Geotextil Sodimac Polypropylene Non-Woven Geotextile for River Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Polypropylene Non-woven Geotextile for River Construction:

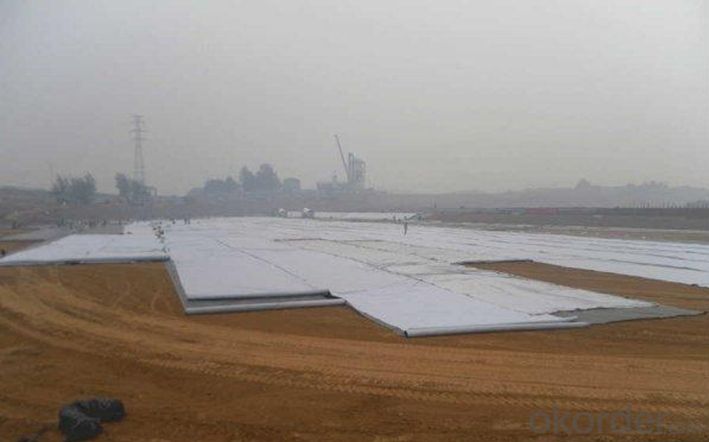

Nonwoven geotextiles are multi-purpose fabrics that are felt-like in appearance. There are numerous practical applications for nonwoven geotextiles. Nonwoven drainage fabrics are an economical alternative to graded aggregate and sand filters and can eliminate many of the problems associated with using, purchasing and transporting aggregate

Features of Polypropylene Non-woven Geotextile for River Construction:

Can withstand the installation stresses

UV stabilized

High chemical resistance

Optimum elongation

Technical Parameters of Polypropylene Non-woven Geotextile for River Construction:

NO. | Item Value | Specification | Note | ||||||||||

| 100 g | 150g | 200g | 250 g | 300 g | 350 g | 400 g | 450 g | 500 g | 600 g | 800 g | ||

1 | Weight Variation% | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width Variation % | -0.5 | |||||||||||

4 | Breaking Strength KN/m ≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD and TD |

5 | Elongation at Break % | 25~100 | |||||||||||

6 | CBR Mullen Burst Strength KN≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

7 | Sieve Size O90 mm | 0.07~0.2 | | ||||||||||

8 | Vertical Permeability | K× (10-1~10-3) | k=1.0-9.9 | ||||||||||

9 | Tear Strength KN≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | MD |

FAQ:

What is the main application of Polypropylene Non-woven Geotextile for River Construction?

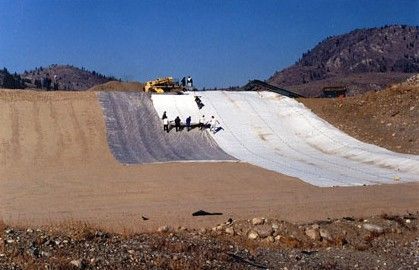

The main application of our Polypropylene Non-woven Geotextile for River Construction is as follows: The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc.

Where is your main market?

Our main market is in Middle East, South America and some African countries.

What is your advantages for PET Continuous Filament Spunbond Needle Punched Nonwoven Geotextile?

One of the largest manufacturer of Polypropylene Non-woven Geotextile for River Construction for Construction with advanced equipment, big production capacity and excellent quality.

- Q: What is the role of geosynthetics in the highway?

- Geosynthetics a lot of geogrid, geotextile which is specific

- Q: How do geotextiles contribute to the stability of landfill slopes?

- Geotextiles contribute to the stability of landfill slopes by providing reinforcement and erosion control. They are placed between different layers of soil to enhance the overall strength and stability of the slope. Geotextiles help to distribute the loads more evenly, preventing excessive settlement and potential slope failure. Additionally, they reduce soil erosion by acting as a barrier against water flow, thus protecting the slope from erosion and maintaining its stability over time.

- Q: What are the key considerations for geotextile installation in corrosive environments?

- The key considerations for geotextile installation in corrosive environments include selecting a geotextile material that is resistant to corrosion, ensuring proper anchoring and fastening methods to prevent movement or damage, conducting regular inspections and maintenance to identify any signs of corrosion, and implementing appropriate protective measures such as using a geotextile with a higher corrosion resistance rating or adding a barrier layer to minimize exposure to corrosive agents.

- Q: How to overcome the problems of impervious geotextile?

- Geotextile is a filter and protection function, itself is permeable. The main material of impermeable material is geomembrane.

- Q: Can geotextiles be used in green roof systems?

- Yes, geotextiles can be used in green roof systems. They can serve multiple purposes such as providing drainage, filtration, and separation layers. Geotextiles help to control water flow, prevent soil erosion, and promote healthy plant growth in green roofs.

- Q: What are the factors to consider when selecting geotextiles for a project?

- When selecting geotextiles for a project, there are several factors to consider. Firstly, it is important to assess the specific requirements of the project. This includes considering the expected load and stress that the geotextiles will need to bear, as well as the expected site conditions such as soil type and water flow. Additionally, the durability and longevity of the geotextiles should be considered, taking into account factors such as UV resistance and resistance to chemical degradation. The cost and availability of the geotextiles should also be taken into account, as well as any specific design or regulatory requirements for the project. Lastly, it is crucial to consider the manufacturer's reputation and the geotextiles' performance history through references and testing data. Overall, a comprehensive evaluation of project requirements, performance characteristics, cost, and availability will help in selecting the most suitable geotextiles for a project.

- Q: What are the factors to consider when maintaining geotextiles?

- When maintaining geotextiles, there are several factors to consider. Firstly, it is important to regularly inspect the geotextiles for any signs of damage or wear. This includes checking for tears, holes, or fraying, as well as monitoring the overall condition of the material. Secondly, it is crucial to properly clean the geotextiles to prevent the buildup of dirt, debris, or organic matter that can compromise their effectiveness. This may involve using appropriate cleaning methods such as gentle washing or vacuuming. Additionally, considering the environmental and weather conditions in the specific location where the geotextiles are installed is essential. Extreme temperatures, UV exposure, and moisture levels can impact the durability and longevity of the material, so appropriate protective measures should be taken to mitigate these factors. Lastly, regular maintenance should include reassessing the performance of the geotextiles and their compatibility with the intended application. This may involve consulting with experts or conducting periodic testing to ensure that the geotextiles continue to meet the required standards and objectives. Overall, diligent inspection, cleaning, protection, and evaluation are key factors to consider when maintaining geotextiles.

- Q: How do geotextiles help with asphalt pavement reinforcement?

- Geotextiles help with asphalt pavement reinforcement by providing additional strength, stability, and durability to the pavement structure. They are placed between the asphalt layers to prevent the mixing of subgrade soil and base material, reducing the potential for pavement distress and rutting. Geotextiles also act as a separation barrier, preventing the intrusion of fines and water into the pavement layers, which can weaken the structure over time. Additionally, they distribute the load more evenly, improving the pavement's ability to withstand traffic loads and reducing the occurrence of cracks and potholes.

- Q: Are geotextiles suitable for use in erosion control mats for revegetation?

- Yes, geotextiles are suitable for use in erosion control mats for revegetation. Geotextiles are designed to prevent soil erosion by stabilizing the soil and promoting vegetation growth. They provide a protective layer that allows water to pass through while retaining soil particles, which helps to reduce erosion. Additionally, geotextiles facilitate the establishment of vegetation by providing a favorable environment for root development. Overall, geotextiles are an effective solution for erosion control in revegetation projects.

- Q: Can geotextiles be used in underground storage tank applications?

- Yes, geotextiles can be used in underground storage tank applications. Geotextiles provide a variety of benefits such as soil stabilization, filtration, and drainage, which are important in underground storage tank installations to mitigate potential issues like soil erosion, water infiltration, and contamination.

Send your message to us

Geotextil Sodimac Polypropylene Non-Woven Geotextile for River Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords