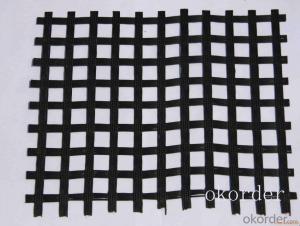

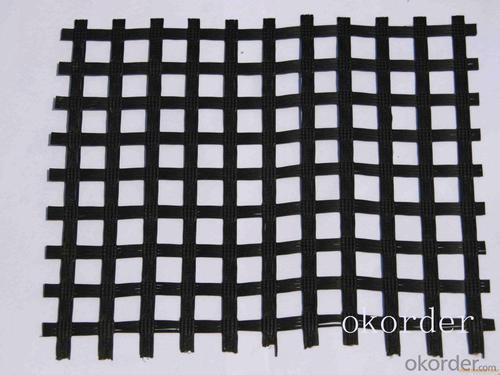

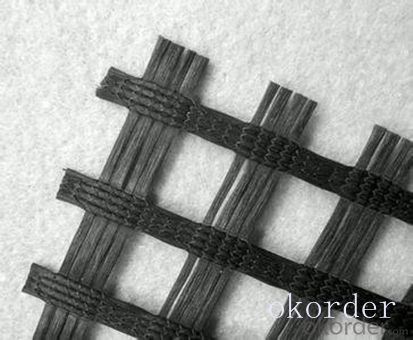

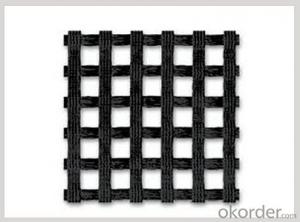

High Strength Fiberglass Geogrid Polyethylene Geotextile for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

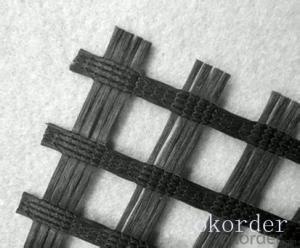

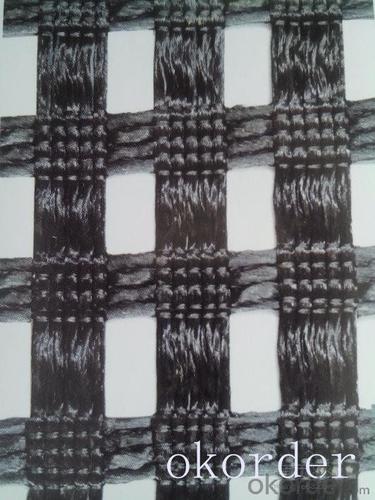

Product Introduction

We offer a unique line of extruded polymer grids for protecting and reinforcing grassed vehicular areas. Reinforcement Mesh is a tough extruded polymer grid for reinforcing grassed areas used by vehicles and pedestrians. We are inert to biological degradation and resistant to creep, strain and naturally found chemicals.steel-plastic composite geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

PP geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KN

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is the role of geosynthetics in the highway?

- Geosynthetics a lot of geogrid, geotextile which is specific

- Q: In the river within the construction of flexible piping can use geotextile to do anti-floating measures

- Yes, I am specialized in producing the installation

- Q: How do geotextiles help in the construction of ponds and lakes?

- Geotextiles help in the construction of ponds and lakes by providing reinforcement, filtration, and erosion control. They act as a barrier between the soil and water, preventing soil erosion and promoting stability. Geotextiles also help in filtering out any fine particles or contaminants, ensuring clean and clear water. Additionally, they enhance the strength and durability of the pond or lake structure, increasing its longevity and resistance to wear and tear.

- Q: Can geotextiles be used in tunnel construction?

- Yes, geotextiles can be used in tunnel construction. Geotextiles are often employed as a reinforcement material to enhance the stability and strength of the tunnel lining. They can also be used as a separation layer between the tunnel lining and the surrounding soil, preventing the mixing of different materials and ensuring the overall integrity of the tunnel structure. Additionally, geotextiles can provide filtration and drainage functions, helping to control water flow and mitigate potential issues such as soil erosion or groundwater seepage. Overall, geotextiles play a crucial role in tunnel construction by improving the performance and durability of the tunnel infrastructure.

- Q: What is the filament single-sided singeing geotextile

- Filament single-sided singeing geotextile is through a series of hot-rolling process will filament geotextile side of the filament fiber roll hot filament geotextile surface of the unity, thereby increasing the filament geotextile non-slip, anti- Tear resistance. Filament singeing geotextile is generally used for landfill, tailings and other projects with rough surface geomembrane with the use of friction coefficient to increase and improve anti-skid performance. Filament single-sided singeing geotextile is the first production of finished filament geotextile, and then through the professional equipment for single-sided singeing.

- Q: What is the geotextile material?

- Production of geotextile raw materials are: polyester staple fiber, polypropylene staple fiber, polyester filament, PP flat wire and so on

- Q: Are geotextiles suitable for use in seismic zones?

- Yes, geotextiles are suitable for use in seismic zones. Geotextiles have been proven to provide effective soil stabilization, erosion control, and reinforcement in areas prone to seismic activity. They can help mitigate soil liquefaction, slope instability, and ground settlement issues, making them a suitable choice for construction projects in seismic zones.

- Q: How do geotextiles contribute to sediment control?

- Geotextiles contribute to sediment control by acting as a barrier that prevents soil erosion and controls sediment movement. They are used in various applications such as erosion control blankets, sediment retention ponds, and silt fences, effectively trapping sediments while allowing water to pass through, reducing the risk of sediment runoff and contamination of water bodies.

- Q: Basement roof cover soil thickness and geotextile shop in what position,

- The size of the thickness of the roof cover of the basement garage is in the specification of the air defense design

- Q: Will the geotechnical cloth used for highway engineering, geogrid raw materials, routine testing items, parameters which?

- Geotextile main inspection items are: ① Tensile strength: In the tensile test, the specimen until the fracture until the maximum tensile stress is the tensile strength, known in the academic sense of tensile strength. ② elongation: elongation, that is, the percentage of the ratio of the total deformation to the length of the original gauge after the tensile fracture of the specimen. ③ tear strength: it is a thin film or thin film tear resistance of a test method defined in a term. This method is a tear test performed on a special testing machine with a specimen with a predetermined gap. ④ bursting strength ⑤ thickness ⑥ per unit area quality ⑦ permeability coefficient: permeability coefficient, also known as hydraulic conductivity. In an isotropic medium, it is defined as the unit flow rate per unit of hydraulic gradient, indicating the ease with which the fluid passes through the pore skeleton. Geogrids include: appearance, physical properties (including: mass per unit area, amplitude measurement, mesh size determination); mechanical properties (including: strip tensile test, joint / seam wide strip tensile test, sticky Solder joints)

Send your message to us

High Strength Fiberglass Geogrid Polyethylene Geotextile for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords