0.4mm-0.5mm Pre-Painted Galvanized Steel Roofing Sheet PPGI

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

0.4mm/0.45mm/0.47mm/0.5mm Pre-Painted galvanized Steel Roofing Sheet PPGI

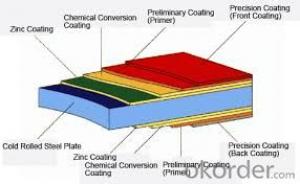

Painting: Polyester(PE) PVDF

Standard: ASTM, JIS,AISI, GB

Grade: SGCC.SPCC.DC51D,DC52D,DC53D

thickness: 0.2mm---1.0mm

Width: 914mm,1000mm, 1200mm, 1250mm, 1500mm or as your request

Zinc coating: 40-250g/m2

Color: Ral code or as the client request

Packing: wooden with the waterproof paper

Delivery: 4 weeks

MOQ: 5tons or negotiable

Applications

1) Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker

2) Exterior applications such as: Wall cladding, facades, roofs and canopies, tunnels, column covers or renovations

3) Interior applications such as: Wall cladding, ceilings, bathrooms, kitchens and balconies

Brand Name | CNBM |

Product Name | PPGI / PPGL (PCM) |

Thickness of Base Metal | 0.2~0.8mm |

Painting material | Polyester(PE) PVDF epoxy |

Painting Thickness | 7~30μm |

Surface Protection | PE protective film |

Color | Ral code or as the client request |

Surface Treatment | Degreasing and chemical treatment |

Gloss | 5-105% |

Coating Hardness (pencil resistance) | ≥H |

Flexibility (T-bend) | ≤2T |

MEK resistance | More than 100 |

Supplying Status | Sheet: Width≤2000mm,Length≤5000mm |

Coil: Width≤2000mm,N.W≤5T,Inner Diameter: φ408mm φ505 φ508 | |

Application | Home appliance: Refrigerator shutter & side panels, Washer, Freezers, Air conditions, Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods Computer Panels , DVD/DVB panels, TV back panel etc. |

FAQ

1.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

2.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

3. Is the sample available?

Yes, samples can be sent for test if you need.

4. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: i have a white spot on my stainless steel stove, its on the part behind the burners where the oven controls are, does anyone know what it may be and how to remove it. i have tried soap and water and stainless steel cleaner but neither worked. thanks!

- Barkeeper's Friend is the bomb for a metal and fiberglass cleaner, if it can be removed, it will remove it. I have no clue what it is thats on there.

- Q: How do steel coils contribute to the HVAC industry?

- The HVAC industry relies heavily on steel coils, which play a critical role in the functioning and efficiency of HVAC systems. These coils, often made from high-quality steel like stainless steel or galvanized steel, ensure durability and resist corrosion. One way steel coils contribute to the HVAC industry is by facilitating heat transfer. HVAC systems use coils to transfer heat between the air and a refrigerant. For instance, in air conditioning units, the evaporator coil absorbs heat from the indoor air, while the condenser coil releases heat to the outside air. The steel coils in these units provide a large surface area for efficient heat exchange, allowing for effective cooling or heating of the air. Furthermore, steel coils contribute to the energy efficiency of HVAC systems. By maximizing heat transfer, these coils enable HVAC systems to operate at optimal performance levels while consuming less energy. This not only reduces energy costs for users but also makes HVAC systems more environmentally friendly by minimizing energy consumption and greenhouse gas emissions. Steel coils in HVAC systems also play a role in maintaining indoor air quality. As air passes over the coils, impurities like dust, dirt, or mold can accumulate on the coil's surface. Regular maintenance and cleaning of the coils are essential to prevent the buildup of contaminants that could negatively impact air quality. Properly maintained steel coils ensure clean and healthy indoor air, which is particularly important for commercial buildings, hospitals, and other spaces where air quality is crucial. Additionally, steel coils provide durability and longevity to HVAC systems. Steel is a strong and resilient material that can withstand high temperatures, pressure, and environmental stress. By using steel coils, HVAC systems can operate reliably and efficiently for extended periods, reducing the need for frequent repairs or replacements. Overall, steel coils are indispensable to the HVAC industry. They enable efficient heat transfer, enhance energy efficiency, improve indoor air quality, and provide durability to HVAC systems. Without steel coils, HVAC systems would significantly lose their performance and effectiveness, highlighting the vital role of steel coils in the HVAC industry.

- Q: What are the dimensions of steel coils used in the railway equipment industry?

- The railway equipment industry utilizes steel coils with dimensions that can vary according to the specific application and requirements. However, there are commonly observed dimensions for these steel coils, typically ranging from 3 to 5 feet in width and 10 to 15 feet in length. Likewise, the thickness of the steel coils exhibits variation, spanning from 0.01 to 0.5 inches. It should be noted that these dimensions are not set in stone and may fluctuate based on the specific demands of the railway equipment industry, such as the type of equipment being produced or the distinct purpose of the steel coils.

- Q: I have a set of Ben Hogan Apex Plus Forged Irons, how can i figure out if the shafts are steel or graphite?

- Hold one club in each hand and hit them together like swords fighting, putting the impact point about midway down each shaft, and listen to the sound. If it's more of a clank sound, it's steel, and more of a click sound, it's graphite.

- Q: What are the main characteristics of steel coils?

- The main characteristics of steel coils include their high strength and durability, excellent corrosion resistance, and ability to be easily formed and shaped. They are typically made from carbon steel and come in various widths, thicknesses, and lengths. Steel coils are commonly used in a wide range of industries such as construction, automotive, and manufacturing for applications such as roofing, structural components, and electrical appliances.

- Q: Can steel coils be used in architectural applications?

- Yes, steel coils can be used in architectural applications. Steel coils are versatile and can be processed into various shapes and forms to meet the unique design requirements of architectural projects. They can be used in the construction of buildings, bridges, and other structures, as well as in the fabrication of architectural elements such as roofing, cladding, and facades. Steel coils offer several advantages in architectural applications. They are highly durable, strong, and resistant to corrosion, making them suitable for long-lasting and low-maintenance structures. Steel coils can also be customized in terms of thickness, width, and surface finish, allowing architects to achieve their desired aesthetic and functional goals. In addition, steel coils are known for their structural stability and load-bearing capacity, which are crucial factors in architectural designs. Their high strength-to-weight ratio makes them an ideal choice for creating large and open interior spaces, as well as for supporting heavy loads in multi-story buildings. Furthermore, steel coils can be easily fabricated and installed, saving time and labor costs during construction. They can be efficiently formed, cut, and welded to create complex shapes or architectural details. Moreover, steel coils can be pre-fabricated off-site, ensuring precision and quality control, and then assembled on-site, reducing construction time and minimizing disruptions to the surrounding environment. Overall, steel coils offer architects and designers a wide range of possibilities in architectural applications. Whether it is for structural support, aesthetic appeal, or functional requirements, steel coils provide a reliable and versatile material option that can meet the demands of modern architectural projects.

- Q: What are the typical dimensions of a steel coil?

- The typical dimensions of a steel coil can vary depending on its purpose and industry standards. However, common dimensions for steel coils include a width ranging from 600mm to 2000mm, a coil diameter of around 1000mm to 2000mm, and a weight capacity ranging from a few tons to several dozen tons.

- Q: Having a new kitchen and would like to know the pros and cons of stainless steel as opposed to white appliances. I can only think of finger marks on the SS, which I believe are difficult to remove. Anyone had both that they could advise please?

- I have Stainless Steel and YES it shows finger prints etc, Since there are no children around it's easier to keep clean, but one word of caution when using commercial SS cleaners, if the spray gets onto the floor it's almost impossible to get off and makes it slippery as ice. I'd use newspaper before using a SS cleaner,, I've had both and would opt for WHITE in any case. So easy to maintain, Now, they do make a Faux SS, which is very nice., and don't show any markings at all, our Son has one and with 3 kids in the house constantly using the Fridge it's been great, you might want to look into that..

- Q: Cooling bed generally a part of the steel rolling mills

- Another type of cooling bed is used for square stock. It consists of several beams with angles cut upward from the bottom. The beams move in alternating fashion so that the square beam is lifted and sat into the next 'tooth'. The angle is cut so that the beam rotates as it is set down. This keeps the stock straight while it cools.

- Q: What are the common coil slitting equipment used in the industry?

- The common coil slitting equipment used in the industry includes slitter rewinders, slitter cutters, and slitter knives. These machines are designed to accurately cut and rewind coils of various materials, such as metal, paper, and plastic, into narrower strips or coils of desired widths.

Send your message to us

0.4mm-0.5mm Pre-Painted Galvanized Steel Roofing Sheet PPGI

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords