Polypropylene Filter Non-woven Geotextile Fabric 300gsm for Railway

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

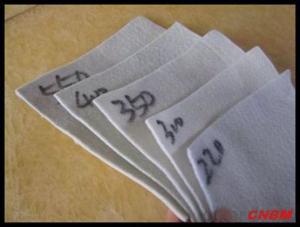

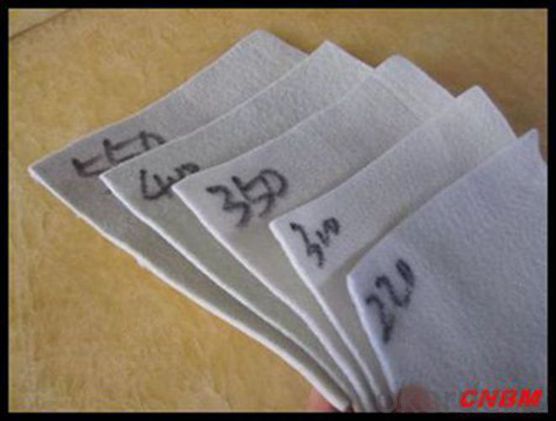

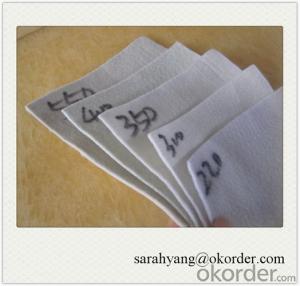

Mass Per Unit Area: 100-900g/m2

Fiber Type: Staple fiber

Color: White, Black, Grey etc.

Width Range: 1-6m

Length: as consumer request

Weight: 200g/m2--800g/m2

Width: 1m-4m

Length: 30m-60m

Color: Any colors available or customers colors

Packing: Transparent polybag or White PP woven bag

Technics: Needle punchded/non woven

Productivity: More than 10000 sqms/day

Place of origin: Shandong, China

Load quantity Around 4000-12000m2 in 1x20ft

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help with filtration in stormwater management?

- Geotextiles are used in stormwater management to help with filtration by acting as a barrier that prevents the passage of fine particles while allowing water to pass through. This helps to remove pollutants and sediments from stormwater runoff, improving water quality before it enters natural water bodies or is discharged into the environment.

- Q: How do geotextiles help in preventing erosion around culverts?

- Geotextiles help prevent erosion around culverts by acting as a protective barrier that stabilizes the surrounding soil. They are installed to prevent soil movement and filter out any sediments, allowing water to flow freely while retaining the integrity of the soil structure. This helps to prevent erosion, maintain the stability of the culvert, and enhance its overall longevity.

- Q: Geotextile how much money a square

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: How do geotextiles help with reinforcement of geotextile bags?

- Geotextiles help with the reinforcement of geotextile bags by providing added strength and stability to the bags. They act as a barrier between the soil and the bag, preventing soil erosion and maintaining the shape and integrity of the bags. Geotextiles also distribute loads evenly across the bag's surface, reducing the stress on the bag and enhancing its overall performance in reinforcement applications.

- Q: How do geotextiles help with soil stabilization in slope stabilization projects?

- Geotextiles play a crucial role in soil stabilization during slope stabilization projects. They are designed to be placed between layers of soil to enhance their structural stability. Geotextiles act as a barrier, preventing soil erosion and promoting water drainage. By providing reinforcement, they distribute the load across a wider area, reducing the pressure on the slope and minimizing the risk of landslides. Additionally, geotextiles help to retain moisture in the soil, which aids in vegetation growth, further strengthening the slope. Overall, geotextiles are an effective solution for soil stabilization in slope stabilization projects.

- Q: Are geotextiles suitable for high-traffic areas?

- Yes, geotextiles are suitable for high-traffic areas. They are designed to provide stability, reinforcement, and filtration in soil and can effectively distribute loads. Geotextiles can help enhance the durability and longevity of high-traffic areas such as roads, parking lots, and walkways.

- Q: Are geotextiles effective in preventing weed growth?

- Yes, geotextiles are effective in preventing weed growth. These permeable fabrics act as a barrier, preventing sunlight from reaching the soil and providing an effective weed control method.

- Q: Can geotextiles be used in coastal revetment projects?

- Yes, geotextiles can be used in coastal revetment projects. Geotextiles are commonly used in coastal engineering to reinforce and stabilize soil and sediment in coastal areas. They can be used as a filter layer to prevent erosion, as a barrier to control water flow, or as a reinforcement layer to enhance the stability of revetment structures. Geotextiles offer several advantages in coastal revetment projects, including improved durability, reduced maintenance, and increased resilience to wave action and tidal forces.

- Q: How do geotextiles contribute to the safety of transportation infrastructure?

- Geotextiles play a vital role in enhancing the safety of transportation infrastructure by providing reinforcement, filtration, and separation. They help prevent soil erosion and stabilize the ground, reducing the risk of landslides and sinkholes. Geotextiles also assist in controlling water drainage and filtration, preventing waterlogging and increasing the durability of roads and bridges. Overall, geotextiles contribute to the longevity and stability of transportation infrastructure, ensuring safer and more reliable travel for users.

- Q: Where is the sale of geotextiles in Tibet?

- Tibet geotextile, a variety of specifications, & lt; Ji Han irrigation pit thieves ghosts and bursonoids p & gt;

Send your message to us

Polypropylene Filter Non-woven Geotextile Fabric 300gsm for Railway

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords