheets offer high strength and corrosion resistance, making them a popular choice in industries such as construction, automotive, and manufacturing. Overall, stainless steel sheets are a versatile and reliable material for welding and fabrication applications.

- Q: Can stainless steel sheets be used for heat recovery systems?

- Heat recovery systems can utilize stainless steel sheets. Stainless steel is known for its high thermal conductivity and corrosion resistance, making it an ideal material for heat transfer applications. In heat recovery systems, stainless steel sheets are commonly employed as heat exchanger plates or tubes because they efficiently transfer heat from one fluid to another. The corrosion resistance of stainless steel guarantees the durability and reliability of the heat recovery system, even in harsh environments and at elevated temperatures. Furthermore, stainless steel sheets can withstand thermal expansion and contraction, enabling their use in different heat recovery system designs. Overall, stainless steel sheets are a favored option in heat recovery systems due to their exceptional heat transfer properties, long-lasting nature, and resistance to corrosion.

- Q: Are stainless steel sheets suitable for automotive grilles or trim?

- Automotive grilles or trim can be effectively improved by using stainless steel sheets. This material is highly durable and resistant to corrosion, making it suitable for withstanding the challenging conditions found in the automotive environment. These conditions include exposure to moisture, road salt, and fluctuating temperatures. Stainless steel is also renowned for its strength, providing excellent protection to the front end of vehicles. What's more, stainless steel sheets can be easily shaped and molded into different designs and forms to meet the specific style requirements of automotive grilles or trim. Additionally, stainless steel possesses an attractive aesthetic appeal that can enhance the overall appearance of the vehicle. In summary, the utilization of stainless steel sheets for automotive grilles or trim guarantees long-lasting durability, functionality, and a refined look.

- Q: What is the maximum length available for stainless steel sheets?

- The maximum length available for stainless steel sheets can vary depending on the supplier and the specific grade of stainless steel. However, in general, stainless steel sheets are commonly available in lengths ranging from 96 inches (8 feet) to 240 inches (20 feet). Some suppliers may offer even longer lengths, such as 300 inches (25 feet), for specific applications or upon request. It is important to check with the supplier to determine the maximum length available for the specific stainless steel sheet you require.

- Q: Is there any magnetism in 304 stainless steel?

- This doesn't mean it is not qualified, because the most commonly used stainless steel decorative tube plate is Austenitic 304 material is generally non-magnetic or weakly magnetic, but fluctuations in chemical composition caused by smelting or processing of different magnetic properties may also appear, so it can not be considered to be counterfeit or substandard.

- Q: How do you determine the grade of a stainless steel sheet?

- Multiple factors must be taken into account in order to determine the grade of a stainless steel sheet. Firstly, it is necessary to analyze the composition of the stainless steel. Stainless steel is typically composed of a combination of metals, including iron, chromium, nickel, and other elements. The specific percentages of these metals will dictate the grade of the stainless steel. For example, a stainless steel sheet with higher levels of chromium and nickel will generally have a higher grade. The mechanical properties of the stainless steel are also an important consideration. These properties encompass the tensile strength, yield strength, and elongation of the material. Different grades of stainless steel will exhibit varying mechanical properties, which can be assessed using standardized testing methods. Surface finish is another factor that contributes to determining the grade of a stainless steel sheet. The finish can range from rough and dull to smooth and polished. Specific surface finishes may be associated with different grades of stainless steel, and this can be confirmed through visual inspection or the use of specialized equipment. Furthermore, the corrosion resistance of the stainless steel sheet plays a significant role in its grade determination. Stainless steel is renowned for its resistance to corrosion, and higher grades of stainless steel generally offer superior resistance to various corrosive environments. Corrosion testing methods, such as salt spray testing, can aid in evaluating the corrosion resistance of a stainless steel sheet. In conclusion, the grade of a stainless steel sheet can be determined by analyzing its composition, mechanical properties, surface finish, and corrosion resistance. By considering these factors, one can accurately ascertain the grade of a stainless steel sheet and assess its suitability for specific applications.

- Q: Can stainless steel sheets be cut or shaped?

- Yes, stainless steel sheets can be cut or shaped using various methods such as shearing, laser cutting, plasma cutting, or forming processes like bending, rolling, or stamping.

- Q: How do I prevent fretting corrosion on stainless steel sheets?

- To prevent fretting corrosion on stainless steel sheets, there are several preventive measures that can be taken: 1. It is crucial to handle stainless steel sheets properly, avoiding any scratching or rubbing of the surface that could lead to fretting corrosion. Gloves should be worn and contact with other metals or rough surfaces should be avoided. 2. Regular cleaning of the stainless steel sheets using mild detergents or specialized stainless steel cleaners is recommended. This helps to remove contaminants that can initiate corrosion and prevents the build-up of dirt or grime that can contribute to fretting corrosion. 3. Applying a suitable lubricant or anti-seize compound on the contact surfaces can minimize friction and prevent fretting corrosion, especially in applications with repeated movement or vibration. 4. Whenever possible, it is advised to isolate stainless steel sheets from direct contact with other metals. This can be achieved by using insulating materials, gaskets, or non-metallic spacers to create a barrier between the stainless steel and potentially corrosive materials. 5. Regular inspection of the stainless steel sheets is important to detect any signs of fretting corrosion, such as small cracks, discoloration, or pitting. Early detection allows for prompt action to prevent further damage. 6. Applying a protective coating, such as a passivation treatment or a corrosion-resistant paint, can provide an additional layer of protection against fretting corrosion. It is recommended to consult with a professional to determine the most suitable coating for the specific application. 7. Proper storage of stainless steel sheets is essential. When not in use, they should be stored in a clean, dry environment to minimize exposure to moisture or corrosive substances. The storage area should be well-ventilated and free from any contaminants that could potentially initiate fretting corrosion. By following these preventive measures, the risk of fretting corrosion on stainless steel sheets can be significantly reduced, ultimately prolonging their lifespan.

- Q: What's the difference between galvanized steel and stainless steel?

- The corrosion resistance of stainless steel decreases with the increase of carbon content. Therefore, the carbon content of most stainless steel is lower, the maximum is not more than 1.2%, and the Wc (carbon content) of some steel is even lower than 0.03% (such as 00Cr12). The main alloying element in stainless steel is Cr (chromium), which is corrosion resistant only when the Cr content reaches a certain value. Therefore, stainless steel in general Cr (chromium) content of at least 10.5%. Stainless steel also contains Ni, Ti, Mn, N, Nb, Mo, Si and other elements.

Send your message to us

Price of 1kg 304 price Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords