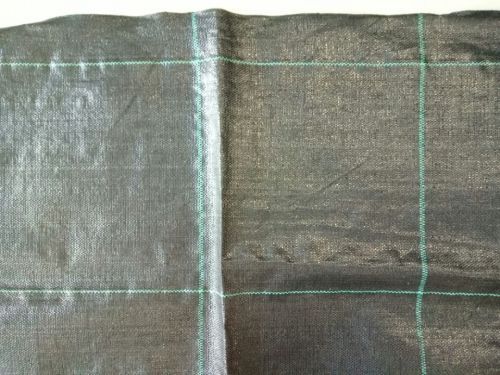

16 Oz Non Woven Geotextile PP/PE Woven Fabric Weed Barrier Fabric Silt Fence

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

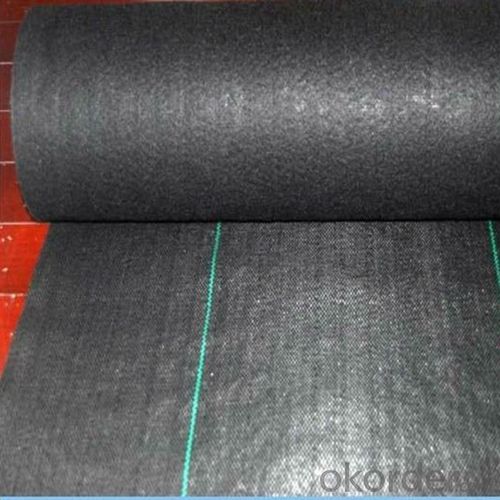

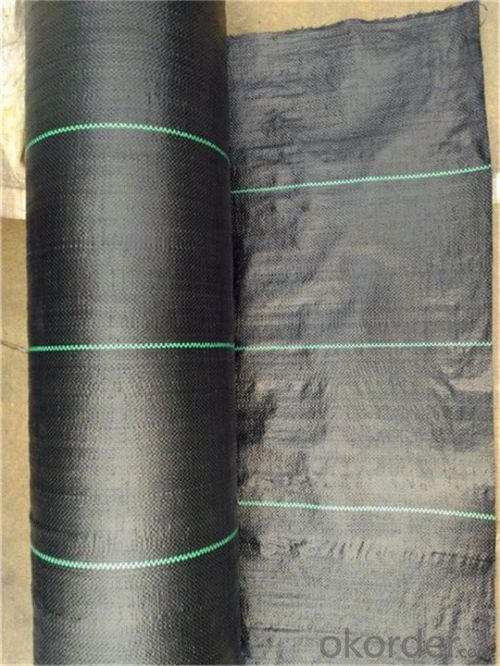

1.Woven Fabric Description:

The woven fabric is a kind of vertical and horizontal weaving plastic woven cloth. It has good quality of permeability,water seepage and prevention and control of weeds. Widely used in gardening and agriculture.

2.Woven Fabric Functions and Features:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

8)Ideal for use in landscaped beds,under decks and walkways

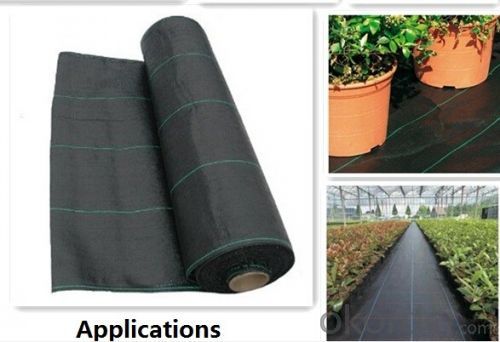

3. Woven Fabric Usage:

1.Prevent leakage disposal in landfill or waste water or waste dregs disposing field.

2.River bank ,lake dam ,mine remainings ,resevoir ,tunnel ,liquid storage pool(pit ,mine)

3.Preventing leakage in subway ,basement ,tunnel ,hole .

4.Anti-salt leakage in roadbed and other ground sill.

5.The plane direction laying of dam ,the vertical direction laying for ground sill.used in the construction fence and waste material field.

6.Used in ground sill of road ,highway ,railway and waterproof layer of welling clay and wet collapsed loess.

7.Preventing leakage on rooftop.

4. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geotextiles help in preventing the loss of aggregate in parking lots?

- Geotextiles help in preventing the loss of aggregate in parking lots by acting as a barrier between the aggregate and the underlying soil. This prevents the aggregate from sinking into the soil and being displaced by the weight of vehicles or erosion caused by water runoff. The geotextile material provides stability and reinforcement to the aggregate, helping to maintain its integrity and prolong the lifespan of the parking lot.

- Q: What are the different geotextile testing methods?

- There are several geotextile testing methods that are commonly used to evaluate the performance and quality of geotextile materials. Some of these methods include tensile strength testing, puncture resistance testing, tear resistance testing, bursting strength testing, and water permeability testing. These tests help determine the suitability and durability of geotextiles for various applications such as soil stabilization, filtration, and erosion control.

- Q: Are geotextiles resistant to chemical leaching?

- Yes, geotextiles are generally resistant to chemical leaching. They are designed to have low permeability and are made from materials that can withstand exposure to various chemicals without significant degradation or leaching. However, the level of resistance may vary depending on the specific type and quality of geotextile used.

- Q: Are geotextiles resistant to earthquakes?

- No, geotextiles are not inherently resistant to earthquakes. While geotextiles can provide benefits in terms of soil stabilization and erosion control, they do not have the ability to withstand seismic activity on their own. Additional engineering measures and materials are required to ensure structures are earthquake resistant.

- Q: How are geotextiles used in construction?

- Geotextiles are used in construction to provide reinforcement, filtration, separation, and drainage functions in various applications such as road construction, erosion control, retaining walls, landfills, and drainage systems. They act as a barrier, preventing soil erosion, improving soil stability, and increasing the overall durability and performance of the construction project.

- Q: Geotextile 500 grams is what it means

- 500g per square meter of quality, I professional production geotextile geomembrane, wish smooth

- Q: Geotextile production process

- 1, add polypropylene particles; 2, extrusion continuous fiber filament. Re-stretching and contraction, the fibers cut into short fiber; 3, the fiber is placed in the machine leveling; 4, continue to polymer film. The film is cut into filaments; 5, after stretching again, the filament is wound on the reel. 6, through a variety of independent research and development of the production process, the fiber for acupuncture, followed by thermal bonding. 6, through a variety of independent research and development of the production process, the fiber for acupuncture, followed by thermal bonding. Use this production process to create a geotextile with ultimate strength

- Q: Geotextile exports Nordic need certification

- Production standards geotextile, geomembrane, composite geomembrane.

- Q: What are the different types of geotextiles?

- There are several types of geotextiles, including woven geotextiles, non-woven geotextiles, and knitted geotextiles. Each type has its own unique properties and characteristics that make them suitable for various applications in civil engineering, construction, and environmental projects.

- Q: What are the specifications for geotextiles in wastewater treatment projects?

- The specifications for geotextiles in wastewater treatment projects typically involve factors such as the material type, weight, thickness, permeability, and strength. These geotextiles are commonly required to have high tensile strength, puncture resistance, and durability to withstand the harsh conditions of wastewater treatment facilities. Additionally, they should have a specific permeability to allow for proper filtration and drainage of water while preventing the passage of fine particles.

Send your message to us

16 Oz Non Woven Geotextile PP/PE Woven Fabric Weed Barrier Fabric Silt Fence

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords