Galvanized Color Coated Plate Roofing Sheet PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Galvanized Color Coated Plate Roofing Sheet PPGI

Details of Galvanized Color Coated Plate Roofing Sheet PPGI

Grade | DX51D, SGCC, CGCC |

Thickness | 0.15mm-1.5mm |

Width | 600mm-1500mm(914/1219/1250 are available) |

Standard | JIS G3312, ASTM,GB/T1275 |

Certificate | ISO9001.ISO14001.OHSAS18001 |

Length | As per requests |

Zinc Coating | 40g-275g/m2 |

Lacquer Coated | 20-25 microns/5-15 microns |

Coil ID | 508mm/610mm |

Coil Weight | normally 3-10mt or as your requirement |

Supply ability | 200,000Mt/year (MOQ:25Mt) |

Color | RAL No. |

Price terms | FOB,CFR,CIF |

Payment terms | L/C,T/T |

Deliver time | 30days after received deposit or L/C |

Packing | Standard exporting package |

steel strip Water proof paper, metal covers, | |

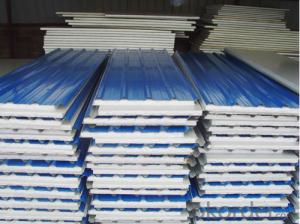

Application | Corrugated roofing,outside building, |

boating building,car producing | |

household appliance | |

Main market | Southeast Asia , the EU, Russia, Ukraine , Latin America and other countries and Regions |

Specification of Galvanized Color Coated Plate Roofing Sheet PPGI

Thickness | Width | Length of plate | Inner diameter of coil |

0.18-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Coated Mass: | |||

Available Coated Mass(g/m^2) | Base plate | Available Coated Mass(g/m^2) | |

60,80, 100, 120, 160, 180 | Galvanized Steel | 60,80, 100, 120, 160, 180 | |

50, 70, 150 | Galvalume Steel | 50, 70, 150 |

Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 20±5microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

Painting structure | Top surface | Bottom surface |

|

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coatin | Primer coating + Finish back coating | 2/2 | |

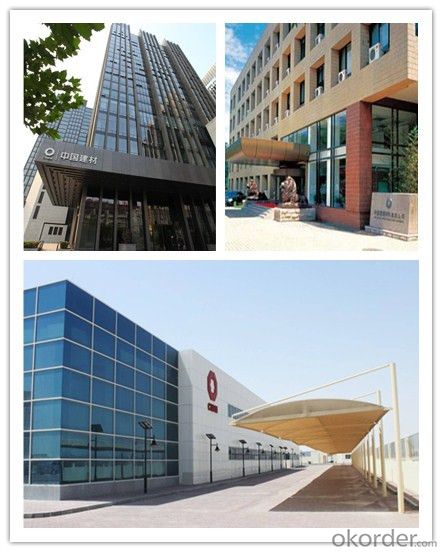

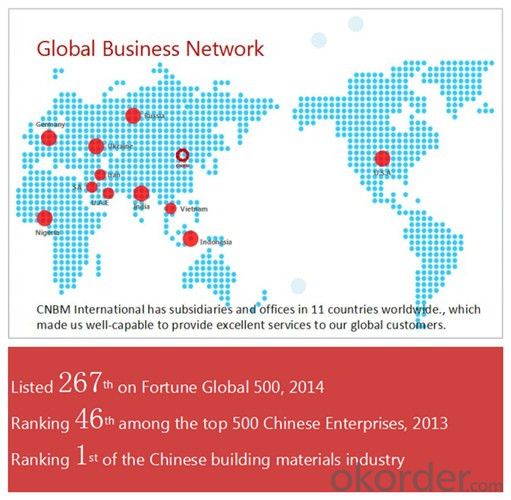

CNBM Introduction of Galvanized Color Coated Plate Roofing Sheet PPGI

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Galvanized Color Coated Plate Roofing Sheet PPGI

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

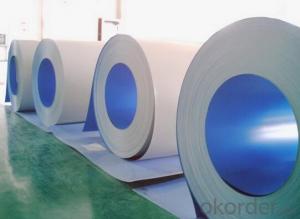

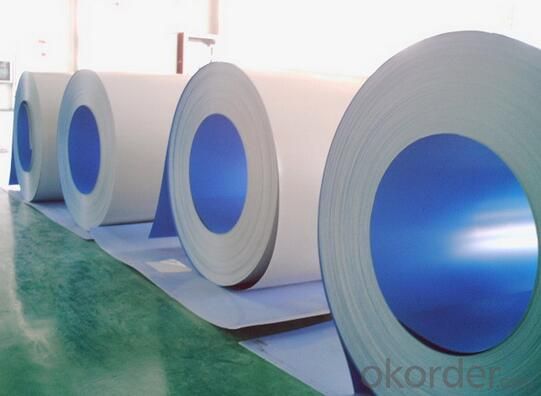

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the main characteristics of high-speed steel?

- High-speed steel is known for its exceptional hardness, toughness, and heat resistance. It can maintain its hardness even at high temperatures, making it ideal for cutting tools and machining applications. Additionally, high-speed steel has excellent wear resistance, allowing it to withstand heavy usage and prolong tool life. It also has good machinability and can be easily shaped into various cutting tools.

- Q: What is the purpose of annealing in special steel production?

- The aim of annealing in the production of special steel is to enhance the mechanical characteristics and overall quality of the steel. Annealing involves subjecting the steel to a particular temperature and gradually cooling it, typically in a controlled setting. This procedure aids in relieving any internal stresses or strains that might have developed during previous manufacturing processes like rolling or forging. During the annealing process, the microstructure of the steel goes through changes, resulting in a more refined and uniform material. The process allows for the redistribution of atoms, thereby eliminating defects, improving grain structure, and enhancing the steel's toughness, ductility, and machinability. Furthermore, annealing helps in reducing the hardness of the steel, rendering it easier to work with and shape. It also enhances the steel's resistance to cracking and increases its ability to withstand corrosion and other environmental factors. In certain special steel alloys, annealing can also be employed to achieve desired physical properties such as increased hardness or improved magnetic characteristics. Ultimately, the objective of annealing in the production of special steel is to optimize the steel's properties and ensure it meets the specific requirements of its intended application, be it in industries such as automotive, aerospace, or manufacturing.

- Q: How does special steel contribute to the waste management industry?

- Special steel plays a crucial role in the waste management industry by providing durable and corrosion-resistant materials for various applications. It is used in the fabrication of waste containers, compactors, and shredders, ensuring their longevity and ability to withstand harsh environments. Additionally, special steel is utilized in incinerators and waste-to-energy plants, where its high heat resistance helps optimize the combustion process. Overall, special steel contributes to the waste management industry by enhancing the efficiency, durability, and sustainability of its equipment and infrastructure.

- Q: Are there any international standards for special steel?

- Yes, there are international standards for special steel. The most widely recognized and accepted international standards for special steel are set by the International Organization for Standardization (ISO). ISO develops and publishes a range of standards that cover various aspects of special steel, including composition, properties, testing methods, and quality requirements. These standards ensure that special steel produced by different manufacturers from different countries meet the same minimum quality and performance criteria. In addition to ISO, there are also other organizations and standards bodies that have their own specific standards for special steel, such as the American Society for Testing and Materials (ASTM) and the European Committee for Iron and Steel Standardization (ECISS). These international standards provide a common framework for the production, trade, and use of special steel across different countries and industries, promoting consistency, reliability, and quality assurance.

- Q: What are the specific requirements for special steel used in the marine propeller industry?

- The special steel used in the marine propeller industry must meet specific requirements to ensure optimal performance and durability in harsh marine environments. Some of the key requirements include: 1. Corrosion Resistance: Marine propellers are constantly exposed to saltwater, which can cause corrosion. Therefore, special steel used in the marine propeller industry must have high resistance to corrosion, preventing the formation of rust and maintaining the propeller's integrity over time. 2. Strength and Toughness: Marine propellers are subjected to high mechanical stresses and impacts, especially in rough sea conditions. The special steel used must possess high strength and toughness to withstand these forces without deformation or failure. 3. Fatigue Resistance: Propellers experience cyclic loading due to rotational forces, which can lead to fatigue failure over time. The special steel should have excellent fatigue resistance to withstand millions of load cycles without developing cracks or fractures. 4. Weldability: Propellers are often manufactured in segments and then welded together. The special steel used must be easily weldable, ensuring strong and reliable joints that can withstand the propeller's operational stresses. 5. Heat Resistance: Propellers generate significant heat due to friction and propulsion forces. The special steel should have good heat resistance to prevent deformation or loss of mechanical properties at elevated temperatures. 6. Machinability: Special steel used in the marine propeller industry should be readily machinable to allow for precise shaping and finishing of complex propeller blade designs. 7. Non-Magnetic Properties: Many modern ships utilize magnetic navigation systems and sensors. Therefore, the special steel used in propellers should have low magnetic permeability to minimize interference with these systems. Meeting these specific requirements ensures that the special steel used in the marine propeller industry can withstand the challenging conditions of seawater, provide efficient propulsion, and maintain its structural integrity throughout the propeller's lifespan.

- Q: What are the different methods of surface tumbling for special steel?

- There are several methods of surface tumbling for special steel, including barrel tumbling, vibratory tumbling, and centrifugal tumbling. Barrel tumbling involves placing the steel parts in a rotating barrel with abrasive media, which helps to remove burrs, sharp edges, and surface imperfections. Vibratory tumbling uses a vibrating machine with abrasive media to achieve similar results. Centrifugal tumbling, on the other hand, involves placing the steel parts in a rotating drum and using centrifugal force to propel abrasive media against the surfaces, resulting in a smooth and polished finish.

- Q: How does special steel contribute to sustainability?

- Special steel contributes to sustainability in several ways. Firstly, it is highly durable and has a longer lifespan compared to traditional steel, reducing the need for frequent replacements and minimizing waste. Additionally, special steel can be recycled and reused multiple times without losing its properties, reducing the demand for new raw materials and energy consumption in the production process. Furthermore, special steel offers superior strength and lightweight characteristics, enabling the development of more fuel-efficient vehicles and structures, thus reducing carbon emissions. Overall, special steel's durability, recyclability, and energy efficiency make it a key material in promoting sustainable practices in various industries.

- Q: What are the main applications of special steel in the shipbuilding industry?

- Special steel is widely used in the shipbuilding industry for various applications. Some of the main applications include the construction of ship hulls, decks, and superstructures, as well as the fabrication of critical components such as propeller shafts, rudders, and marine engines. Special steel's high strength, corrosion resistance, and durability make it ideal for withstanding the harsh marine environment and ensuring the safety and reliability of ships. Additionally, special steel is also utilized in the production of offshore structures, such as oil rigs and offshore wind turbines, due to its ability to withstand extreme weather conditions and corrosive elements present in offshore environments.

- Q: What are the applications of special steel in the manufacturing supply chain?

- Special steel has various applications in the manufacturing supply chain. It is commonly used in industries such as automotive, aerospace, energy, and construction. Special steel's unique properties, including high strength, durability, and resistance to corrosion and wear, make it ideal for manufacturing components and parts that require exceptional performance under demanding conditions. These applications can range from manufacturing engine components, structural parts, tools, and machinery, to oil and gas pipelines, power generation equipment, and building infrastructure. Special steel plays a crucial role in enhancing the overall efficiency, reliability, and safety of the manufacturing supply chain.

- Q: How does special steel contribute to the manufacturing of cutting blades for industrial machines?

- Special steel plays a crucial role in the manufacturing of cutting blades for industrial machines by offering enhanced strength, durability, and wear resistance. The unique properties of special steel, such as high hardness, toughness, and corrosion resistance, allow cutting blades to withstand the demands of heavy-duty applications. This enables them to cut through various materials, such as metal or concrete, with precision and efficiency, resulting in improved productivity and longevity of industrial machines.

Send your message to us

Galvanized Color Coated Plate Roofing Sheet PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords