Ollivander's Aluminum Sheets - Powder Coated Aluminum Door Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Door Profile of Powder Coating Description:

Aluminum Door Profile of Powder Coating (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of Aluminum Door Profile of Powder Coating :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

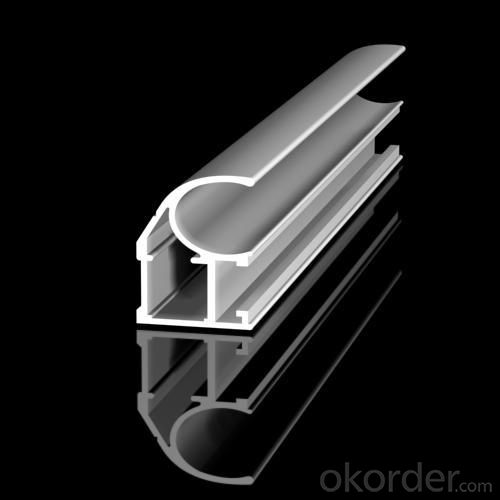

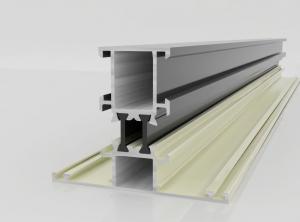

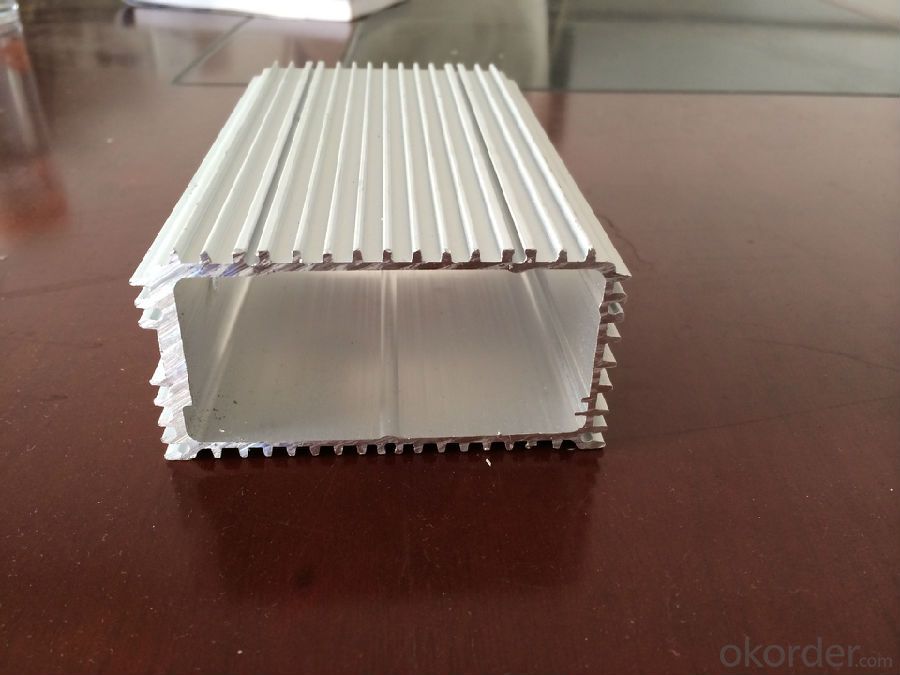

3.Aluminum Door Profile of Powder Coating Images:

4.Aluminum Door Profile of Powder Coating Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of alloys used for painted aluminum sheets?

- Painted aluminum sheets commonly utilize various types of alloys. Among them, 3003 stands out as a favored option due to its exceptional corrosion resistance and high formability. This alloy finds extensive use in industries like automotive, where a smooth surface finish is preferred. Another frequently employed alloy is 5052, which provides superior strength compared to 3003. Its remarkable resistance to corrosion and ability to endure harsh environments make it suitable for marine and architectural applications. Moreover, it is renowned for its weldability and formability. 6061 is also a well-liked choice for painted aluminum sheets. Its notable attributes include high strength and excellent machinability. This alloy is often employed in structural applications, such as the production of aircraft parts and automotive components. Furthermore, painted aluminum sheets may incorporate other alloys like 2024, 5754, and 7075. These alloys possess specific properties that render them suitable for particular applications, such as elevated strength or improved corrosion resistance. In essence, the selection of the alloy for painted aluminum sheets hinges upon the specific requirements of the application, such as desired strength, corrosion resistance, and formability.

- Q: I need some aluminum sheets for an art project. I'm not sure where to find such a thing, though. I've looked at Home Depot briefly and aluminum flashing is the closest thing I've found. Flashing comes in a roll and is just a bit too thin. I need flat sheets of aluminum that are somewhat stiff, but not more than, say, 1/4 thick. Are there any stores that sell such things? A larger sheet would be fine if I could either get it cut at the store or find some way to cut it to the size I want. How do you cut aluminum, anyway? Any suggestions are greatly appreciated!

- any contractor that does heating and coolin..... or a contruction site in your area

- Q: which has greater density 5 kg of lead or 10 kg of aluminum

- lead it has the Atomic Weight of= 207.2

- Q: Which kind of glue is best for bonding wood and aluminum sheet together?

- You can use 502 adhesive.

- Q: avaliable in the uk preferably in a high street store and preferably anti-perperant aswell

- Are you allergic to aluminum or are you refusing to use it because it is not natural? Aluminum has solid research to back its antiperspirant ability. As long as the deodorant or antiperspirant is well-formulated, it is good. There is no best. You should make a search on Amazon UK with key word like natural or organic deodorant or antiperspirant because those terms usually filter out aluminum ones. But, whether or not it will be effective is a different story.

- Q: how to separate the aluminum sheet in plastic?

- Put them into clean water if both of them won’t react with water, and aluminum sheet will sink into the bottle, then fish up them separately.

- Q: What are the different types of aluminum sheets available?

- There are several different types of aluminum sheets available, including plain aluminum sheets, embossed aluminum sheets, perforated aluminum sheets, and painted aluminum sheets. Each type has its own unique attributes and applications.

- Q: Are aluminum sheets resistant to abrasion?

- Yes, aluminum sheets are generally resistant to abrasion due to their hardness and durability.

- Q: How do you clean aluminum sheets?

- Achieving cleanliness for aluminum sheets involves a few straightforward steps: 1. Initiate the process by eliminating any loose dirt or debris from the aluminum sheet's surface. Use a soft brush or cloth to gently sweep away any particles. 2. Create a cleaning solution by combining warm water with a mild detergent or dish soap. It is crucial to avoid strong chemicals or abrasive cleaners since they can harm the aluminum. 3. Submerge a soft cloth or sponge into the cleaning solution and delicately scrub the aluminum sheet. Ensure that the entire surface is covered, giving extra attention to any stains or spots. 4. In the case of persistent stains or marks, utilize a non-abrasive cleaner specifically designed for aluminum. Apply the cleaner onto a soft cloth and gently rub it onto the affected area until the stain is eliminated. 5. Thoroughly rinse the aluminum sheet with clean water to eliminate any soap residue. This step is vital to prevent the accumulation of residue or streaks on the surface. 6. Dry the aluminum sheet completely using a soft towel or cloth. Verify that there is no remaining moisture as it can lead to water spots or corrosion over time. 7. To enhance shine and provide protection, apply a thin layer of aluminum polish or wax. This procedure aids in restoring the luster and safeguarding the aluminum from future tarnish or oxidation. It is important to acknowledge that the cleaning technique may differ based on the type of dirt or oxidation present on the aluminum sheet. Always refer to and adhere to the manufacturer's instructions for specific cleaning recommendations.

- Q: Can aluminum sheet be bent or formed into different shapes?

- Indeed, aluminum sheet possesses the capacity to be effortlessly bent or molded into diverse forms. As a remarkably ductile metal, aluminum can be bent, shaped, or molded without any risk of cracking or fracturing. This characteristic renders it a perfect selection for a wide array of applications where adaptability and customization are essential. Multiple techniques, including the utilization of a brake press, roll forming, or specialized bending tools, can be employed to bend aluminum sheets. The degree of bendability may vary based on the thickness and grade of the aluminum sheet. Nevertheless, in general, aluminum is renowned for its exceptional malleability and aptitude to assume various configurations.

Send your message to us

Ollivander's Aluminum Sheets - Powder Coated Aluminum Door Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords