Customized Color Coated Aluminum Coil - Aluminum Profile 6060 6061 6063 6082 Grade

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Profile 6060 6061 6063 6082 Grade Aluminium ProfileDescription:

Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

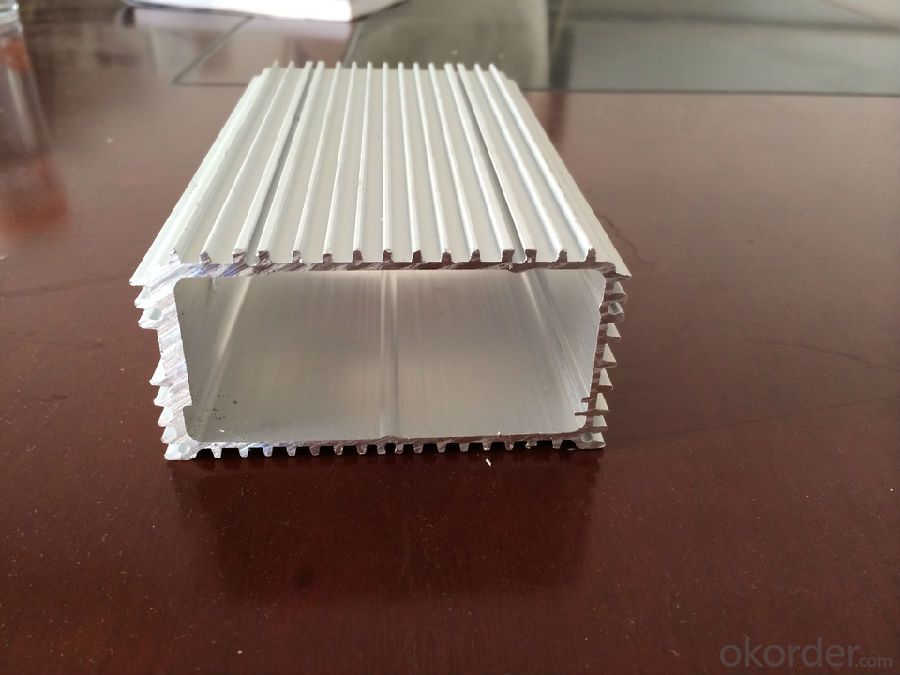

3.Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile Images:

4.Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are aluminum coils used in the production of transportation vehicles?

- Aluminum coils are used in the production of transportation vehicles primarily for their lightweight and durable properties. These coils are typically used to manufacture various components, such as body panels, frames, and engine parts. The use of aluminum helps reduce the overall weight of the vehicle, enhancing fuel efficiency and performance. Additionally, aluminum's corrosion resistance makes it ideal for withstanding harsh weather conditions and extending the lifespan of the vehicle.

- Q: The question asks if magnetic induction can be used to inspect the quality of an aluminum coil.

- <p>No, you cannot use magnetic induction to inspect the quality of an aluminum coil. Magnetic induction is a method used to detect flaws or discontinuities in ferromagnetic materials, such as steel, by inducing eddy currents. Aluminum is not a ferromagnetic material, so it does not retain magnetism or support the formation of eddy currents in the same way. Instead, other non-destructive testing methods like ultrasonic testing or radiographic testing may be more appropriate for inspecting the quality of aluminum coils.</p>

- Q: Why are the aluminum coils sticky after annealing?

- There is oil or the annealing time is too long!

- Q: What is the typical coefficient of thermal expansion for aluminum coils?

- Aluminum coils usually have a coefficient of thermal expansion around 23 x 10^-6 per degree Celsius. This implies that with each degree Celsius rise in temperature, the length of the aluminum coil will expand by 23 parts per million. The coefficient of thermal expansion holds significance in the design and handling of aluminum coils, as it impacts their dimensional stability and can induce thermal strains in the material due to temperature fluctuations.

- Q: What are the potential risks of using aluminum coils in specific applications?

- The potential risks of using aluminum coils in specific applications include corrosion, especially in environments with high humidity or acidic conditions. Aluminum coils are also more susceptible to damage and denting compared to other materials. Additionally, aluminum coils may have lower heat transfer capabilities, which could affect the efficiency of certain applications.

- Q: Is it safe and effective to use aluminum coil for baking purposes?

- <p>Yes, aluminum coil can be used for baking. It is a common material in baking due to its excellent heat conductivity, which allows for even heating and browning of baked goods. However, it's important to ensure that the aluminum coil is food-grade and clean to avoid any contamination. Additionally, some people may be concerned about potential health risks associated with aluminum, although these concerns are generally considered minimal when using aluminum cookware for baking.</p>

- Q: Are aluminum coils suitable for low-maintenance applications?

- Indeed, low-maintenance applications are well-suited for the use of aluminum coils. Renowned for its strength and ability to resist corrosion, aluminum proves to be an exceptional selection for applications that demand minimal upkeep. Unlike alternative materials like steel, aluminum coils remain free from rust and do not necessitate regular painting to preserve their aesthetic appeal. Furthermore, the lightweight nature of aluminum facilitates effortless installation and handling, particularly in low-maintenance scenarios where frequent maintenance may prove impractical or undesirable. Ultimately, aluminum coils serve as a dependable and low-maintenance solution for a range of applications.

- Q: How is Aluminum formed??Thanks!!

- I don't think any significant quantity of aluminum is produced by reduction with carbon - aluminum is too reactive for this to give a good yield. Instead, the metal is produced by electrolysis in the Hall-Heroult process. First, aluminum ore is processed to aluminum oxide in the Bayer process. This ore, bauxite, consists of aluminum oxides and hydroxides with some impurities, mostly iron oxides. The aluminum oxide/hydroxides are dissolved with concentrated sodium hydroxide in water. Iron oxides and hydroxides do not dissolve, and are filtered out. AlOOH (insoluble in water) + NaOH + H2O ----- NaAl(OH)4 (soluble in water) Neutralizing or cooling this solution will cause aluminum hydroxide to precipitate out. This is then heated strongly to drive off water and produce aluminum oxide. 2Al(OH)3 ----- Al2O3 + 3H2O This aluminum oxide can be melted and then electrolyzed to make the metal and oxygen gas. However, the melting point of aluminum oxide is very high, so it is dissolved in molten cryolite (Na3AlF6), which has a lower melting point. This is then electrolyzed, and molten aluminum collects at the bottom of the cell (cathode), where it can be drawn off. Because the oxygen that would be formed will attack most metal electrodes, a sacrificial carbon electrode is used for the anode and is oxidized to CO2. Very small amounts of aluminum metal occur in nature - it is usually found in association with fossil fuel deposits (which provide the reduced carbon necessary to reduce aluminum minerals).

- Q: The heat of fusion of aluminum is 3.95kj/g. What is the molar heat of fusion of aluminum? What quantity of energy is needed to melt 10.0g of aluminum? What quantity of energy is required to melt 10.0 mol of aluminum? Three questions i need help with can someone show me step by step please so i can get it thank you a bunch

- Two multiplications will solve your problem: Q1 = m1 x Del(Hf) Q1 = (14.5 x 0.395) kJ = 5.73 kJ Q2 = n2 x Del(Hmol) Q2 = (14.5 x 107) kJ ~ 1,552 kJ

- Q: Is it possible to utilize a grinder for cutting aluminum coils?

- <p>Yes, you can use a grinder to cut aluminum coils, but it's important to use the right type of grinder and accessories. An angle grinder with a cutting wheel or a metal cutting disc is suitable for this task. Ensure the grinder is equipped with a safety guard and that you're wearing appropriate safety gear, such as goggles and gloves. Be cautious as aluminum can be slippery and the grinder can generate a lot of heat, which may require frequent cooling to prevent the disc from burning out. It's also advisable to work in a well-ventilated area due to the fine particles produced during cutting.</p>

Send your message to us

Customized Color Coated Aluminum Coil - Aluminum Profile 6060 6061 6063 6082 Grade

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords