High Modulus Polyethylene Fiberglass Geogrid Geotextile Sizes Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

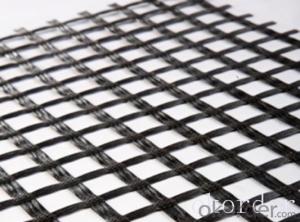

Biaxial

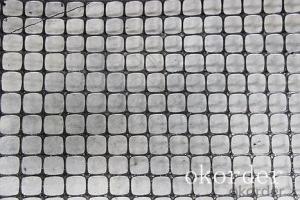

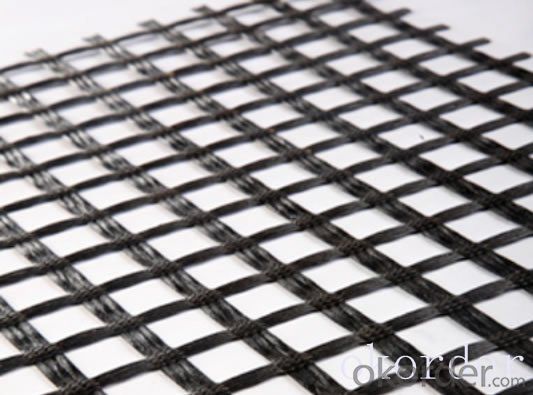

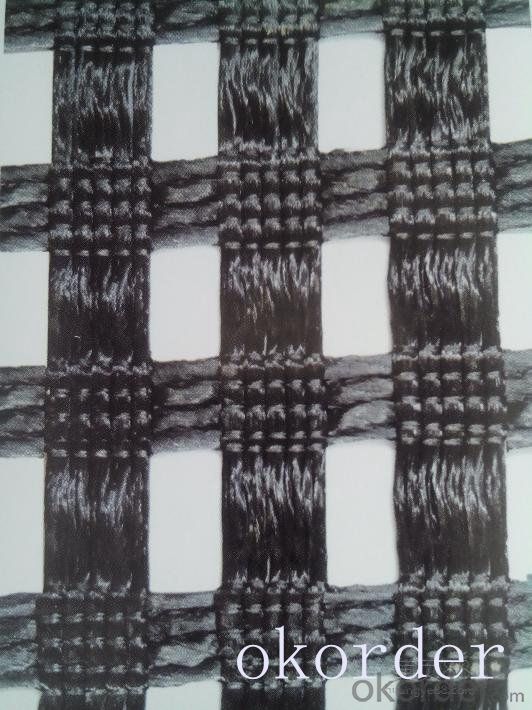

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

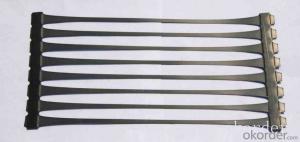

A: Yes, please check the pictures:

- Q: What are the different geotextile filtration testing methods?

- There are several geotextile filtration testing methods used to evaluate the performance of geotextiles. Some of the commonly used methods include the gradient ratio test, the sieve analysis test, the permittivity test, the flow rate test, and the turbidity test. These tests assess the geotextile's ability to filter water, retain soil particles, and prevent clogging.

- Q: Polypropylene geotextile and polyester geotextile with the naked eye how to distinguish

- Polypropylene compared to white, polypropylene fiber than polyester fiber density point, anti-aging anti-aging of polypropylene, polyester aging,

- Q: Can geotextiles be used in the construction of landfills?

- Yes, geotextiles can be used in the construction of landfills. Geotextiles are often used as a barrier or liner material in landfills to help prevent the migration of contaminants and control the flow of leachate. They are commonly used to enhance the stability, durability, and environmental performance of landfill systems.

- Q: How do geotextiles contribute to the stability of railroad ballast?

- Geotextiles contribute to the stability of railroad ballast by providing reinforcement and separation functions. They help prevent the migration of fine particles from the subgrade into the ballast, which can lead to ballast degradation and loss of stability. Additionally, geotextiles distribute loads evenly, reducing differential settlement and increasing the overall stability of the ballast layer.

- Q: How are geotextiles used in landfills?

- Geotextiles are used in landfills as a protective barrier or liner, preventing the contamination of soil and groundwater by acting as a barrier between the waste and the underlying natural environment. They help to control the flow of liquids, filter out pollutants, and provide stability to the landfill structure, ultimately enhancing environmental protection and the longevity of the landfill.

- Q: What are the different manufacturing methods for geotextiles?

- There are several different manufacturing methods for geotextiles, including weaving, knitting, and nonwoven processes. Weaving involves interlacing two sets of yarns, warp, and weft, to create a fabric with an ordered structure. Knitting, on the other hand, uses a series of interconnected loops to form a fabric. Nonwoven processes involve bonding fibers together through methods such as needle punching, thermal bonding, or chemical bonding. Each method has its own advantages and is used depending on the specific requirements of the geotextile application.

- Q: Composite geotextile have what model specifications

- Composite geomembrane; mass per unit area g / m000 Membrane thickness mm0.25-0.350.3-0.5 breaking strength KN / m57.510.012.014.016.018.0 vertical and horizontal elongation at break% 30-100CBR breaking strength KN ≥ 1.11 . 51.92.22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

- Q: Can geotextiles be used in seawall construction?

- Yes, geotextiles can be used in seawall construction. Geotextiles are commonly used as a reinforcing material in seawalls to provide additional strength and stability. They help control erosion, prevent soil movement, and provide filtration to ensure proper drainage in seawall structures.

- Q: Can geotextiles be used in the protection of groundwater sources?

- Yes, geotextiles can be used in the protection of groundwater sources. Geotextiles are permeable fabrics that can be used to create barriers and filters in various applications. When used in groundwater protection, geotextiles can act as a barrier to prevent the movement of contaminants or pollutants from reaching the groundwater sources. They can also be used as filters to separate and remove suspended particles, sediments, or pollutants from stormwater runoff before it infiltrates into the groundwater. Overall, geotextiles can play a crucial role in maintaining the quality and integrity of groundwater sources.

- Q: Mainly how to filter layer construction, cutting for the weak weathering rock

- The walls behind the sandbags ah, but in most cases are mechanical backfill, and then the top surface of a layer of sandbags and composite drainage network mean

Send your message to us

High Modulus Polyethylene Fiberglass Geogrid Geotextile Sizes Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords