Geotextile Fabric Nz for Railway Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Instruction of Non-woven Geotextile for Railway Construction:

Geotextile is a non-woven product manufactured by combinining synthetic short yarns mechanically by using needling method. Non-woven geotextile has no woof and warp. Strength is achieved by combining yarns and applying thermal process. Geotextile felt is a permeable textile product which can be used with basic elements or with any material related with soil, running ground or geotechnic engineering.

Usuage Area of Non-woven Geotextile for Railway Construction:

Used in motorways, sport facilities, tunnels and underground facilities, art buildings, underground, agricultural areas, garden terraces, airports, mining fields, railways, solid waste storage areas, irrigation channels and reservoirs, shore protection and isolation areas; as a reinforcement against cracks between insulation layers; as a separator between waterproofing and thermal insulation layers; to protect insulation; to drain excess water; to prevent drainage pipes from plugging by wrapping them around; to avoid sinking and in many other applications.

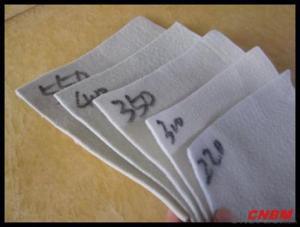

Technical Specifications of Non-woven Geotextile for Railway Construction:

Weight | TS EN ISO 9864 | gr/m² | 150 | 200 | 250 | 300 | 350 | 400 | 500 |

Thickness (at 2 kPa) | TS EN ISO 9863-1 | mm | 1,2 | 1,4 | 1,7 | 1,9 | 2,2 | 2,5 | 3,2 |

Tensile Strength (MD - CMD) | TS EN ISO 10319 | kN/m | 3 | 5 | 7 | 9 | 11 | 13 | 17 |

4 | 7 | 9 | 11 | 13 | 15 | 19 | |||

Elongation at break | TS EN ISO 10319 | % | 50-80 | ||||||

Static Puncture Test | TS EN ISO 12236 | N | 800 | 1200 | 1500 | 1800 | 2000 | 2200 | 3000 |

Dynamic Puncture Test | TS EN ISO 13433 | mm | 35 | 30 | 28 | 26 | 24 | 22 | 16 |

Permeability | TS EN ISO 11058 | l/m²s m/s | 110 0,110 | 100 0,100 | 90 0,090 | 80 0,080 | 70 0,070 | 60 0,060 | 40 0,040 |

Apparent Opening Size | TS EN ISO 12956 | mm | 0.16 | 0.15 | 0.14 | 0.13 | 0.13 | 0.12 | 0.11 |

Advantages of Non-woven Geotextile for Railway Construction:

Thanks to thermal process, more strength and less elongation is achieved with the same weight.

Requires smaller storage area.

Can be manufactured up to a width of 6 meters, leading to less loss of material.

Both white and tinted varieties of ge0textile are manufactured from 100% pure yarn. No recycled material is used.

Products can be manufactured with surface weight ranging from 50 gr/m2 to 1000 gr/m2.

Application of Non-woven Geotextile for Railway Construction:

- in liquid bituminous insulation applications, it is used as a reinforcement between layers and avoids cracks.

- it prevents cracks found on the surface from moving onto insulation surface.

- it protects bituminous membrane or geomembrane applications in foundations.

- it is used as a separator between waterproofing and thermal insulation layers.

- it is used as a separator between thermal insulation and protection layers.

- It is wrapped around drainage pipes in foundations and it is used as a filter layer in terrace gardens.

- It is used in applications designed to withdraw pressure under road coatings.

- Q: How do geotextiles improve the performance of slopes?

- Geotextiles improve the performance of slopes by providing erosion control, stabilization, and reinforcement. These synthetic fabrics are installed between the soil layers of the slope, acting as a barrier to prevent soil movement and erosion caused by water flow or wind. Geotextiles also enhance the overall stability of the slope by improving soil drainage, reducing pore water pressure, and increasing soil strength.

- Q: Can geotextiles be used in drainage applications?

- Yes, geotextiles can be used in drainage applications. They are commonly used to improve the performance and longevity of drainage systems by preventing soil erosion, filtering out fine particles, and promoting water flow. Geotextiles can be placed in various drainage applications such as road construction, agricultural drainage, landfills, and erosion control to enhance their effectiveness and efficiency.

- Q: Is the polyester nonwoven fabric geotextile?

- Not geotextile. Polyester non-woven fabrics: mainly used for construction, roof waterproof as a base cloth, attached to the above sand, cement, etc., to prevent the role of sand leakage. Nonwovens are often used in construction and are a measure to prevent cracks. Geotextile manufacturers, for your answer

- Q: How do geotextiles help with reinforcement of geotextile tubes?

- Geotextiles help with the reinforcement of geotextile tubes by providing stability and strength. They act as a barrier, preventing soil erosion and maintaining the shape and integrity of the tube. The geotextile acts as a filter, allowing water to pass through while retaining soil particles, which helps in soil consolidation and prevents the tube from collapsing. Additionally, geotextiles distribute stress evenly across the tube, enhancing its load-bearing capacity and overall performance.

- Q: What are the routine tests of geotextile geotextiles?

- The geocell is mainly the tensile strength of the tensile test lattice sheet and the peel strength of the solder joint. Geotextile according to the specific circumstances of the use of the project 1. Roadbed reinforcement, isolation is mainly tensile test tensile strength, elongation, tear strength and CBR top broken 2. Filter with the addition of these also use the vibrating screen test Equivalent pore size 3. Maintenance is mainly weight, thickness and strength

- Q: What are the materials used for spinning geotextiles?

- Geotextile is divided into several, filament spunbond acupuncture non-woven geotextile, this is the name suggests is to use silk to do; staple acupuncture non-woven geotextile, this is the use of fiber to do;

- Q: Geotextile longitudinal and lateral elongation gap is too much how to adjust

- 1. The elongation at break of the geotextile is divided into longitudinal elongation at break and transverse elongation at break. Generally speaking, the elongation at longitudinal and transverse faults is not very different. GB GB / T-2008 standard requirements geotextile longitudinal and lateral elongation between 20% -100% are qualified. 2. Longitudinal transverse fracture elongation gap is too large, you can check the mixing hopper, carding machine is mixed evenly, combing evenly. 3. Acupuncture machine too fast or too high acupuncture may lead to geotextile longitudinal and transverse elongation gap, you can try to debug the speed of the next needle machine. 4. Appropriate to add some industrial oil can enhance the geotextile rupture strength, and elongation at break.

- Q: What is a polyester filament geotextile? Polyester filament geotextile

- In addition to a good mechanical energy, but also has a good vertical and horizontal drainage and good extension of energy and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, also has a wide range of pore size, tortuous pore distribution, excellent permeability and filtration can be polyester filament geotextile purposes: water conservancy project dam and slope protection filter, channel isolation, seepage; Airport runway foundation isolation, filter, drainage, soil slope, retaining wall and road reinforcement, drainage; port engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile Has been widely used in the field of infrastructure construction, and gradually applied to a wider range of areas. Polyester filament geotextile technical parameter table (GBT-1998): No. Remarks 1 unit area mass deviation% -6-6-6-5-5-5-5-5-4-4-42 thickness, mm ≥ 553 Width deviation% -054 breaking strength KNM ≥ vertical and horizontal 5 elongation at break% 40-806CBR breaking strength KN ≥ 707 equivalent aperture 090, mm007-02

- Q: How do geotextiles contribute to soil moisture retention?

- Geotextiles contribute to soil moisture retention by acting as a barrier that prevents water evaporation from the soil surface, while still allowing water to pass through and be absorbed by the soil. This helps to maintain a higher level of soil moisture, reducing water loss and promoting healthier plant growth. Additionally, geotextiles can also prevent soil erosion, which further aids in retaining soil moisture.

- Q: Can geotexters cover grass seeds?

- Yes, a lot of lawns are covered, but with dozens of grams of geotextiles are used

Send your message to us

Geotextile Fabric Nz for Railway Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords