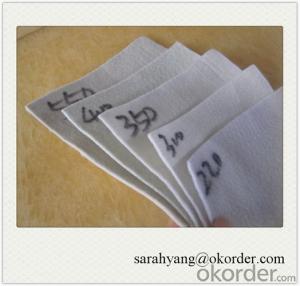

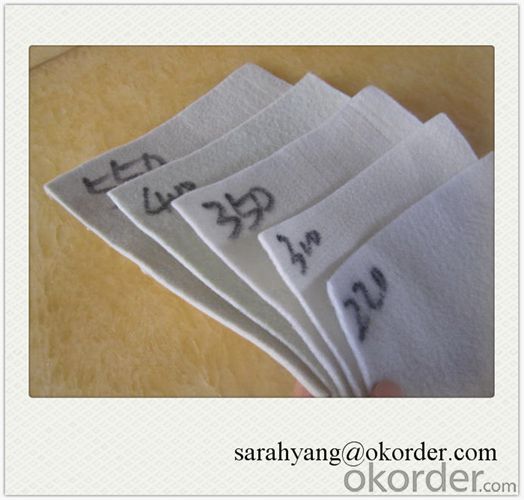

Geotextile 300g M2 Polypropylene Filter Non-Woven Geotextile for Highway, Railway, Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

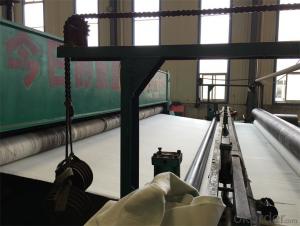

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

Use of polyester staple fiber nonwoven fabric with different physical properties (particle size, distribution, consistency and density, etc.) of the building materials (such as soil and sand, soil and concrete, etc.) in isolation. Make no loss between two or more materials, not mixed, maintains the whole structure and function of material, to reinforce structure load bearing capacity.

Filament Spunbond Nonwoven Geotextile Property:

Good creep property and hydraulics property,resistance to corrosion,

excellent anti-aging and heat-resistance quality.

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FQR

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: How do geotextiles help in preventing soil erosion in vineyards?

- Geotextiles help prevent soil erosion in vineyards by providing a protective barrier between the soil and external factors such as rain, wind, and water runoff. These textile materials effectively stabilize the soil by minimizing surface erosion, controlling sediment movement, and promoting the retention of moisture. Additionally, geotextiles enhance soil structure and allow for better root growth, preventing the loss of valuable topsoil and preserving the vineyard's overall health and productivity.

- Q: What type of geotextile is used for soccer field

- Generally with permeable geotextile, 200g300g can be

- Q: How do geotextiles help in preventing soil erosion in construction sites?

- Geotextiles help prevent soil erosion in construction sites by acting as a barrier between the soil and any external forces, such as wind or water. They stabilize the soil, allowing for proper drainage while also preventing the loss of soil particles. Additionally, geotextiles provide reinforcement to the soil, reducing the potential for erosion and ensuring the stability of the construction site.

- Q: Under what circumstances drainage pipes need additional geotextiles

- Infiltration of water under the circumstances, geotextile play a filtering effect, Huazhi geotextile material manufacturers

- Q: Filament, preferably concrete construction

- Tianhai new material filament geotextile case analysis of water conservancy projects: seawall, river embankment, lake embankment project; reservoir reinforcement project; reclamation project; flood control and rescue. Highway and railway engineering: soft foundation reinforcement treatment; slope protection; road anti-reflective crack structure layer; drainage system; green isolation zone. Electrical engineering: nuclear power plant basic engineering; thermal ash dam project; hydropower project.

- Q: Subgrade geotextile lap law need to suture it

- General geotextiles require stitching. Geotextile stitching must be carried out continuously. Before the overlap, the geotextile must overlap at least 150mm. The minimum seam distance from the geotextile edge is not less than 25mm.

- Q: What are the key considerations for geotextile installation in areas with high seismic activity?

- When installing geotextiles in areas with high seismic activity, there are several key considerations that need to be taken into account. Firstly, the geotextiles should be designed to withstand the ground movements and vibrations caused by earthquakes. This may involve using geotextiles with high tensile strength and puncture resistance. Secondly, proper anchoring and securing techniques should be employed to ensure that the geotextiles remain in place during seismic events. This may include using appropriate fixing methods such as soil nails or ground anchors. Additionally, the selection of geotextile materials should consider their ability to resist degradation caused by the cyclic loading and ground movements associated with earthquakes. Overall, the key considerations for geotextile installation in areas with high seismic activity involve designing for seismic forces, securing the geotextiles effectively, and choosing durable materials that can withstand the effects of earthquakes.

- Q: Are geotextiles suitable for use in landfill applications?

- Yes, geotextiles are suitable for use in landfill applications. They are commonly used as a protective layer to separate different materials in landfills, providing filtration and drainage capabilities. Geotextiles help prevent the mixing of waste materials, facilitate leachate collection, and enhance overall stability and performance of landfills.

- Q: There is no geotextile in the sand filter with the biological retention

- You can use geotextile filter, I am specializing in the production of geotextiles

- Q: What are the advantages of using geotextiles in agriculture?

- Geotextiles offer several advantages in agriculture. Firstly, they help in soil erosion control by preventing the loss of topsoil and retaining moisture. Secondly, they aid in weed suppression, reducing the need for herbicides and manual weeding. Additionally, geotextiles assist in soil stabilization, enhancing the structural integrity of the soil and preventing erosion on slopes. Lastly, they promote better drainage, allowing excess water to flow away while retaining essential nutrients in the soil.

Send your message to us

Geotextile 300g M2 Polypropylene Filter Non-Woven Geotextile for Highway, Railway, Dam

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords