Geotextil De Polipropileno Short Non-Woven Geotextile Fabric 300gsm for Railway-CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. High tension.Because it's made of Plastic flat yarn,it can keep enough tenacity and stretching.

2. Non-corrosive.It can be non-corrosive for long time in soil and water with different PH value.

3. Good Water Permeability.There is space between flat yarn,so it has good water permeability.

4. Good antimicrobic. For organisms,there will be no worm-holes.

5. Easy construction.Because of light material,soft,it's easy for transportation,spreading out and construction.

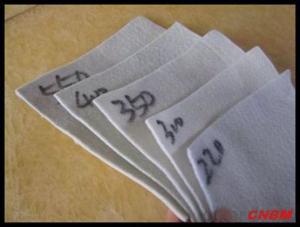

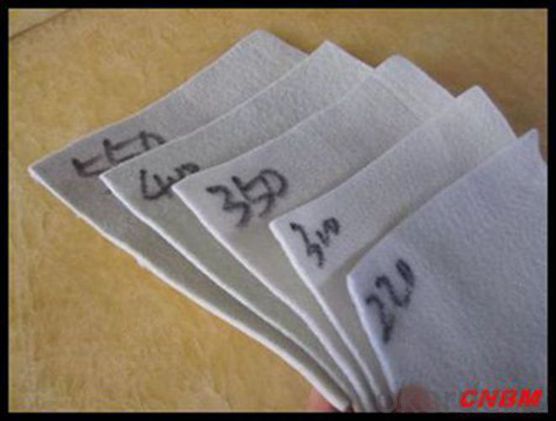

short fiber geotextile

Key Specifications/Special Features:

Specifications

1) PET geotextile: non woven geotextile

2) Material: PP (polypropylene) or Polyester fibers

3) 100g/sq.m-1000g/sq.m

4) Width: 2m-6.5m

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles affect plant growth?

- Geotextiles can positively impact plant growth by providing a stable environment for roots, preventing soil erosion, and promoting moisture retention. Additionally, they control weed growth, regulate soil temperatures, and enhance nutrient availability, ultimately leading to healthier and more productive plants.

- Q: Can geotextiles be used in geosynthetic clay liner applications?

- Yes, geotextiles can be used in geosynthetic clay liner applications. Geotextiles are often used as a protective barrier on both sides of the geosynthetic clay liner to enhance its performance and prevent punctures or damage. They help in retaining fine particles within the liner while allowing water to pass through, making them an essential component in geosynthetic clay liner applications.

- Q: What are the key considerations for geotextile installation in high wind areas?

- The key considerations for geotextile installation in high wind areas include selecting a high-strength geotextile material, ensuring proper anchoring and securing methods, evaluating the site's wind load potential, and implementing effective quality control measures to ensure the installation's durability and long-term performance.

- Q: How do geotextiles contribute to soil filtration?

- Geotextiles contribute to soil filtration by acting as a barrier that allows water to pass through while retaining soil particles. They enhance the filtration process by preventing the migration of fine particles and protecting the underlying soil from erosion.

- Q: What is the difference between polypropylene geotextile, polypropylene geotextile and polyester geotextile

- The raw material is not the same as the clothes have the same cotton polyester tea is the same characteristics of the characteristics of acid-resistant polyester anti-purple better look at where to see where the 4935 penguins

- Q: What are the installation guidelines for geotextiles used in erosion control blankets?

- The installation guidelines for geotextiles used in erosion control blankets typically involve the following steps: 1. Site preparation: Ensure that the area where the erosion control blanket will be installed is properly graded and free of any debris or vegetation. 2. Unroll the geotextile: Start by unrolling the geotextile fabric along the slope or area where erosion control is needed. Make sure to overlap the fabric by the specified amount to ensure complete coverage. 3. Secure the fabric: Use stakes or landscape pins to secure the geotextile to the ground, especially at the edges and corners. This will prevent it from shifting or being displaced during installation or heavy rainfall. 4. Seam connection: If multiple rolls of geotextile fabric are required, ensure that they are properly overlapped and securely connected using a recommended seam connection method. This will ensure a continuous and seamless coverage. 5. Anchoring: In certain cases, additional anchoring may be required to provide extra stability. This can include using sandbags, rocks, or other suitable materials along the edges or across the surface of the geotextile fabric. 6. Vegetative cover: If the erosion control blanket is designed to support vegetation growth, follow the recommended guidelines for seed or plant installation. This may involve spreading seeds or planting live vegetation through the geotextile fabric. It is important to note that these guidelines may vary depending on the specific erosion control blanket and geotextile manufacturer, as well as the site and project requirements. It is always recommended to refer to the manufacturer's installation instructions and consult with a professional engineer or erosion control specialist for proper installation and best results.

- Q: How do geotextiles help with sediment retention in sediment basins?

- Geotextiles help with sediment retention in sediment basins by acting as a physical barrier that traps and holds sediment particles while allowing water to pass through. They prevent the escape of fine particles, reduce turbidity, and promote settling of sediments, thereby improving the overall effectiveness of sediment basins in sediment control and erosion prevention.

- Q: How do geotextiles help in slope stabilization?

- Geotextiles help in slope stabilization by providing reinforcement and erosion control. They are placed on slopes to prevent soil erosion and the movement of soil particles, effectively stabilizing the slope. The geotextiles act as a barrier, allowing water to pass through while retaining the soil in place. This helps to prevent landslides, soil erosion, and slope failure, ensuring the long-term stability and safety of the slope.

- Q: How are geotextiles different from other geosynthetic materials?

- Geotextiles are a type of geosynthetic material that is specifically designed for filtration and separation purposes in civil engineering applications. Unlike other geosynthetic materials such as geogrids or geomembranes, geotextiles are predominantly made of woven or non-woven fabric, which gives them excellent filtration and drainage properties. Additionally, geotextiles are more flexible and have higher tensile strength compared to other geosynthetics, making them suitable for a wide range of soil stabilization and erosion control applications.

- Q: Engineering geotextile non-woven fabrics where the cheapest can buy, where the wholesale market?

- Manufacturers need to add 8720 -

Send your message to us

Geotextil De Polipropileno Short Non-Woven Geotextile Fabric 300gsm for Railway-CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords