Aluminum Pipes - Aluminium Profile AA6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1 Specifications of Aluminum Profiles 6063-T5

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

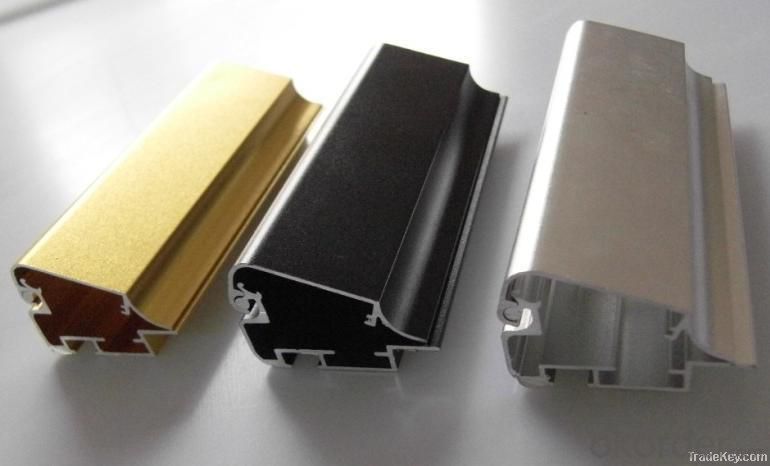

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Profiles 6063-T5

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

- Q: What brand of aluminium tube is in freezer?

- The 7075 is Aluminum Alloy grades, belonging to the Aluminum Alloy 7 Series (1XXX is pure aluminum, Al Cu mg Al Cu Mn is 2XXX or 3XXX, 4XXX generally do manganese aluminum brazing sheet, 5XXX Al Mg, 6XXX Al Mg Si, Al Zn mg Cu 7XXX)7075 chemical compositionFerrosilicon, copper, manganese, magnesium, chromium, nickel, zinc, titanium, other (3) aluminum (4)Each total0.4, 0.5, 1.2-2.0, 0.30, 2.1-2.9, 0.18-0.35 - 5.1-6.1, 0.20 (5), 0.05, 0.15, remainder

- Q: Are aluminum pipes suitable for chemical refineries?

- Yes, aluminum pipes are generally not suitable for chemical refineries due to their reactivity with various chemicals, potential corrosion, and lower strength compared to other materials like stainless steel or carbon steel which are commonly used in such environments.

- Q: What are aluminum pipes made of?

- Aluminum pipes consist mainly of aluminum, a metal that is both lightweight and resistant to corrosion. The process of extracting aluminum from bauxite ore and refining it through a series of procedures yields pure aluminum. This pure aluminum is subsequently melted and shaped into cylindrical forms to manufacture aluminum pipes. The addition of different alloys is possible to improve the strength, durability, and various other characteristics of the aluminum pipes, based on their intended purposes. In summary, aluminum pipes are primarily made of aluminum, rendering them suitable for diverse applications across industries like construction, automotive, aerospace, and plumbing.

- Q: Such questions. Recently prepared to buy an umbrella with the baby, too heavy to hold for a long time can not stand. Taobao took a look, the style is colorful. I saw 3 stalls tent, but there are two kinds of pipes, do not know what kind of practical. Steel pipe should be relatively strong and durable, the aluminum tube is characterized by light, but worried that the baby sit on top of instability. How do moms choose?

- The umbrella car is better than the aluminum tube.The heat exchange of aluminum is faster than that of steel, so the cooling speed is faster and the cost is almost the same as steel. Because aluminum will not rust, so the latter does not need steel platoon, as rust preventive maintenance.

- Q: What is the tensile strength of the 6063T5 aluminum tube and what is the elongation rate?

- The tensile strength of 6063T4 aluminium tubes is about 150. The elongation rate is about 10%. T6's around 230. The elongation rate is about 8%As it were, you can Q me: 88099379 (Shanghai Xuan Sheng)

- Q: What are the different coating options for aluminum pipes?

- There are several different coating options available for aluminum pipes, depending on the specific application and requirements. Some of the most common coating options for aluminum pipes include: 1. Anodizing: Anodizing is a popular coating method for aluminum pipes as it provides enhanced corrosion resistance and durability. It involves creating an oxide layer on the surface of the aluminum, which can be further colored or dyed to improve aesthetics. 2. Powder coating: Powder coating is a dry finishing process where a powder is electrostatically applied to the aluminum pipe surface. It is then cured under heat, forming a hard and durable coating. Powder coating offers excellent corrosion resistance and can be customized with various colors and textures. 3. Epoxy coating: Epoxy coatings are often used for aluminum pipes that will be exposed to harsh environments or chemicals. Epoxy coatings provide excellent chemical resistance, high adhesion, and protection against corrosion. These coatings are typically applied through a spray or dip process. 4. Polyethylene coating: Polyethylene coatings, commonly known as PE coating, are commonly used for aluminum pipes that will be buried underground or used in corrosive environments. PE coatings provide a protective barrier against corrosion and abrasion, ensuring the longevity of the pipe. 5. Thermal spray coatings: Thermal spray coatings involve applying a layer of metal or ceramic material onto the aluminum pipe surface using a high-temperature process. These coatings offer enhanced wear resistance, thermal insulation, and corrosion protection. 6. Ceramic coatings: Ceramic coatings provide excellent heat resistance and can be used for aluminum pipes that will be exposed to high temperatures. These coatings offer thermal insulation, protection against oxidation, and can improve the overall performance of the pipe in extreme conditions. It is important to note that the selection of a specific coating option for aluminum pipes should consider factors like the intended use, environmental conditions, aesthetics, and budget. Consulting with coating experts or professionals can help determine the most suitable coating option for a particular application.

- Q: Please help to analyze the cause of the formation Fifty1070 aluminum rods are made of aluminum tubes from extrusion units. The process is: extrusion, melting - the mold passes through (the formation of aluminum tubes) - tap water cooling - closing - nitrogen charging and pressure maintaining. Therefore, the internal pipeline is nitrogen protection, and after a period of time, the pipeline will appear white powder, affecting resistance welding, welding is not firm, easy to fall off and leak.

- AskIn fact, we suspect that it is alumina, but I don't know how to avoid it.Chasing the answerThere are two best ways:1. Keep the environment air dry.2. Apply anti oxidation coating for pipes.Or third: strengthen daily cleaning.

- Q: Why is copper pipe used instead of copper aluminum composite tube or aluminium pipe?

- Pipe is widely used. Pipes are used in many industries.Different industries have different characteristics of the industry, and thus have different technical requirements.Pipe is a relatively mature product, each industry has the corresponding technical standards.Detect pipe material, according to the application of pipe industry, select the corresponding product standards, according to the industry needs to detect the corresponding technical indicators.

- Q: Aluminium tube production and equipment. What are the production techniques and what equipment are needed? How much will it cost?.

- Familiar with TS16949 quality management system, master of the world's most advanced welding equipment maintenance, equipment procurement and acceptance leading technology used debugging, equipment maintenance and leadership team, prepare equipment maintenance work instruction form, prepare equipment.

- Q: Are aluminum pipes suitable for drinking water applications?

- Yes, aluminum pipes are generally suitable for drinking water applications. Aluminum is corrosion-resistant and does not leach harmful chemicals into the water, making it a safe choice for transporting drinking water. However, it is important to ensure that the pipes are properly coated or lined to prevent any contact between the water and the aluminum surface. Additionally, regular maintenance and inspections are necessary to detect any signs of corrosion or degradation that may compromise water quality.

Send your message to us

Aluminum Pipes - Aluminium Profile AA6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches