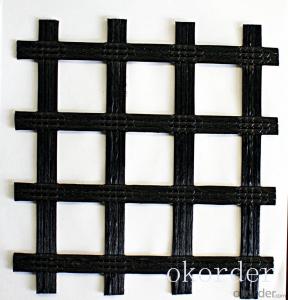

High Tensile Strength Fiberglass Geogrids Price Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

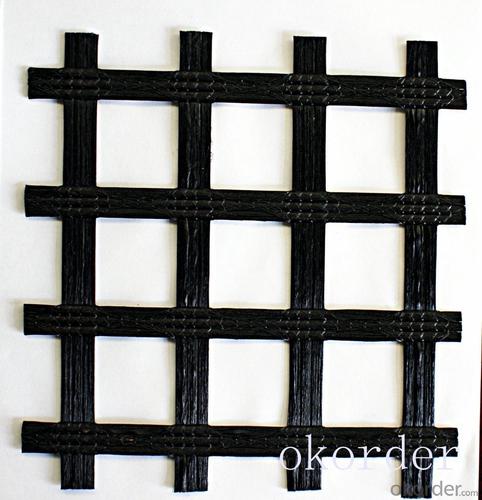

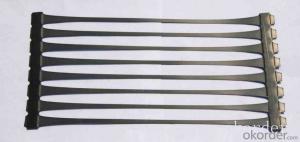

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Geogrid protects channel slopes, provides resistance and stability, protecting this object from erosion. Additional advantage is drainage along channels. Geogrid application considerably reduces losses, connected with fall of ground, landslides and deformation of slopes.Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

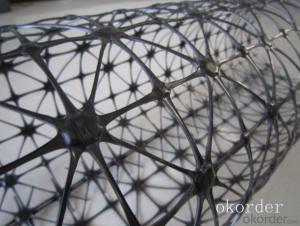

A: Yes, please check the pictures:

- Q: Can geogrids be used in landfill applications?

- Yes, geogrids can be used in landfill applications. Geogrids are commonly used in landfill construction to enhance stability, increase load-bearing capacity, and prevent soil erosion. They help to distribute the load more evenly, improve the overall structural integrity, and provide additional support to the landfill liner system.

- Q: Are geogrids suitable for use in seismic zones?

- Yes, geogrids are suitable for use in seismic zones. Geogrids are engineered materials that provide reinforcement and stability to soil structures. They can help improve the performance of geotechnical structures and mitigate the impact of seismic events by enhancing soil compaction, reducing soil settlement, and increasing overall stability. Additionally, geogrids can help in the distribution of seismic forces and reduce the risk of slope failure or soil liquefaction, making them a suitable choice for use in seismic zones.

- Q: Are geogrids suitable for use in expansive soil conditions?

- Yes, geogrids are suitable for use in expansive soil conditions. Geogrids are designed to improve soil stability and prevent soil movement, making them an effective solution for managing expansive soils. By reinforcing the soil, geogrids help to reduce the potential for soil swelling and contraction, which can cause damage to structures.

- Q: Physical characteristics of geogrid construction method

- 2, check the geogrid reinforced asphalt pavement or cement: Geogrid laying layer at the bottom of asphalt or cement, can reduce rutting depth, prolong the fatigue life of the pavement, but also can reduce the asphalt or cement pavement thickness, in order to save costs.3, one-way geogrid for reinforcing the dam and road slope and retaining wall: the traditional embankment especially filling high embankment filling and often need to shoulder edge easy compaction, resulting in slope rainwater invasion, collapse phenomenon, at the same time with a gentle slope, covers an area of large, retaining wall have the same problem with Geogrid embankment slope or retaining wall reinforcement can be reduced by two points a area, prolong service life, reduce the cost of 20 - 50%.4, one-way geogrid to reinforce the River seawall: made of stone cage, with the grid and use, prevent the dam washed collapse, stone cage is permeable and can reduce the impact of the waves, prolong the life of the dam, save manpower, shorten the construction period.5, one-way geogrid for processing landfills: Geogrid and other synthetic materials using a combination of Soil Treatment Landfill, can effectively solve the problem of gas emissions derived from the uneven settlement of foundation, and can improve the landfill to maximize storage capacity.6, one-way geogrid special purpose: low temperature resistance. Low temperature resistance of geogrid Lianyi, at - 45 C and 50 C - repeated 200 cycles, the performance indexes meet the requirements, and has been applied to the test of the Qinghai Tibet railway, the North less ice permafrost and ice rich permafrost and ice rich permafrost bad geology.

- Q: What is the recommended spacing between geogrid layers?

- The recommended spacing between geogrid layers depends on several factors, including the type of geogrid being used, the intended application, and the soil conditions. It is best to consult the manufacturer's specifications or a geotechnical engineer for specific recommendations. However, in general, a spacing of 2 to 3 feet between geogrid layers is common for stabilization and reinforcement purposes.

- Q: Unidirectional tensile plastic geogrid manufacturers which good

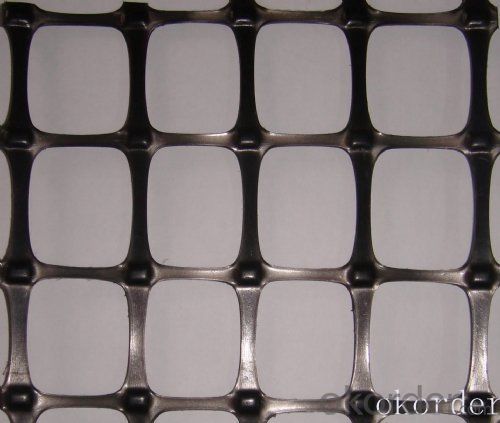

- (1) the plastic geogrid plastic geogrid is a kind of polymer material with square or rectangular shape which is formed by stretching, and it can be used as one kind of unidirectional stretching and biaxial stretching according to the different direction of stretching in the manufacturing process. The utility model is punched on the extruded polymer plate (raw material is polypropylene or high-density polyethylene), and then directionally stretched under the heating condition

- Q: Can geogrids be used in soil reinforcement for load-bearing platforms?

- Yes, geogrids can be effectively used in soil reinforcement for load-bearing platforms. Geogrids are engineered materials that provide soil stabilization and improve the load-bearing capacity of soils. They are typically made of high-strength polymers and have a grid-like structure that interlocks with the soil particles, creating a stable foundation. Geogrids distribute the applied loads more evenly, reducing the potential for soil settlement and enhancing the overall stability of load-bearing platforms.

- Q: How do geogrids enhance the performance of flexible retaining structures?

- Geogrids enhance the performance of flexible retaining structures by providing reinforcement and stability to the soil. They distribute the loads more evenly, reducing the stress on the structure and increasing its overall strength. Geogrids also prevent soil erosion and improve drainage, ensuring the long-term integrity and durability of the retaining structure.

- Q: Application and effect of steel plastic geogrid

- When the soft ground treatment when the roadbed filling height of 3-4 meters or between the Luqiao Union, to prevent uneven settlement.Widening of old road to prevent longitudinal cracks in the old and new subgrade.

- Q: What are the applications of geogrids?

- Geogrids have a wide range of applications in civil engineering and construction projects. They are commonly used for soil stabilization, reinforcement of slopes and retaining walls, erosion control, and pavement reinforcement. Geogrids help enhance the strength and stability of soil structures, prevent soil erosion, and provide long-lasting solutions for various geotechnical challenges.

Send your message to us

High Tensile Strength Fiberglass Geogrids Price Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords