Powder Coated Mill Finish Aluminum Sheets for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminium Sheet for Curtain Wall

Alloy Number | AA1xxx 3xxx 5xxx |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Mill Finish Aluminium Sheet for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminium Sheet for Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

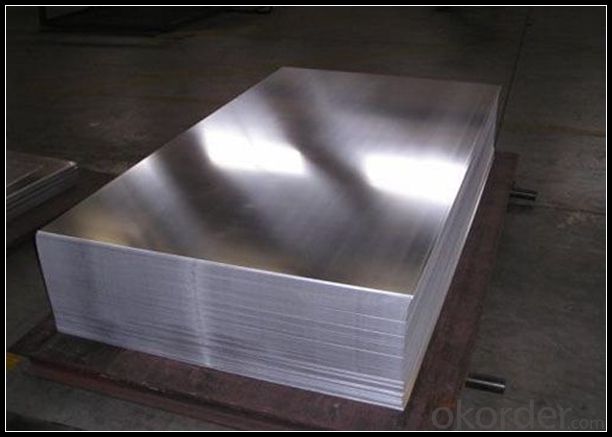

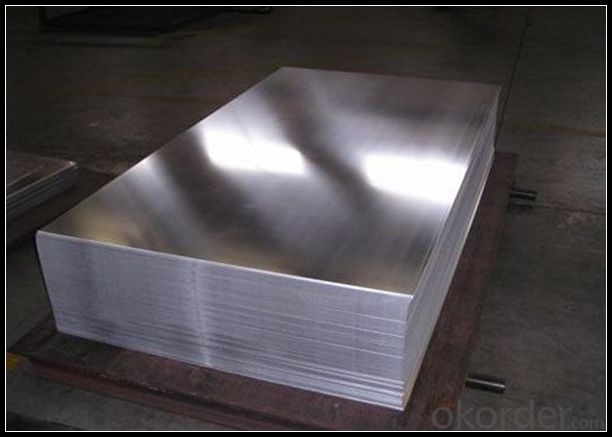

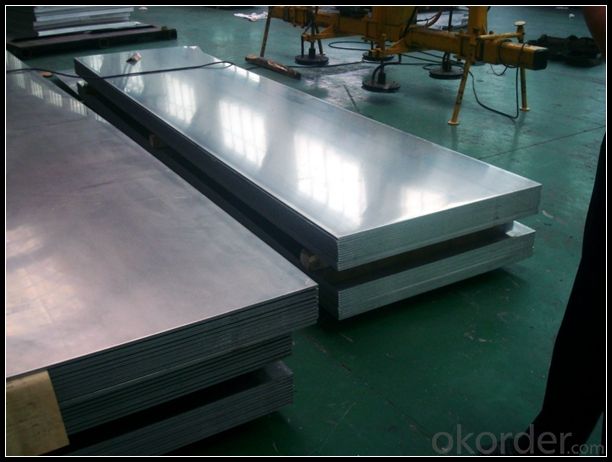

5. Image of Mill Finish Aluminium Sheet for Curtain Wall

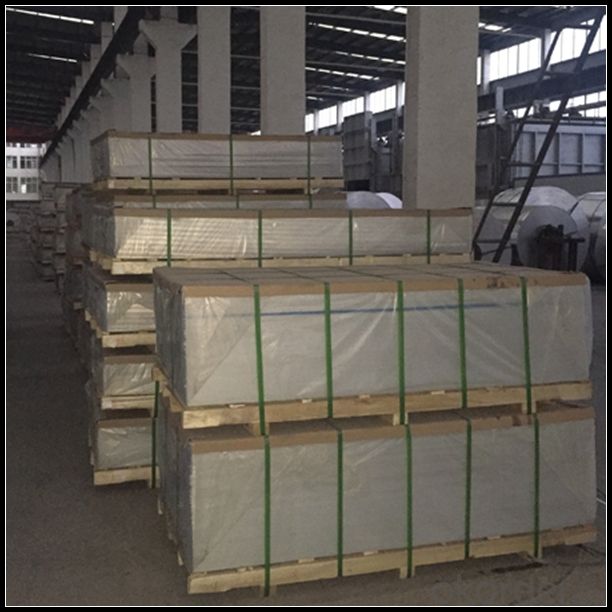

6. Package and shipping of Mill Finish Aluminium Sheet for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How does the surface roughness affect the friction properties of aluminum sheet?

- The surface roughness of an aluminum sheet affects its friction properties by increasing the surface area in contact with another object, leading to higher frictional forces. A rougher surface will have more irregularities and asperities, creating more points of contact and interlocking with the opposing surface. This increased contact area enhances the adhesion between the surfaces, resulting in higher friction. Conversely, a smoother surface with fewer irregularities will have reduced contact area and less adhesion, leading to lower friction.

- Q: What is the lifespan of aluminum sheets?

- Various factors, such as the aluminum's grade and thickness, the environmental conditions it encounters, and the level of maintenance it receives, can impact the lifespan of aluminum sheets. Aluminum sheets are renowned for their durability and resistance to corrosion, which contributes to their long lifespan. Aluminum possesses natural resistance against rust and corrosion, making it suitable for a wide array of applications. When given proper care and maintenance, aluminum sheets can endure for numerous years. The construction, automotive, and aerospace industries frequently utilize aluminum sheets due to their lightweight nature and robust properties. In outdoor settings, aluminum sheets can withstand harsh weather conditions, including extreme temperatures, humidity, and exposure to UV radiation. Nevertheless, continuous exposure to certain chemicals or corrosive substances can gradually cause damage. To prolong the lifespan of aluminum sheets, it is crucial to regularly clean and safeguard them. This entails eliminating any dirt or debris that might accumulate on the surface and applying protective coatings or treatments as necessary. In conclusion, while it is challenging to provide an exact timeframe for the lifespan of aluminum sheets, they are generally regarded as a long-lasting material that can withstand the test of time when adequately maintained.

- Q: What specific conditions or regulations must be met when using aluminum sheets in commercial construction?

- <p>Yes, there are special requirements for using aluminum sheets in commercial buildings. These include adherence to building codes and standards for fire resistance, structural integrity, and weather resistance. Aluminum sheets must meet specific thickness and strength requirements depending on the application. They also need to comply with environmental regulations regarding sustainability and recyclability. Additionally, for aesthetic purposes, the finish and color of the aluminum sheets should be in line with architectural design guidelines. It's crucial to consult with architects, engineers, and local building authorities to ensure all requirements are met.</p>

- Q: Can aluminum sheets be used for bus shelters?

- Yes, aluminum sheets can be used for bus shelters. Aluminum is a lightweight and durable material that can withstand harsh weather conditions, making it suitable for outdoor structures like bus shelters. Additionally, aluminum can be easily fabricated and customized to meet the specific design requirements of bus shelters.

- Q: Can aluminum sheets be used for packaging?

- Yes, aluminum sheets can be used for packaging. Aluminum is a versatile and widely used material in the packaging industry due to its numerous advantageous properties. It is lightweight, strong, durable, and resistant to corrosion, making it an ideal choice for packaging applications. Aluminum sheets can be easily formed into various shapes and sizes, providing flexibility in design and customization. Additionally, aluminum is impermeable to light, moisture, gases, and microorganisms, ensuring the preservation and protection of the packaged goods. It is also a good conductor of heat, which allows for efficient heat transfer during processes like sterilization or pasteurization. Furthermore, aluminum is recyclable, making it an environmentally friendly packaging option. Overall, aluminum sheets are an excellent choice for packaging due to their excellent properties and versatility.

- Q: What kind of aluminum sheet can be bent with five millimeters?

- The aluminum plate can be bent five milimeter too much, if only bending words and aluminum quality has little relationship.First of all, the state is the most important, the state is divided into hard, semi hard, soft (usually soft called O state)The bending effect of the whole hard is not too far (the aluminum plate is H18, H19, H38 and so on are all hard)Semi hard aluminum sheets can basically be bent (H24, that is, semi hard)O bending is certainly not a problem, but because of too soft, basically with this state to bend lessSecond, you have to choose pure aluminum or alloy aluminum?Pure aluminum hardness is not very good, with 1100, 1050, 1060 and so on can be recommended 1100 H26Alloy aluminum hardness is better, can use 3003, 3005, 5052 and other semi hard state can be.Specific recommendations were then determined by 6061, 2024, 7075 if the hardness is too high, especially for the T6 state is more, should not bend, unless you're heating and folding the difference between aluminum and aluminum is poor oxidation resistance, tolerance, surface effect, crystal accuracy and the uniform stability of a difference, not only the bending effect difference.If the aluminum surface paint it quality do not too good, good is a waste, it is recommended to use 3003-H26, 3005H24 or 5052H34, the price of twenty pieces of it, made up to more than forty yuan per kilogram

- Q: This question asks for an explanation of the various types of coatings applied to aluminum sheets that are used outdoors.

- <p>Aluminum sheets used for exterior applications are often coated to enhance their durability, weather resistance, and aesthetic appeal. The different types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a dry finishing process that provides a uniform and durable finish. 3. PVDF (Polyvinylidene Fluoride) coating, known for its excellent resistance to UV rays and chemicals. 4. Fluorocarbon coatings, which offer superior resistance to weathering and color retention. 5. Electrolytic coating, which involves the application of a thin protective layer through an electrochemical process. Each coating type has specific properties that make it suitable for different exterior applications and environmental conditions.</p>

- Q: How much weight/people can a 12ft aluminum boat hold?and if anyone knows how much weight can a 6.5hp motor push around

- You should have a small metal plate that is riveted into the rear transom that will tell you what the max. capacity, persons and weight. If this is absent, I would answer the question by saying that if your boat is of the John boat variety, (square front end) and pretty shallow sides, I would think twice about 2 large people that weigh 225+. If your boat is of the deep-V variety with deeper sides, then two people with gear would probably be fine. Any way you look at it, a 10 boat is a maximum of twp persons.

- Q: Is it possible to substitute aluminum sheets for wood siding in construction?

- <p>Yes, you can use aluminum sheets to replace wood siding. Aluminum siding is a popular alternative to wood for several reasons. It is lightweight, durable, and resistant to rot, insects, and moisture. It also requires less maintenance than wood and can be painted to match various aesthetic preferences. However, it's important to consider factors such as insulation properties, cost, and the look you want to achieve, as aluminum may not perfectly mimic the appearance of wood. Always consult with a professional to ensure proper installation and compatibility with your home's architecture.</p>

- Q: Does exposure to ultraviolet (UV) rays impact the properties or longevity of aluminum sheets?

- <p>Aluminum sheets are generally resistant to UV rays, which means they do not degrade or corrode due to exposure to sunlight or UV radiation. Aluminum has a high reflectivity and can reflect most of the UV rays, minimizing the impact on its surface. However, prolonged exposure can cause a slight change in color, known as patina, which is a natural oxidation process and does not compromise the integrity or strength of the material. Overall, aluminum maintains its properties well under UV exposure, making it a suitable material for outdoor applications.</p>

Send your message to us

Powder Coated Mill Finish Aluminum Sheets for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords