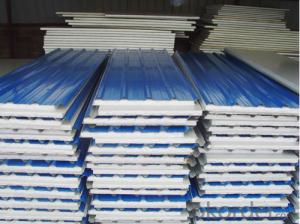

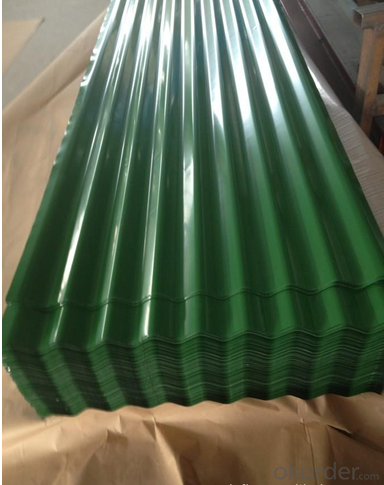

Pre-Painted Galvanized Steel Roofing Sheet PPGI 0.4mm-0.5mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Prepainted galvanized steel coil, PPGI, PPGL, Prepainted galvalume/aluzincsteel, Color Coated Galvalume Steel Coil, Prepainted Galvalume Steel Coils, RAL color, 0.15-1.5mm, SGCC, CGCC, CGLC, DX51D, TDC51D, ASTM A653, CS TYPE, S280GO, S350GD, G550, JIS G3312, EN 10169 JIS G3322, ASTM A755/755M, comercial and structual quality

Specifications of Pre Painted Galvanized Steel Coil:

1) Capacity: More than 20, 000 tons per month for PPGI coil product manufacture

2) Standard: JIS G3302, JIS G3312, ASTM A653M/A924M 1998

3) Grade: SGCC CGCC, DX51D, TDC51D, ASTM A653 CS TYPE, S280GD, S350GD, G550

4) Thickness: 0.15mm-1.5mm

5) Zinc coating weight: Z60-275G/M2, G30-G90

Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

6) Width: 600mm-1250mm, 914mm, 1000mm, 1200mm, 1219mm, 1220mm, 1250mm or according to the customer's request

7) Coil ID: 508mm-610mm

8) Coil Weight: 3-6mt, or according to the customer's request

9) Color: RAL, or customer sample color

RAL9016, RAL9002, RAL5015, RAL5002, RAL3000, RAL3020, RAL3009, RAL6005, RAL8017 etc.

10) Color coating type: PE, PVDF, SMP, HDP, etc.

Regular Polyester, Silicon Modified Polyester, Polyvinylidene Floride, PVDF, Super Low Gloss Polyester

11) Surface protection: PVC film protected according to customer requested

12) Min trial order: 25 tons for 1X20' per delivery

PPGI Manufacture

ThicknessWidth LengthColor Coating type

0.2mm-1.5mm600mm-1250mmAs your requestRALPE, PVDF, SMP, HDP, etc.

Coating Chief Feature

ItemThicknessTypeFeature

Laminated film50μ MPolyethyleneProtecting from scratchs and contamination

(option)

Top coat20μ MPolyester FluorineChemical resistance and formability

Primer coat5μ MPolyesterWorkability, corrosion resistance and adhesion to the primer coating

Chemical treatment1μ MChromateGood adhesion and corrosion resistance

Substrate0.2mm-1.2mmGI. GL, ALGI. GL, AL

Back coat5± 2μ MEpoxyCorrosion resistance and adhesion to the substrate

Characteristics:

20 years outdoor liability approved, Corrosion protection, Long life-time for coated color

APPLICATION:

Exterior decoration of buildings: Roof and wallboards of industrial, commercial, residential and public facilities

Interior decoration of buildings: Wallboards, ceiling boards, partition boards, fireproof doors

Building accessories: Window panels, signboards

Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

World wide customer satisfaction:

More than 50 worldwide customers none-risky experiences approved.

Yogic has been exporting steel coils to more than 50 countries directly. Our long term supply extends to USA, UK, Germany, Italy, Spain, Belgium, France, Poland, Greece, Ukraine, Belarus, Russia, Turkey, Egypt, Saudi Arabia, Iran, Ethiopia, Niger, Brazil, Colombia, Chile, Peru, Australia, New Zealand, etc...

Classified symbol | Yield Point Minimum N/mm2 | Tensile Strength Minimum | Elongation Minimum % | Application | ||||

N/mm2 | Nominal Thickness mm (t) | |||||||

JIS | CNBM | 0.25≤t<0.4< td=""> | 0.4≤t<0.6< td=""> | 0.6≤t<1.0< td=""> | 1.0≤t<1.6< td=""> | |||

G3312 | specification | |||||||

CGCC | CGCC | -205 | -270 | -20 | -21 | -24 | -24 | Commercial |

CGCD | CGCD | --- | 270 | --- | 27 | 31 | 32 | Drawing |

--- | CG340 | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

CGC400 | CG400 | 295 | 400 | 16 | 17 | 18 | 18 | Structural |

CGC440 | CG440 | 335 | 440 | 14 | 15 | 16 | 18 | Structural |

CGC490 | CG490 | 365 | 490 | 12 | 13 | 14 | 16 | Structural |

CGC570 | CG570 | 560 | 570 | --- | --- | --- | --- | Structural |

ASTM Designation | Yield Point Minimum | Tensile Strength Minimum | Elongation Minimum % | Application | Q/BQB 445-2004(China standard) | ASM A653/A653M | JISG 3312 | |

ksi(MPa) | ksi(MPa) | TDC51D+Z | (CS TYPE A+Z) | CGCC | ||||

A653(M)-99 CS TYPE A,B,C | --- | --- | --- | Commercial | TDC52D+Z | CGCD | ||

A653(M)-99 FS | --- | --- | --- | Lock Forming | TS250GD+Z | (G250+Z) | - | |

A653(M)-99 DS | --- | --- | --- | Drawing | TS300GS+Z | (G300+Z) | CGC 400 | |

A653(M)-99 SS Grade33(230) | 33(230) | 45(310) | 20 | Structural | TS350GD+Z | (G350+Z) | CGC490 | |

A653(M)-99 SS Grade37(255) | 37(255) | 52(360) | 18 | Structural | TS550GD+Z | (G550+Z) | CGC570 | |

A653(M)-99 SS Grade40(275) | 40(275) | 55(380) | 16 | Structural | ||||

A653(M)-99 SS Grade50(345) | 50(345) | 65(450) | 12 | Structural | ||||

A653(M)-99 SS Grade80(550) | 80(550) | 82(570) | --- | Structural | ||||

FAQ

1. Is the sample available?

Yes, samples can be sent for test if you need.

2.What's your MOQ?

25MT, it is for one container.

3.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

- Q: I'm currently in an Estimating and Bidding class. I have to estimate two divisions for a multi-million dollar project. The project that I chose is around 6 million dollars and involves constructing a new gas/lighting building. I chose to estimate steel, and my question is, around how much out of the 6 million goes toward just the steel estimate? If it helps, this building is has two floors and is roughly about 100x70 feet. The building not wood construction, but rather steel and brick. How much of that 6 million would go into the steel? I'm not looking for anything exact, just roughly.

- That is a little tough to answer given the details. I will try to answer it as best I can. You can send me a message if you need further help and I can get some more details from you. If it is a 6 million dollar project, that is about $428/sf - (6 million divided by 14,000 sf). $428 is a little bit higher end then say, just a Walmart which is a block and steel box. Assuming you have a concrete slab on the first floor, metal deck on the second floor, with steel beams and open web joists framing, steel columns and steel roof framing with a metal deck roof.... you could be approx 10-15% of the total 6 million. Now, this would include the structural steel, not light gauge steel framing for walls. It sounds like you are looking for structural steel, not metal stud framing. Hopefully this helps, I can check back to this thread later to see if you've had to add any more details.

- Q: What is the difference between black steel pipes and galvanized steel pipes when used for water or gas, and why?

- This Site Might Help You. RE: What are black steel pipes made of ? What is the difference between black steel pipes and galvanized steel pipes when used for water or gas, and why?

- Q: What are the different coil slitting methods used for steel coils?

- Steel coils can be slit into smaller, narrower coils using various methods. These methods serve the purpose of cutting the coils to suit specific applications. 1. The most commonly used method for coil slitting is blade slitting. Circular knives or blades are employed to cut the steel coil into narrower strips. These blades are placed at predetermined intervals and usually attached to a rotating shaft. As the coil passes through the blades, their circular motion slices through the coil, resulting in the desired narrower strips. 2. Another method, known as rotary shear slitting, involves the use of two sets of rotary shear knives to cut the steel coil. These upper and lower sets of knives rotate in opposite directions, creating a scissor-like cutting action. As the coil is fed through the shearing blades, the sharp edges of the knives slice through the coil, producing the desired narrower strips. 3. Sliding shear slitting is yet another method utilized for coil slitting. This method involves a stationary upper knife and a moving lower knife to cut the coil. The lower knife moves back and forth across the coil while the upper knife remains fixed. As the coil passes through the moving knife, it is cut into narrower strips. 4. Crush slitting is a less common method employed for coil slitting. In this method, the steel coil is fed through a set of rollers equipped with blades. Although the blades are not sharp, the pressure exerted by the rollers crushes and fractures the coil, resulting in the creation of the desired narrower strips. 5. Laser slitting is a modern and precise method used for coil slitting. It utilizes a laser beam to cut through the steel coil. The laser beam is directed onto the coil, and its high intensity melts and vaporizes the steel, creating a narrow slit. Laser slitting offers high accuracy and a clean cut, making it suitable for specialized applications. Each of these coil slitting methods possesses its own advantages and limitations. The choice of method depends on factors such as the type of steel, desired strip width, production volume, and required precision. Manufacturers select the most suitable method based on their specific requirements and the properties of the steel coils they are processing.

- Q: How are steel coils used in the production of household goods?

- Steel coils are an essential component in the production of various household goods. These coils are typically made from high-quality steel and are manufactured to specific dimensions and thicknesses to meet the requirements of different products. One of the primary uses of steel coils in household goods production is in the manufacturing of appliances such as refrigerators, washing machines, and dishwashers. The coils are used to create the body and framework of these appliances, providing strength, durability, and stability. Additionally, steel coils are often used in the production of smaller household appliances like toasters, blenders, and coffee makers. Furthermore, steel coils are also used in the production of furniture, particularly in the manufacturing of metal frames for chairs, tables, and cabinets. These coils provide the necessary support and structural integrity to the furniture, ensuring long-lasting durability. Another significant application of steel coils in household goods production is in the production of shelving units and storage solutions. Steel coils can be shaped and formed to create sturdy shelves and racks that can hold heavy items and withstand regular use. These shelves are commonly used in kitchens, garages, and storage rooms to organize and store various household items. In summary, steel coils play a crucial role in the production of household goods. They are used to create the framework, structure, and support for appliances, furniture, and storage solutions. Their strength, durability, and versatility make them an ideal material for manufacturing a wide range of household products that are designed to withstand everyday use.

- Q: What are the different types of steel coil cutting machines?

- In the market, there is a wide range of steel coil cutting machines available, each tailored to meet specific needs and requirements. Some commonly used types include: 1. Slitting Machines: These machines are utilized to cut steel coils into narrower strips. Equipped with multiple circular blades, they are capable of making precise cuts along the length of the coil, enabling the production of narrower coils or strips. 2. Cut-to-Length Machines: Designed to cut steel coils into specific lengths, these machines possess the ability to accurately measure and cut the coil to the desired length, ensuring uniformity and precision. 3. Rotary Shears: Rotary shears are robust cutting machines that can handle thicker and larger steel coils. Utilizing a rotating blade, they are suitable for cutting thicker gauge materials. 4. Multi-Blanking Machines: Intended for cutting steel coils into multiple smaller blanks simultaneously, these machines have the capability to cut the coil into various shapes and sizes. This makes them ideal for producing multiple parts from a single coil. 5. Slit and Cut-to-Length Combination Machines: These machines integrate the functionalities of both slitting and cut-to-length machines, enabling the cutting of narrow strips and lengths in a single process. They offer versatility and efficiency, saving time and increasing productivity. Each type of steel coil cutting machine possesses distinct advantages and is suitable for specific applications. The choice of machine depends on factors such as coil thickness, desired strip width, required length accuracy, and production volume.

- Q: (I'm not sure if steel is in fact a mineral)But I want to know if .. Last say topaz is stronger/harder then steel

- Sandpaper , quartz will wear a hole in alloy steel. Just rub it. The steel that is.

- Q: What are the common coil packaging methods?

- Common coil packaging methods include shrink wrapping, strapping, banding, and stretch wrapping. Shrink wrapping involves using a heat shrink film to tightly encase the coil, while strapping and banding utilize metal or plastic bands to secure the coil in place. Stretch wrapping involves wrapping the coil with a stretchable film to provide stability and protection. These methods are commonly used in industries such as steel, wire, and cable manufacturing.

- Q: How do steel coil manufacturers ensure fair pricing?

- Steel coil manufacturers ensure fair pricing through various measures. Firstly, they conduct thorough market research to understand the current industry trends, demand-supply dynamics, and competitor pricing. This helps them determine a competitive yet fair pricing strategy that aligns with market standards. Secondly, steel coil manufacturers consider the cost of raw materials, production, and operational expenses to determine a reasonable base price. They also factor in economies of scale, as larger production volumes can lead to lower costs per unit. Additionally, steel coil manufacturers often establish long-term partnerships with suppliers to ensure a stable and consistent supply of raw materials at fair prices. This allows them to maintain a reasonable cost structure and minimize price fluctuations. Furthermore, these manufacturers strive for transparency in pricing by providing detailed quotations that break down the cost components. This helps customers understand the factors contributing to the final price and ensures fairness in the pricing process. To enhance fairness, steel coil manufacturers also consider the specific requirements of their customers. They may offer customized pricing based on factors such as order volume, delivery timelines, and value-added services. This approach ensures that each customer receives a price that is commensurate with their unique needs and requirements. Overall, steel coil manufacturers ensure fair pricing by conducting market research, considering cost factors, maintaining transparent pricing practices, and offering customized pricing options. By doing so, they aim to create a fair and mutually beneficial pricing environment for both themselves and their customers.

- Q: okay i got some questions of the steel plow.1st - who inveneted it? where and when?2nd - how did it work? what is it used for? what is it made of? how is it produced?okay guys thank you very much. remember best answer gets best answer 10 points!

- If you're willing to substitute the word iron for steel (steel came a good bit later in history), the Girard plow from the 1300's in Belgium would be the first example known. It's named after the guy who invented it (Girard). How did it work? Like any other plow! You drag it along and it makes a trench of sorts in the ground! It was used for agricultural purposes. As for how it was produced, you need to look up the history of the Iron Age to understand how they started to use iron back in about 1200BC to make tools.

- Q: What are the different methods of edge trimming for steel coils?

- There are several methods of edge trimming for steel coils, depending on the specific requirements and application. Some of the common methods include: 1. Slitting: This is one of the most common methods used to trim the edges of steel coils. It involves passing the coil through a set of circular knives that cut the edges into narrower strips. Slitting can be done in-line during the manufacturing process or as a separate operation. 2. Shearing: Shearing is another popular method used for edge trimming. It involves using a set of blades to cut the edges of the coil in a straight line. Shearing is often used when precise and clean cuts are required, and it can be done manually or with the help of automated machinery. 3. Laser cutting: Laser cutting is a more advanced method that uses a high-powered laser to trim the edges of steel coils. This method provides precise and smooth cuts, and it is often used when high accuracy and quality are essential. Laser cutting can be incorporated into the production line or performed as a standalone process. 4. Grinding: Grinding is a method that involves using abrasive wheels or belts to remove material from the edges of steel coils. It is commonly used to remove burrs, rough edges, or surface imperfections. Grinding can be done manually or with the help of automated machines, depending on the scale and complexity of the trimming process. 5. Waterjet cutting: Waterjet cutting is a method that utilizes a high-pressure jet of water mixed with abrasive particles to trim the edges of steel coils. This method is known for its versatility and ability to cut through a wide range of materials and thicknesses. Waterjet cutting is typically used when complex shapes or intricate designs need to be achieved. Overall, the choice of edge trimming method for steel coils depends on factors such as the desired accuracy, speed, complexity of the edges, and the specific requirements of the application. Different methods offer varying levels of precision, efficiency, and cost-effectiveness, allowing manufacturers to select the most suitable technique for their specific needs.

Send your message to us

Pre-Painted Galvanized Steel Roofing Sheet PPGI 0.4mm-0.5mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords