Geotextile Boise Asphalt Reinforcement Fiberglass Geogrid Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

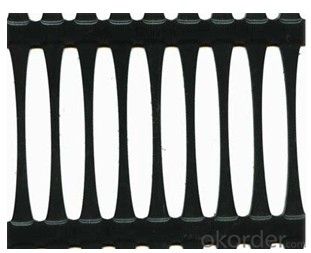

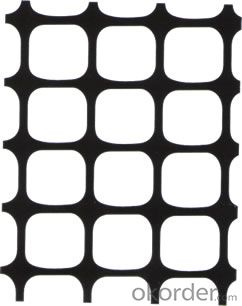

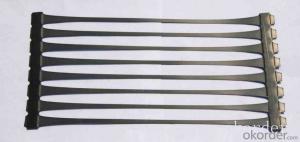

Description Of Asphalt Reinforcement Fiberglass Geogrid:

Biaxial Geogrid is made by polypropylene(PP) as the raw material, through special extruded & biaxial.

Main Features of Asphalt Reinforcement Fiberglass Geogrid:

1. High tensile strength in warp and across directions

2. Low Elongation

3. High flexibility

4. High and low temperature resistance

Specifications of Asphalt Reinforcement Fiberglass Geogrid:

Short fiber nonwoven geotextile technical data

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

Applications of Asphalt Reinforcement Fiberglass Geogrid:

PP biaxial geogrids can be used to enhancement of permanent bearable soft including highway and railways embankment, slopes, tunnel, airport, parking lots, loaded pier and ground and their main usage are as follows:

1. enhance the bearing capacity fo road foundation and extend the duration of highway.

2. prevent highway surface from collapse, crack and being dirty.

3. be convenient for construction timesaving and cut down the cost of maintenance.

4. prevent tunel from crack occuring

5. further solidity slopes to proof water and soil from losses

6. reduce the surface thickness of the ground.

7. consolidate the net for growing grass on the slopes so as to stabilization surrounding virescence.

8. be used for artificial top net of mines instead of metal ones. It is of flame retardant and antistatics

IMages of Asphalt Reinforcement Fiberglass Geogrid:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What is geomembrane geomembrane, composite geomembrane

- Anti-seepage drainage of the site ah Geomembrane ah

- Q: What are the different factors to consider for geotextile selection in agricultural applications?

- Some of the different factors to consider for geotextile selection in agricultural applications include the required strength and durability of the geotextile, the type and weight of the soil, the presence of chemicals or contaminants, the desired permeability and drainage capacity, as well as the specific application and intended use of the geotextile. Additionally, factors such as installation requirements, cost-effectiveness, and environmental considerations should also be taken into account.

- Q: Application of composite geotextile

- Water conservancy projects: seawall, river embankment, lake embankment project; reservoir reinforcement project; reclamation project; flood control and rescue. Highway and railway engineering: soft foundation reinforcement treatment; slope protection; road anti-reflective crack structure layer; drainage system; green isolation zone. Electrical engineering: nuclear power plant basic engineering; thermal ash dam project; hydropower project.

- Q: What are the potential drawbacks of using geotextiles?

- Some potential drawbacks of using geotextiles include limited durability in harsh environmental conditions, potential for clogging or reduced permeability over time, and the need for proper installation and maintenance to ensure effectiveness. Additionally, geotextiles may have limited effectiveness in certain applications or soil types, and their cost can be higher compared to traditional construction materials.

- Q: What are the advantages of using geotextiles in landfill lining systems?

- There are several advantages of using geotextiles in landfill lining systems. Firstly, geotextiles act as a barrier that prevents the migration of contaminants from the landfill into the surrounding environment. This helps to protect groundwater and nearby ecosystems from contamination. Secondly, geotextiles enhance the stability and integrity of the landfill lining system. They provide reinforcement and help to distribute the load evenly, which reduces the risk of structural failure. Additionally, geotextiles have excellent filtration properties. They allow for the efficient drainage of leachate, which is the liquid that is generated as waste decomposes. This helps to prevent the buildup of pressure within the landfill and reduces the risk of leachate seeping into surrounding areas. Furthermore, geotextiles are durable and resistant to degradation, ensuring the longevity of the landfill lining system. They are also lightweight and easy to install, which can save time and costs during construction. Overall, the use of geotextiles in landfill lining systems provides numerous benefits in terms of environmental protection, structural integrity, drainage efficiency, and cost-effectiveness.

- Q: What are the environmental benefits of using geotextiles?

- Geotextiles offer several environmental benefits, such as erosion control by stabilizing soil and preventing sediment runoff, enhancing water filtration and drainage systems, reducing the need for chemical herbicides and pesticides, and promoting the growth of vegetation. Additionally, they can help in the restoration and protection of ecosystems, reduce construction waste by extending the lifespan of infrastructure, and minimize the use of non-renewable materials like aggregates.

- Q: Why do you shop the geotextile during the construction of the road

- Huazhi geotechnical materials manufacturers to answer

- Q: Where to sell black geotextile prices

- Those who produce geotextile manufacturers are selling black geotextile. Black geotextile according to the use of a lot of specifications, the price difference is very large. The weight per square meter between about 50-1000g grams, the weight of different unit price is different, the inquiry directly asked how much money per ton. According to the use of distinction between the current market price per ton price between 5,000 yuan - yuan. For the conservation, isolation, insulation of the geotextile the cheapest. In the 5000 yuan / ton between. For the filter, soft base treatment, slope protection, reinforced decoration, and other purposes of the black geotextile most expensive in - yuan / ton. The same black color, but different uses, production processes and production costs are not the same.

- Q: How are geotextiles tested for strength and durability?

- Geotextiles are tested for strength and durability through various methods such as tensile strength tests, puncture resistance tests, tear strength tests, and abrasion resistance tests. These tests involve subjecting the geotextile to controlled forces and conditions to determine its ability to withstand different types of stresses and strains. Additionally, long-term exposure tests are conducted to assess the geotextile's durability under simulated environmental conditions, ensuring its performance over time.

- Q: Can geotextiles be used in erosion control in river channel stabilization?

- Yes, geotextiles can be used in erosion control in river channel stabilization. They are commonly used to prevent soil erosion and stabilize river banks by acting as a barrier that allows water to pass through while retaining the soil particles. Geotextiles can effectively control erosion and provide long-term stability to river channels.

Send your message to us

Geotextile Boise Asphalt Reinforcement Fiberglass Geogrid Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords