Geotextile Membrane for Horse Arena - Pavement Base Reinforcement Geotextile Factory Supply Direct

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nutrition geotextile in water environmental engineering .

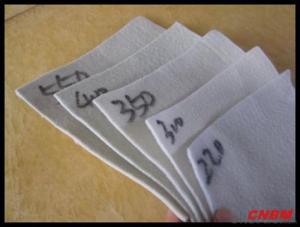

Specification:

Geotextile has excellent permeability, acquired, durability, which can be widely used in railway ,highway, movement hall,Dams,hydraulic structures hence hole, coastal shoal, reclamation,environmental protection and other projects. The main products are Synthetic staple fibers needle punched nonwoven geotextiles and split film yarn woven geotextiles.

Product Feature:

1. Simple and fast construction

2. Achieve the greening effect quickly after construction

3. Due to the grass and composite fiber fabrics become into one integration, so it has the ability of certain degree of flow resistance for the water rising before the grass survive.

4. Composite fiber fabric is a continuous structure from slope top to slope toe, both ends are fixed, has high water flow resistance.

Technical Specification

5.0 m length and 1.05 m width. Reverse side all used filter material. Grass seeds: Bermuda grass (warm season grass), Bahia grass (warm season grass), Kentucky bluegrass (cold season grass), Tall fescue grass (cold season grass), Red fescue grass (cold season grass). Plant height: 0.1 ~ 0.5 m.

| NO. | Items | Specification | Notes | |||

| 1 | Total unit area weight g/sq.m | ≥380 | ||||

| 2 | dimension | width m | 1.0~2.0 | |||

| length m | as per user’s request | |||||

| 3 | Composite fiber fabrics | Material | Polyester Fiber | High strength PET | ||

| Unit area weight g/sq.m | ≥160 | |||||

| Mesh dimension mm | 8×8 | |||||

| Extension strengh kn/m | ≥11 | MD & CD | ||||

| 4 | Filtra layer | Material | Polyester non woven geotextile | |||

| Unit area weight g/sq.m | ≥40 | |||||

| 5 | Grass seeds, Fertilizer | Type | According to actual situation choose 3~5 grass seeds | |||

| Plant height m | 0.1~0.3 | |||||

| 6 | Fiber layer | Material | wood pulp cellulose | |||

| Unit areaweight g/sq.m | ≥15 | |||||

| 7 | flow resistance | ≥4 | not allow appear scour, suction and blanket turn-over etc. damage phenomenon | |||

| M/s | ||||||

| 8 | Anti-UV strengh conservation rate % | 65~80 | 3000hrs Continuously exposure 3000hrs | |||

| 9 | Supporting spare parts | ABS fastening nail | Material | ABS Resin | Fixed between two blankets by length direction | |

| Fiber diameter mm | 35 | |||||

| Nail length mm | 325 | |||||

| Lnail | Material | Steel wire (content 10% zinc-aluminium alloy) | Used to fix single blanket | |||

| Fiber diameter mm | 4 | |||||

| Nail length mm | 200 | |||||

| ABS connecting nail | Material | ABS Resin | Used in the slope between the two blankets ( width direction) | |||

| Nail length mm | 38 | |||||

| Connecting fiber | Material | High strength Polypropylene | Used in the slope between the two blankets ( width direction) | |||

| Length mm | Cut as per request | |||||

APPLICATION:

Generally laid on the river channel, slope protection etc. slope revetment projects, to control the water erosion, soil loss, meantime can reach the effect of slope ecological restoration and landscape greening, making river back to natural.

- Q: Geotextile detection sampling, how many meters

- Two meters by two meters! Geotextile manufacturers to answer!

- Q: Concrete panel shop asphalt do not add geotextiles

- Plus no geotextile cloth according to the design requirements and construction specifications. Generally require high road construction need to lay geotextile. Geotextile manufacturers to answer your questions

- Q: Can geotextiles withstand harsh weather conditions?

- Yes, geotextiles are designed to withstand harsh weather conditions. They are made from durable materials that are resistant to UV rays, moisture, and temperature fluctuations, making them suitable for various environmental conditions. Additionally, geotextiles have high tensile strength and can resist damage caused by heavy rain, wind, and extreme temperatures, ensuring their performance and longevity even in harsh weather conditions.

- Q: Can geotextiles be used in green infrastructure projects?

- Yes, geotextiles can be used in green infrastructure projects. They can serve as a key component in various applications such as erosion control, soil stabilization, and drainage systems. Geotextiles help to improve the overall performance and longevity of green infrastructure by providing reinforcement, filtration, and separation functions.

- Q: Geotextile, 150g how much money per square meter

- 1.2 to 1.5. See quality requirements. Huazhi geotextile material manufacturers

- Q: What glue can clay stickers glue?

- Geotextiles generally do not need to glue glue, because the geotextile is made of polyester staple fiber acupuncture, the product itself has a lot of small pores, the use of glue bonding not only a waste of glue, bonding effect is not good. Geotextile in the project is generally used in the hand-type sewing machine suture, suture geotextile not only glue glue than the geotextile solid and reliable, and the construction of geotextile suture is also much higher than the construction of glue with geotextile Speed, while the cost of sewing geotextile is also much lower than the cost of glue bonding geotextile. Generally in the project to play the effect of impervious geomembrane, composite geomembrane (also known as composite geotextile) can use glue bonding. Adhesive glue can be purchased in the geomembrane manufacturer, of course, you can also buy in the local building materials market, waterproof plastic or KS geomembrane special glue. These two glue can also be used to bond geotextiles.

- Q: Can geotextiles be used in shoreline erosion control projects?

- Yes, geotextiles can be effectively used in shoreline erosion control projects. Geotextiles are permeable fabrics that can be installed along shorelines to stabilize the soil and prevent erosion caused by waves and currents. They can be used as a layer to separate the soil from the water, allowing for water filtration while reducing soil erosion.

- Q: Are geotextiles suitable for use in landfill applications?

- Yes, geotextiles are suitable for use in landfill applications. They are commonly used to separate the waste from the underlying soil, providing stability and preventing the mixing of different materials. Geotextiles also help with drainage and filtration, reducing the risk of groundwater contamination. Additionally, they can enhance the overall performance and lifespan of the landfill by reducing erosion and increasing the structural integrity of the waste containment system.

- Q: U400 geotextile u400 what it means

- Is not 400g / ㎡ of geotextile? My company specializes in the production of geotextiles, details (hand) to see capital (machine) material

- Q: Composite geotextile plastic composite

- 1, plastic composite geotextile is woven with a woven fabric as the substrate, the extruded coated polyolefin resin film or polyolefin resin sandwich layer, the woven cloth and all kinds of Zhang made together. 2, the product made of bags with light weight, acid and alkali resistance, strength, moisture and other advantages. 3, widely used in chemical fertilizer, synthetic resin, coarse salt, ore and cement products such as packaging, is a good packaging of heavy packaging materials

Send your message to us

Geotextile Membrane for Horse Arena - Pavement Base Reinforcement Geotextile Factory Supply Direct

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords