Geotextiles UK - Polyethylene HDPE Geotextile Membrane Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

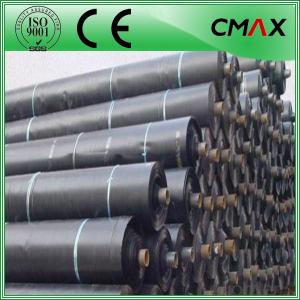

HDPE Geomembrane

Thickness: 1.0mm to 3.0mm

Roll Size: 4m-9m in width

roll length as design or client’s request

LDPE Geomembrane

Thickness: 0.1mm to 3.0mm

Roll Size: 4m-9m in width

roll length as design or client’s request

LLDPE Geomembrane

Thickness: 0.5mm to 3.0mm

Roll Size: 4m-9m in width

roll length as design or client’s request

Type:

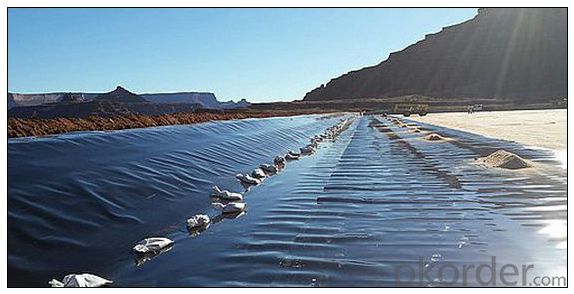

Waterproof Membrane

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

ISO

Sample:

Available

Color:

customized

width:

4m-9m

thickness:

1mm-3mm

length:

customized

material:

geotextile+HDPE membrane/geote

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: What are the advantages of using geotextiles in waste containment systems?

- Geotextiles offer several advantages in waste containment systems. Firstly, they act as a barrier, preventing the migration of contaminants from the waste site into the surrounding environment. Secondly, they provide stability and reinforcement to the waste containment structure, enhancing its strength and durability. Additionally, geotextiles facilitate proper drainage and filtration, allowing for the efficient removal of excess water and leachate. They also minimize soil erosion, which is crucial for long-term stability. Overall, geotextiles improve the performance and longevity of waste containment systems while minimizing environmental risks.

- Q: What are the specifications for geotextiles in sediment control projects?

- The specifications for geotextiles in sediment control projects typically include factors such as material type, weight, tensile strength, permeability, and durability. These specifications ensure that the geotextiles effectively prevent soil erosion, retain sediment, and allow for proper drainage in sediment control projects.

- Q: Are geotextiles resistant to acid degradation?

- Yes, geotextiles are generally resistant to acid degradation. They are designed to withstand various environmental conditions, including exposure to acids, making them suitable for applications where acid resistance is required.

- Q: Can geotextiles be used in coastal dune stabilization projects?

- Yes, geotextiles can be used in coastal dune stabilization projects. Geotextiles are often employed to reinforce and stabilize sand dunes by trapping and retaining sand particles, preventing erosion caused by wind and water. They can be used in various applications such as dune formation, dune restoration, and beach nourishment projects to enhance the natural protection of coastal areas and mitigate erosion.

- Q: Alteration of highway seepage control geotextile is generally placed in what position

- Apply to the grassroots level of water defense, the use of embedded, covered with thickness should not be less than 30CM, soil to be solid, to avoid uneven subsidence, cracks. Lap width should be greater than 15CM.

- Q: What equipment is geotextile equipment?

- This I do not how clear, and detailed you can go to Long Yun machinery manufacturers to see, his home is specialized in producing this equipment manufacturers, hoping to help you to adopt.

- Q: Geotextile detection frequency

- First according to customer requirements grams / square meters, thickness, width, with or without the use of chemical fiber requirements, proofing, and the proofing process parameters, including feed speed, other machines and other parameters of the speed record, Do twenty to ten meters, to test, if qualified, to do so, a lot of bulk, do a few days and then try to seize what the general geotextile manufacturers themselves to prepare several commonly used testing equipment,

- Q: The technical parameters of woven geotextile

- Test items / specifications 0400 Remarks breaking strength (longitudinal) KN / m ≥ 17. Breaking strength (horizontal) KN / m ≥ no special requirements by the meridional 0.7 / 1 longitudinal and transverse elongation at break% ≤ 25 vertical and horizontal trapezoidal torn Strength, KN ≥ 0.180.200.270.340.410.480.600.72 vertical and horizontal CBR top breaking strength, KN ≥ 1.41.62.43.24.04.86.07.5 equivalent aperture O95 (O95) mm0.07-0.5 vertical permeability coefficient cm / sK × (10-1-10-4) K = 1.0-9.9

- Q: Geotechnical deployment of aging detection of what indicators

- Material anti-aging performance testing, if the reality to consider, for too long, are generally used in the laboratory to accelerate the aging approach to consider. Aging the concept of aging is a big concept. Refers to the material in the external environment under the influence of time changes. Environmental effects are multifaceted, the role of light, the role of temperature, a chemical role, the role of micro-organisms and so on. Now generally referred to as aging, refers to the light aging. Light aging, refers to the material in a certain light exposure after a certain period of time after the performance of the material changes. The most commonly used indicator for photoaging is the strength retention of the material. That is, the ratio of the strength that remains after the light is retained.

- Q: What are the factors to consider when designing geotextile-reinforced slopes?

- When designing geotextile-reinforced slopes, several factors need to be considered. These include the type and strength of geotextile to be used, the slope angle and height, soil properties, expected loads and stresses, water drainage and erosion control measures, construction methods, and long-term performance requirements. Additionally, site-specific conditions such as climate, vegetation, and nearby structures should also be taken into account. Proper consideration of these factors ensures a safe and stable design that effectively mitigates slope failures and erosion.

Send your message to us

Geotextiles UK - Polyethylene HDPE Geotextile Membrane Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords