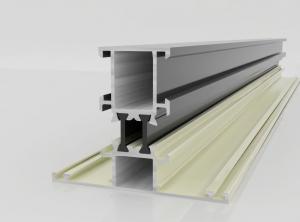

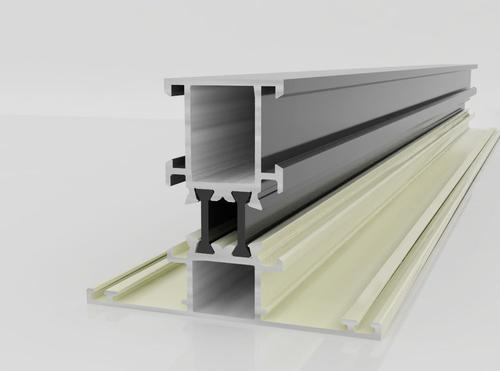

Customized Colorful Powder Coating Aluminum Door Profile AA6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Powder Coating Aluminum door profile of - AA6060

1) Material : 6063 6061 6060 and different aluminium alloy

2) Alloy Temper: T4 T5 T6 or other special status as per customer's needing.

3) Optional Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrophoretic sliver, electrophoretic champagne, electrophoretic golden,

electrophoretic titanium, machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4) Annual capacity : 120000TON

5) Quality : China Nation Standard GB/T 5237 2004 (advanced class)

6) Application: can be widely used for aluminium window, door, curtain wall, hand railing ,

normal aluminium profiles, decoration and industrial aluminium profiles.

7) Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

- Q: You know, aluminum radiator, why should aluminum do?

- The biggest difference of aluminum radiator is that it has good corrosion resistance. Is due to the use of aluminum, it has the characteristics of corrosion resistance, because after aluminum in contact with oxygen, the aluminum surface to form a layer of oxide film, this layer of film to corrosion effect on the corrosion of an object. So, it's very good corrosion resistance.

- Q: Can aluminum profiles be an alternative to steel or other materials?

- Many applications can consider aluminum profiles as a viable alternative to steel or other materials. Aluminum profiles possess several advantages over steel, including their lightweight nature, corrosion resistance, and durability. The low weight of aluminum profiles is a key benefit. Aluminum is approximately one-third the weight of steel, making it ideal for weight reduction purposes. Its lightweight property also makes it easier to handle, transport, and install, which ultimately reduces costs and labor requirements. Furthermore, aluminum profiles exhibit excellent corrosion resistance, especially when compared to steel. When exposed to air, aluminum naturally forms a protective oxide layer that prevents further oxidation and corrosion. This makes aluminum profiles suitable for industries such as construction, automotive, aerospace, and marine, where exposure to moisture, saltwater, or harsh weather conditions is common. Another advantage of aluminum profiles is their high strength-to-weight ratio. Aluminum alloys can be engineered to provide exceptional strength while still being lightweight. This makes them an excellent choice for structural applications that require both strength and weight reduction. In addition, aluminum profiles are highly durable and can withstand extreme temperatures. Aluminum has a melting point of 660 degrees Celsius, which is significantly higher than most other non-ferrous metals. This makes it suitable for applications where exposure to high temperatures or thermal stress is expected. Aluminum profiles are also easily fabricated, allowing for complex shapes and designs. They can be extruded, machined, welded, or formed into various configurations to meet specific requirements. This flexibility in manufacturing processes makes aluminum profiles a versatile material choice. However, it is important to note that aluminum profiles may not be suitable for all applications. Steel still offers superior strength and rigidity, making it more appropriate for heavy-duty applications or areas requiring high impact resistance. Additionally, the cost of aluminum profiles can be higher compared to steel, depending on the specific alloy and manufacturing processes involved. In conclusion, aluminum profiles can be considered as a viable alternative to steel or other materials in many applications. Their lightweight nature, corrosion resistance, high strength-to-weight ratio, durability, and ease of fabrication make them an attractive choice for various industries. However, it is crucial to carefully consider the specific requirements of each application before deciding on the most suitable material.

- Q: What are the different surface patterns available for aluminum profiles?

- Some of the different surface patterns available for aluminum profiles include brushed, anodized, powder coated, polished, and textured finishes.

- Q: Can aluminum profiles be used in lightweight construction applications?

- Yes, aluminum profiles can definitely be used in lightweight construction applications. Aluminum is a lightweight and versatile material that offers numerous advantages in construction projects. It has a high strength-to-weight ratio, which means that structures can be built with less material without compromising on strength or durability. This makes it an ideal choice for lightweight construction applications, where reducing weight is a key consideration. Aluminum profiles are commonly used in various construction projects, such as building facades, interior partitions, roofing systems, and structural frameworks. They are particularly popular in industries like aerospace, automotive, and marine, where weight reduction is critical. Furthermore, aluminum profiles offer excellent corrosion resistance, making them suitable for outdoor and high-moisture environments. They are also highly malleable and can be easily fabricated into different shapes and sizes, allowing for customized designs and easy installation. Additionally, aluminum is an environmentally friendly material as it can be recycled indefinitely without losing its properties. In summary, aluminum profiles are widely used in lightweight construction applications due to their lightweight nature, strength, durability, corrosion resistance, malleability, and environmental benefits.

- Q: What are the surface finishes available for aluminum profiles?

- Aluminum profiles offer a range of surface finishes, each with distinct aesthetics and properties. The options for surface finishes include: 1. Mill Finish: This is the standard finish straight from the mill, without any additional treatment. It has a raw look with visible manufacturing marks and is typically used for structural purposes where appearance is not important. 2. Anodized Finish: This finish involves an electrochemical process that forms a protective oxide layer on the aluminum surface, enhancing corrosion resistance and durability. Anodized finishes come in different colors and can have a glossy or matte appearance, making them popular for decorative applications. 3. Powder Coating: This finish involves applying dry powder to the aluminum surface and then curing it in an oven. It offers excellent durability, corrosion resistance, and a wide range of color options. It can also provide different textures, including smooth, matte, or textured, allowing for customization based on specific design needs. 4. Brushed Finish: Achieved by brushing the aluminum surface with abrasive materials, this finish creates fine lines for a brushed appearance. It is often used to add a decorative touch to aluminum profiles and can provide a sleek and modern look. 5. Polished Finish: Polishing entails using abrasive materials to create a smooth and shiny surface on the aluminum. This finish can range from high gloss, mirror-like appearance to a satin finish. It is commonly used in architectural applications where a reflective and visually appealing surface is desired. 6. Wood Grain Finish: This finish involves applying a special coating to the aluminum surface, imitating the look of wood grain. It provides a natural and warm appearance, making it suitable for applications where a wood-like aesthetic is desired without the maintenance requirements of real wood. These examples showcase the variety of surface finishes available for aluminum profiles. The selection of a finish depends on the intended use, desired appearance, and specific requirements such as corrosion resistance, durability, and ease of maintenance.

- Q: This question asks for a method to calculate the quantity of aluminum profiles required for a construction project.

- <p>To calculate the amount of aluminum profiles needed for your building project, first, measure the dimensions of the area where the profiles will be used. Determine the length and width of each profile required. Multiply these dimensions by the number of profiles needed for each section of the project. Add up the totals for all sections to get the overall quantity. Consider the type of profile and its application, as this will affect the quantity and specification. Factor in a small percentage for waste and cutting errors. For complex projects, consult with an engineer or use specialized software to ensure accuracy.</p>

- Q: Who can tell me the latest national standard for aluminum and the latest edition, -2008?

- Are you looking at these? These are new standards for 2008, and there are many I haven't listed. You can come here and see it. It's easy to find!Standard number: GB 5237.1-2008Standard Name: aluminium alloy construction profile first parts: base materialStandard status: not implementedEnglish Title: Wrought, aluminium, alloy, extruded, profiles, for, architecture -, Part, 1:Mill, finish, profilesAlternatives: instead of GB 5237.1-2004Date of implementation: 2009-9-1Promulgated by: China Nonferrous Metals Industry AssociationDescription: this standard specifies the lighting measuring instruments, measuring methods and measurement contents in indoor and outdoor lighting placesThis standard applies to the measurement of indoor lighting, the measurement of outdoor lighting places such as roads, squares and outdoor work areas, and the measurement of night lighting of buildingsStandard number: GB 5237.2-2008Standard Name: aluminum alloy building profile second parts: anode oxidation section

- Q: What are the fire-resistant properties of aluminum profiles?

- Aluminum profiles possess excellent fire-resistant properties due to their high melting point of about 660 degrees Celsius (1220 degrees Fahrenheit). Additionally, aluminum forms a protective oxide layer when exposed to heat, which further enhances its resistance to fire. This oxide layer acts as a barrier, preventing oxygen from reaching the aluminum surface and inhibiting the combustion process. As a result, aluminum profiles are widely used in various applications where fire safety is crucial, such as building construction and transportation industries.

- Q: Are aluminum profiles suitable for use in mining and construction equipment?

- Indeed, mining and construction equipment can benefit from the utilization of aluminum profiles. The unique properties of aluminum make it highly compatible with these industries. Firstly, its lightweight nature aids in reducing the overall weight of the equipment, facilitating easy transportation and maneuverability on construction sites or during mining operations. Moreover, this lightweight characteristic enhances fuel efficiency, thereby decreasing operational costs. Furthermore, aluminum profiles possess exceptional resistance to corrosion, a vital attribute for these industries, where equipment is frequently exposed to severe weather conditions and corrosive substances. This corrosion resistance guarantees the durability and longevity of the equipment, even in challenging environments. Additionally, aluminum profiles offer ease of fabrication and customization to cater to specific requirements. This adaptability in design permits the creation of intricate shapes and structures, enabling the construction of equipment with optimal strength and functionality. Moreover, the high thermal conductivity of aluminum profiles effectively dissipates heat generated during mining and construction operations. This property plays a crucial role in preventing overheating or damage to the equipment, ensuring efficient performance even in intense working conditions. In summary, the combination of lightweight, corrosion resistance, versatility, and thermal conductivity renders aluminum profiles a suitable choice for integration into mining and construction equipment.

- Q: Regarding the wall thickness of aluminum alloy profiles, are there any standards in the country?

- < technical specification for glass curtain wall JGJ102-2003> open section bar is not less than 3.0mm. For example, the beams are mostly open and closed at one end with a cover plate. Closed profiles such as stand up, mostly closed type, not less than 2.5mm, these are only the minimum requirements for wall thickness, but also in accordance with the calculation of the book in the calculation of the wall thickness.

Send your message to us

Customized Colorful Powder Coating Aluminum Door Profile AA6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords