Classe Géotextile Woven PP Earthwork for Road and Railway

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Type: | Geotextiles | Place of Origin: | Shan Dong , China (Mainland) | Brand Name: | CMAX woven geotextile |

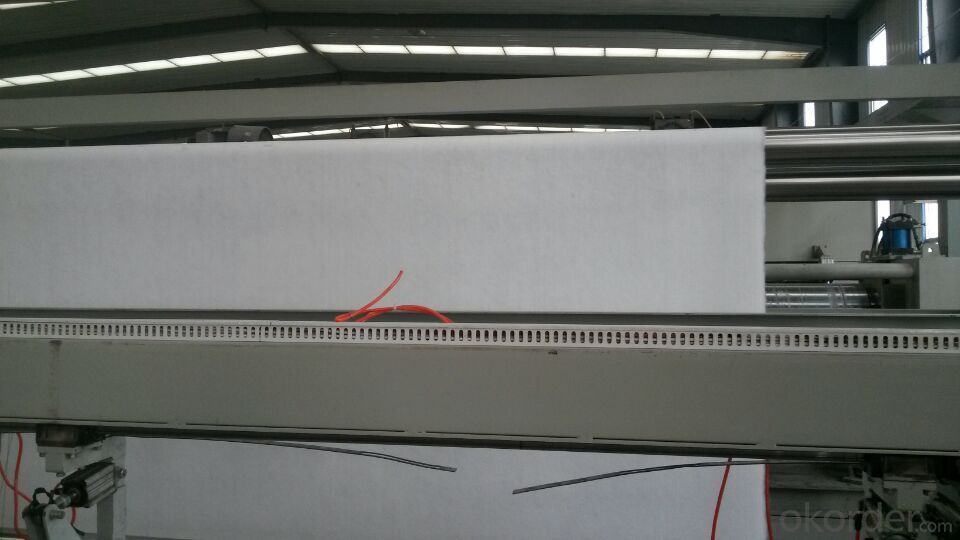

Model Number: | High Strength | Geotextile Type: | Woven Geotextiles | Color: | White |

Strength: | 200/50KN/M | Elongation: | <15% | Width: | 3.6m |

Roll length: | 200m |

Packaging & Delivery

Packaging Details: | Woven geotextile package:Rolled with cardboard core, wrapped with PE film and PP tape fabric |

Delivery Detail: | one 40'HQcontainer within 15 working days |

Specifications

our woven geotextile have superior properties for filtration, separation, reinforcement, erosion control

1.About Us

Company Profile :

We have more than 25 years experience in development & manufacture synthetics like woven geotextile , geotube,silt curtain,concrete filling mattress,pile jacket and industrial

fabric. Depending on our full set production line, well equipped laboratory, cooperation with

institute& college and experienced employees, we havesuccessfully developed and

consolidated domestic and foreign market.

2.Products

Woven geotextile :

Made from polypropylene and or polyester fibers, manufactured with high tensile strength and low elongation, our woven geotextiles have superior properties for filtration, separation, reinforcement, erosion control and drainage. We are leader in providing woven geotextiles for a variety of civil and environmental applications including highways, port facilities, reservoir, transport construction, waste and chemical management ,subgrade engineering, coast reclamation works, peninsula shoal engineering.

Properties of Multifilament Woven Geotextile

Metric and British conversions:

1kn/m------around68.57lbs/ft 1oz/yd2---around 33.9g/m2 1m------around 3.3ft

Physical properties | Test method | Unit | Typical Value | ||||||||||

Material | Polypropylene/PP | ||||||||||||

Unit Weight | ASTM D 5261 | g/m2 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1300 | ||

Color | White | ||||||||||||

Tensile Strength at break MD | ASTM D 4595 | KN/M >= | 50 | 75 | 100 | 130 | 160 | 180 | 200 | 230 | 360 | ||

Tensile Strength at break CD | ASTM D 4595 | KN/M >= | 35 | 52 | 70 | 90 | 112 | 126 | 140 | 160 | 280 | ||

Elongation at break MD | ASTM D 4595 | % <= | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | ||

Elongation at break CD | ASTM D 4595 | % <= | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||

CBR Puncture Strength | ASTM D 6241 | KN | 4 | 6.9 | 10.5 | 14 | 18 | 20.5 | 23 | 24 | 28 | ||

Tear Strength | ASTM D 4533 | KN | 0.6 | 1 | 1.3 | 1.55 | 1.9 | 2 | 2.2 | 2.3 | 3.2 | ||

Permitivity | ASTM D 4491 | S-1 | 0.01-0.8 | ||||||||||

Pore opening size O90 | ASTM D 4751 | mm | 0.06-0.7 | ||||||||||

Width: max 3.8m, standard 3.6m. Other colors available. | |||||||||||||

Physical properties | Test method | Unit | Typical Value | |||||||

Material | Polyester/PET | |||||||||

Color | White | |||||||||

Tensile Strength at break MD | ASTM D 4595 | KN/M | 100 | 150 | 150 | 200 | 400 | 300 | 500 | 1000 |

Tensile Strength at break CD | ASTM D 4595 | KN/M | 50 | 50 | 150 | 50 | 50 | 300 | 100 | 50 |

Elongation at break MD | ASTM D 4595 | % | <=15 | |||||||

Elongation at break CD | ASTM D 4595 | % | <=15 | |||||||

Permitivity | ASTM D 4491 | S-1 | 0.01-0.8 | |||||||

Pore opening size O90 | ASTM D 4751 | mm | 0.06-0.7 | |||||||

- Q: What are the long-term performance expectations for geotextile installations?

- The long-term performance expectations for geotextile installations vary depending on factors such as the specific application, the quality of the geotextile material, and the environmental conditions. However, in general, geotextile installations are designed to provide durable and reliable performance for extended periods, typically ranging from 20 to 50 years. Regular maintenance and monitoring can help ensure that geotextile installations continue to perform effectively over the long term.

- Q: Can geotextiles be used in landfill construction?

- Yes, geotextiles can be used in landfill construction. They are often used as a barrier or liner material to separate the waste from the underlying soil and prevent leachate from contaminating the surrounding environment. Geotextiles can also be used to reinforce the landfill slopes and prevent erosion.

- Q: Geotextile how to do on-site measurement

- Geotextile is calculated by the square, you only need to measure a long, wide, calculate the area will be able to know how much geotextile, and hope to help you!

- Q: Can geotextiles be used for reinforcement of paved surfaces?

- Yes, geotextiles can be used for the reinforcement of paved surfaces. Geotextiles are commonly deployed underneath the asphalt or concrete layers of paved surfaces to enhance their strength, stability, and durability. They help distribute the load over a larger area, prevent cracking and rutting, and control the growth of vegetation. Additionally, geotextiles can minimize the potential for reflective cracking and provide separation between different layers, enhancing the overall performance of paved surfaces.

- Q: How are geotextiles tested for permeability?

- Geotextiles are tested for permeability using standard laboratory methods, such as the constant head or falling head permeability tests. These tests involve measuring the flow of water through the geotextile under controlled conditions, allowing engineers to determine its permeability and suitability for various applications.

- Q: River slope protection geotextile unit area quality is generally how much

- Geotextile width of 2-6 meters. Length can be customized according to the requirements, generally 100g - 1000g specifications, per square meter. I am specializing in the production of geotextile materials, welcome you, hope to adopt!

- Q: What are the applications of geotextiles in landscaping?

- Geotextiles have various applications in landscaping, including erosion control, soil stabilization, and weed suppression. They can be used to prevent soil erosion on slopes, retain soil in embankments, and enhance the stability of retaining walls. Geotextiles also act as a barrier to prevent weed growth, reducing the need for herbicides. Additionally, these textiles can be employed in drainage systems to improve water filtration and prevent soil compaction. Overall, geotextiles provide valuable solutions for improving the sustainability and longevity of landscaping projects.

- Q: Such as the title, the drawings are written on the weaving geotextile, the list is written on the blended geotextile cloth laying / 120g / m2 weaving geotextile, who can tell ah !!!!!!!!!! Urgent more

- Or geotextile ah

- Q: Ask geotextile factory in the use of geotextile aperture detector detection method which?

- Hello, geotextile detection method in GB / T and GB / T geotextile aperture in the introduction, you can look at these two standards. The first is geotextile pore size detection wet sieve method, the second is geotextile aperture detection dry sieve method. As the name suggests the first of these two methods is the participation of water, the other is basically the same, are placed in a single layer of geotextile standard small particles, through the vibration to detect the size of the leakage of particles to determine the geotextile pore size size. The difference is that the first standard in the need for continuous water on the particles, so the calculation method are also different. Specific detailed distinctions You can search these two criteria separately.

- Q: How do geotextiles contribute to soil stabilization in mining areas?

- Geotextiles contribute to soil stabilization in mining areas by providing a strong and durable reinforcement layer. They help prevent soil erosion, control sediment runoff, and improve the stability of slopes and embankments. Geotextiles act as a barrier, distributing loads and reducing the potential for soil movement. Additionally, they promote better drainage, allowing water to flow through the soil while retaining its structural integrity. Overall, geotextiles play a crucial role in maintaining the stability and safety of mining areas by enhancing the resilience of the soil.

Send your message to us

Classe Géotextile Woven PP Earthwork for Road and Railway

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords