PP/PE waterproof materials for bathroom and toilet floor waterproofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 30000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP& PE compound membrane waterproof material for walls is made by multiple-ply different materials, especially its aging and weathering resistance layer enables the

membrane possess more longer effective age. It can bond with many kinds of adhesions,

firm and secure. In case of cement-base, cementations agent can be used,

the cementations agent can easily enter into the non-woven felt layer, forms a

well-combination with cement after solidification, permanent durability.

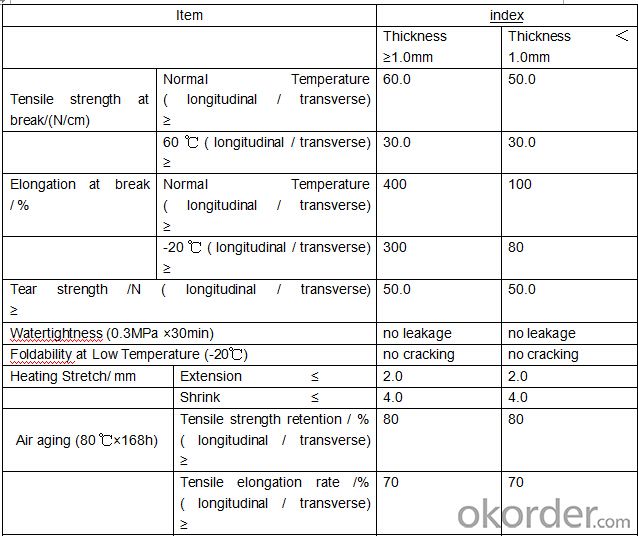

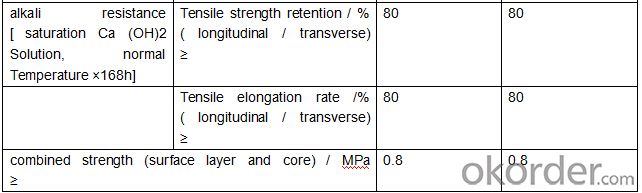

Data Sheet

Characteristic:

1. Non-toxic, no pollution, environmental protecting product.

2. Can be used for many different surfaces, especially for cement basement.

3. Tough, impermeable, multi-layered sheet;

4. High tension strength, good cold flexibility.

Application:

Products used in roofing, basement, restroom, water conservation, warehouse to protect structure from water infiltration.

- Q: Can a waterproofing membrane be used in bathrooms?

- Yes, a waterproofing membrane can be used in bathrooms. In fact, it is highly recommended to use a waterproofing membrane in bathrooms to prevent water damage and leakage. The membrane is typically applied on the walls and floors, creating a barrier that prevents water from seeping through and causing structural damage or mold growth. This is especially important in areas such as showers and around bathtubs where water exposure is high. Waterproofing membranes are designed to withstand moisture and provide long-lasting protection, ensuring the integrity of the bathroom and extending its lifespan.

- Q: Are waterproofing membranes resistant to high-pressure water jets?

- Yes, waterproofing membranes are designed to be resistant to high-pressure water jets. These membranes are specifically engineered to withstand the force and intensity of high-pressure water, ensuring effective protection against water infiltration.

- Q: Can a waterproofing membrane be used in conjunction with a drainage system?

- Using a waterproofing membrane alongside a drainage system is indeed a viable option. In fact, it is frequently advised to employ both simultaneously to achieve optimal waterproofing and drainage results in spaces like basements, roofs, and foundations. The waterproofing membrane serves as a shield against water infiltration, while the drainage system effectively eliminates any surplus water build-up. Through the integration of these two systems, a comprehensive solution is guaranteed to safeguard the structure against potential water-related harm.

- Q: Can a waterproofing membrane be used for tunnels or subway systems?

- Tunnels and subway systems frequently encounter water infiltration as a result of the soil conditions or groundwater levels in their vicinity. To counteract this issue, a waterproofing membrane is commonly employed. This membrane serves as a protective shield, effectively obstructing water from permeating into the tunnels or subway systems. Its installation is typically carried out on the outer surfaces of the tunnel walls and roof, establishing an impervious seal. By doing so, it aids in the prevention of corrosion, decay, and harm to the structural components of the tunnels, guaranteeing the durability and safety of these subterranean infrastructures.

- Q: Are waterproofing membranes resistant to water vapor transmission?

- Yes, waterproofing membranes are resistant to water vapor transmission. These membranes are designed to create a barrier that prevents water from penetrating through them. They are typically made from materials that are impermeable to water, such as rubber, plastic, or bitumen. This means that they effectively block the passage of liquid water, preventing it from seeping into the underlying structure. However, it is important to note that while waterproofing membranes can effectively resist water vapor transmission, they may not completely eliminate it. Some amount of water vapor may still pass through the membrane, but it is significantly reduced compared to other materials that are not designed for waterproofing purposes.

- Q: Can a waterproofing membrane be applied to roofing systems?

- Yes, a waterproofing membrane can be applied to roofing systems. It is a common practice to install a waterproofing membrane on flat or low-slope roofs to provide an additional layer of protection against water infiltration. This membrane helps to prevent leaks and extends the lifespan of the roofing system.

- Q: Are there any specific tools or equipment required for installing a waterproofing membrane?

- Indeed, specific tools and equipment are indispensable when it comes to the installation of a waterproofing membrane. Some of the imperative tools and equipment that one must possess include: 1. Protective gear: To safeguard oneself from any detrimental chemicals or fumes, it is crucial to wear protective gear like gloves, goggles, and a face mask. 2. Cleaning equipment: Prior to the installation of the membrane, it is essential to have a clean and debris-free surface. Hence, one may require a broom, vacuum cleaner, or pressure washer to ensure thorough cleaning. 3. Waterproofing membrane: The appropriate type of membrane is contingent upon the project's requisites. It is vital to possess the right membrane material and sufficient coverage for a proper seal. 4. Primer: In certain cases, the utilization of a primer may be warranted to enhance adhesion between the surface and the membrane. The choice of primer is contingent upon the surface material and type of membrane being utilized. 5. Application tools: These tools are instrumental in the process of applying the membrane onto the surface. Brushes, rollers, or sprayers are some common application tools. The selection of tools is dependent on the type of membrane and the scale of the project. 6. Seam tape: If the waterproofing membrane necessitates seams, the presence of seam tape is vital to ensure an airtight seal at the joints. The tape must be compatible with the membrane material. 7. Adhesive or adhesive tape: Certain waterproofing membranes demand the utilization of adhesive for bonding them to the surface. Alternatively, adhesive tape can be employed for self-adhesive membranes. 8. Cutting tools: Based on the shape and size of the area to be waterproofed, one may require cutting tools such as utility knives or scissors to trim the membrane to the desired dimensions and shape. 9. Caulking gun: A caulking gun is an imperative tool for applying sealant or caulk to fill any gaps or cracks in the surface before the membrane installation. 10. Drying equipment: Following the installation of the membrane, a certain amount of time may be required for it to dry or cure. Depending on the specific membrane and environmental conditions, fans or dehumidifiers may be necessary to expedite the drying process. It is of utmost importance to refer to the manufacturer's guidelines or seek professional advice to ensure that all the necessary tools and equipment are available for a successful installation of the waterproofing membrane.

- Q: Can a waterproofing membrane be used on terraces or patios?

- Yes, a waterproofing membrane can be used on terraces or patios to prevent water penetration and protect the underlying structure from moisture damage.

- Q: Are waterproofing membranes resistant to saltwater corrosion?

- Yes, waterproofing membranes are generally resistant to saltwater corrosion. They are designed to withstand harsh environmental conditions, including exposure to saltwater, without deteriorating or being affected by corrosion.

- Q: Can waterproofing membranes be used on concrete block walls?

- Concrete block walls can indeed benefit from the use of waterproofing membranes. It is actually quite common and highly advised to employ such membranes on concrete block walls in order to ward off water infiltration and potential moisture-related harm. These membranes are specifically engineered to establish a barrier against water and can be effectively applied to either the exterior or interior surface of the concrete block walls. In doing so, they furnish an added layer of safeguarding, thereby preventing moisture from penetrating the walls and causing issues such as the growth of mold, efflorescence, and the deterioration of the concrete blocks themselves. By opting for the utilization of waterproofing membranes, you can effectively ensure the long-lasting resilience and durability of your concrete block walls.

Send your message to us

PP/PE waterproof materials for bathroom and toilet floor waterproofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 30000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords