Polyethylene Fiberglass High Strength Geogrid Geotextile USA Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

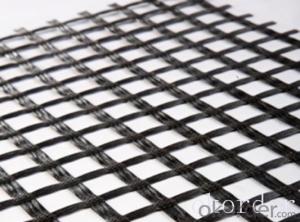

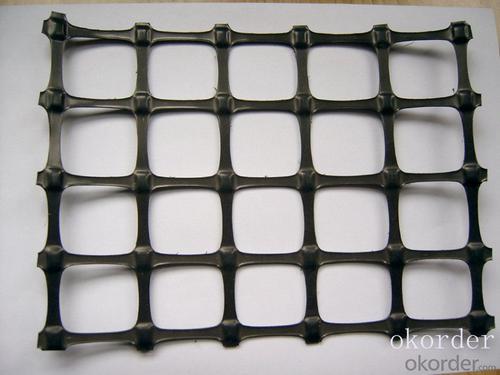

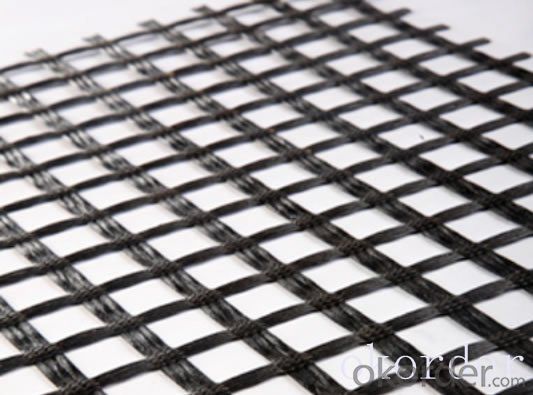

Biaxial

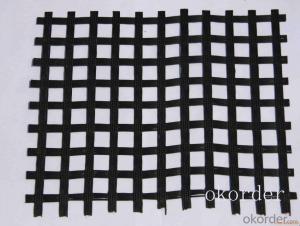

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

A geogrid is geosynthetic material used to reinforce soils and similar materials. Geogrids are commonly used to reinforce retaining walls, as well as subbases or subsoils below roads or structures. Soils pull apart under tension. Compared to soil, geogrids are strong in tension. This fact allows them to transfer forces to a larger area of soil than would otherwise be the case.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in waste containment systems?

- Yes, geotextiles can be used in waste containment systems. Geotextiles are commonly used as liners or covers in landfill sites to prevent the migration of hazardous substances into the surrounding environment. They provide a barrier to contain waste materials, prevent erosion, and promote filtration and drainage.

- Q: Can geotextiles be used in mining and landfill closure applications?

- Yes, geotextiles can be used in mining and landfill closure applications. They serve as a protective barrier to prevent soil erosion, control sedimentation, and provide filtration and separation functions. Geotextiles also help in stabilizing slopes, reinforcing structures, and reducing the potential for contamination in mining and landfill closure sites.

- Q: Geotextile longitudinal and lateral elongation gap is too much how to adjust

- 1. The elongation at break of the geotextile is divided into longitudinal elongation at break and transverse elongation at break. Generally speaking, the elongation at longitudinal and transverse faults is not very different. GB GB / T-2008 standard requirements geotextile longitudinal and lateral elongation between 20% -100% are qualified. 2. Longitudinal transverse fracture elongation gap is too large, you can check the mixing hopper, carding machine is mixed evenly, combing evenly. 3. Acupuncture machine too fast or too high acupuncture may lead to geotextile longitudinal and transverse elongation gap, you can try to debug the speed of the next needle machine. 4. Appropriate to add some industrial oil can enhance the geotextile rupture strength, and elongation at break.

- Q: Does geotextile affect water purification?

- Do not know what you use after the purification of water, if not drinking water, I think it will not affect the water quality, the general purpose of water purification, geotextile will not affect, because the geotextile material is polyester or polypropylene, In the chemical nature of relatively stable, no changes in room temperature conditions, so there will not be any impact on water quality

- Q: How do geotextiles contribute to the performance of geocell systems?

- Geotextiles play a crucial role in enhancing the performance of geocell systems. They are installed within the geocell walls and act as a stabilizing agent by providing reinforcement and preventing soil migration. Geotextiles distribute the load evenly, increase the overall strength of the system, and improve the overall stability and longevity of the geocell structure. Additionally, geotextiles can also act as a filtration layer, allowing water to pass through while preventing soil particles from clogging the system, thereby maintaining its efficiency and functionality.

- Q: Geotextile puncture test standard

- Staple stitch filament piercing filament woven weaving

- Q: Composite geotextile have what model specifications

- Composite geomembrane; mass per unit area g / m000 Membrane thickness mm0.25-0.350.3-0.5 breaking strength KN / m57.510.012.014.016.018.0 vertical and horizontal elongation at break% 30-100CBR breaking strength KN ≥ 1.11 . 51.92.22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

- Q: How are geotextiles used in agricultural applications?

- Geotextiles are used in agricultural applications to provide erosion control, promote soil stabilization, and enhance draining capabilities. They are often used in the construction of retaining walls, terraces, and embankments to prevent soil erosion and maintain the integrity of the structures. Additionally, geotextiles can be used as a protective layer over the soil, allowing water to pass through while preventing weed growth and conserving moisture.

- Q: Can geotextiles be used in the protection of groundwater sources?

- Yes, geotextiles can be used in the protection of groundwater sources. Geotextiles are permeable fabrics that can effectively filter out impurities and prevent soil erosion. By installing geotextiles in areas where groundwater sources are vulnerable to contamination or excessive sedimentation, they can act as a barrier, allowing water to pass through while trapping pollutants and preventing them from reaching the groundwater. This helps to maintain the quality and purity of groundwater sources, ensuring their long-term protection.

- Q: Do you need to use geotextile for construction site? Mainly used where?

- What do you want to specify? In what position. Are generally used in waterproof engineering.

Send your message to us

Polyethylene Fiberglass High Strength Geogrid Geotextile USA Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords