Polyester Mat Used For SBS/APP Waterproof Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

Polyester Mat Used For SBS/APP Waterproof Membrane take the “Skin” type waterproof thought, according to the features of construction site, on the basis of width elastomeric modified bitumen waterproofing membrane, combining with features of wet-application self-adhesive membrane, use advanced equipment to produce 2 meters width that WP-SBS wet-application width elastomeric modified bitumen waterproofing membrane (Hereinafter referred to: WP-SBS membrane).WP-SBS is made of bitumen modified with Styrene-Butadiene- Styrene (SBS)as dipping and painting. Its upper surface covers PE membrane and color sand or schist, and lower surface is made of isolation material. Products correspond to the national standards GB18242-2008(elastomeric modified bitumen waterproofing membrane), paste by cement or cement mortar, and construct on the wet base, achieving tight and full adhesion with substrates, eliminating fluid-channeling layer, all above contribute to making a reliable “Skin” type waterproof system, which is a breakthrough innovation in ordinary modified bitumen membrane.

Packaging & Shipping

1. Different types and specifications of the product should be piled up respectively, not be mixed.

2. Avoid sun and rain, pay attention to ventilation. Storage temperature should not be higher than 50°C.

3. Membranes should be flat during transport and storage, flat stacking height not more than four levels. Prevent tilt or pressure during transportation, sealed by the felt cloth if necessary

4. Under the normal storage and transport conditions, storage period is one year from the date of production.

.

Advantagee

1. 2m width, Reduce Overlap

2. Simple and Efficient Construct, Greatly Saving Construct Period

3. Adhesive Reliable, Avoid Fluid-channeling

4. Advanced Production Line

5. Excellent Comprehensive Physical Properties

6. Stable Dimension

7. Wide Adaptability of Facing Material

Application method

1.Make sure the roof deck smooth ,clean and dry(Moisture<9%),then apply the surface of roof deck homogeneously with a kind bitumen paint till dry to start application.

2.There are two methods in application:

One way is by heating and melting method---Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted (not flowing),then install the membrane fully bonded to the roof deck with overlaps of 5-10cm.

The other way is by cold adhesive method---Pour the cold adhesive homogeneously on the roof deck then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation in application as requested.

3.After application ,a full serious inspection is required to make sure no air bubble ,no fold,no falling away etc to guarantee the waterproof life.

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Storage:

Different types or specifications of products should be separated, not mixed.

Keep it dry and ventilated, protected from the sun or rain.

Storage temperature should never be higher than 45 °C. Pile up the membranes flatwise whose stockpile height never exceeds five layers. One layer is guaranteed if it is placed vertically.

Prevent it from inclination or In the process of transportation, it should be lying in case of inclination or lateral pressure. If necessary, cover it with felt-cloth.

Storage time is at least one year from manufacture date on if the product is under normal operation of storage.

Technical Parameters

Item | Index | ||||||

1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

Max elongation% ≥ | - | - | 15 | - | - | ||

Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

4 | Cold bonding | -25°c No cracks | |||||

5 | Watertightness | 0.3mPa,2h waterproof | |||||

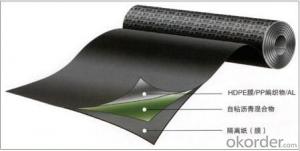

product show

FAQ

Q: What's the de6abf1fe186f8d58506cbcfe46eed814d.jpglivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oils?

- Yes, a waterproofing membrane is generally resistant to hydrocarbons or oils. The materials used in waterproofing membranes, such as bitumen or synthetic polymers, are typically designed to have high resistance to various chemicals, including hydrocarbons and oils. This resistance helps to ensure that the membrane remains effective in preventing water penetration even in the presence of these substances. However, it is important to note that the specific resistance level may vary depending on the type and quality of the waterproofing membrane. It is always recommended to consult the manufacturer or supplier to determine the exact resistance capabilities of a specific waterproofing membrane.

- Q: Can a waterproofing membrane be used in conjunction with vapor barriers?

- Yes, a waterproofing membrane can be used in conjunction with vapor barriers. While a waterproofing membrane protects against liquid water infiltration, a vapor barrier is designed to prevent the passage of moisture vapor. By combining both, you can effectively protect a structure from both liquid water and moisture vapor, ensuring a comprehensive moisture management system.

- Q: Can a waterproofing membrane be used in historical or heritage buildings?

- Yes, a waterproofing membrane can be used in historical or heritage buildings. However, it should be done with caution and expertise to ensure that the membrane does not compromise the historical integrity or aesthetic value of the building. The selection and installation of the membrane should be carried out by professionals who understand the specific requirements and challenges associated with preserving the architectural significance of such buildings.

- Q: Sbs modified asphalt waterproof membrane polyester type Ⅰ type Ⅱ how to distinguish

- SBS modified asphalt waterproofing membrane is SBS rubber modified petroleum asphalt cited as the invasion coating, polyester fiber non-woven fabrics, jute cloth, fiberglass mats were made for the fetal base, the plastic film for the anti-sticking isolation Layer, by the selection, ingredients, eutectic, invasion, composite molding, curling and other processes processing production.

- Q: Can a waterproofing membrane be used for a warehouse?

- Yes, a waterproofing membrane can be used for a warehouse. A waterproofing membrane is a product that is designed to prevent water penetration and protect structures from moisture damage. It can be applied to various surfaces, including concrete, metal, and wood, making it suitable for warehouses made of different materials. Using a waterproofing membrane in a warehouse can provide several benefits. Firstly, it helps to prevent water intrusion, which is particularly important in areas with high rainfall or near bodies of water. By preventing water from seeping into the warehouse, it can help protect the contents of the warehouse from water damage, such as rust, mold, and decay. Additionally, a waterproofing membrane can help to improve the overall structural integrity of the warehouse. Moisture can weaken the materials used in the construction of the warehouse, leading to potential structural issues over time. By creating a barrier against water, a waterproofing membrane can help extend the lifespan of the warehouse and reduce the need for costly repairs. Moreover, a waterproofing membrane can also contribute to a healthier indoor environment in the warehouse. By preventing water intrusion, it reduces the risk of mold growth, which can be detrimental to the air quality and the health of the occupants. This is particularly important if the warehouse stores sensitive goods or if workers spend significant amounts of time in the facility. In conclusion, a waterproofing membrane can indeed be used for a warehouse. It offers protection against water intrusion, improves structural integrity, and contributes to a healthier indoor environment. Selecting the appropriate waterproofing membrane and ensuring proper installation is crucial to ensure optimal performance and long-lasting protection for the warehouse.

- Q: Can a waterproofing membrane be installed by a homeowner, or is professional installation necessary?

- Depending on the complexity and scale of the project, a homeowner may choose to install a waterproofing membrane themselves or hire professionals. Waterproofing membranes serve to prevent water penetration in basements, roofs, or shower enclosures. For uncomplicated tasks like sealing a small basement crack, homeowners with some DIY experience can typically handle the installation of a waterproofing membrane. The market offers a variety of do-it-yourself products that come with user-friendly instructions. These products often include self-adhesive membranes or liquid waterproofing coatings that can be applied using a brush or roller. However, for larger or more intricate waterproofing projects, it is advisable to seek professional assistance. Professional waterproofing companies possess the necessary expertise, specialized tools, and experience to ensure a proper and long-lasting installation. They can assess the specific requirements of the project, identify potential problem areas, and recommend the most suitable waterproofing membrane system. Additionally, professional installation typically includes warranties that provide peace of mind and protection against future issues. To summarize, while homeowners can handle small and straightforward waterproofing projects, it is recommended to consult professionals for larger or more complex installations to achieve optimal results and long-term durability.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces of a structure?

- Yes, a waterproofing membrane can be used on both interior and exterior surfaces of a structure. Waterproofing membranes are designed to create a barrier that prevents water or moisture from penetrating into the structure, whether it is applied on the inside or outside. On the interior, a waterproofing membrane can be used to protect basements, crawl spaces, or other areas prone to moisture intrusion. This helps to prevent water damage, mold growth, and other issues that can arise from excess moisture in these spaces. On the exterior, a waterproofing membrane is commonly used to protect the foundation, walls, and other structural elements from water infiltration. This is especially important in areas with heavy rainfall or where the water table is high. By applying a waterproofing membrane on the exterior, it helps to keep the structure dry and prevents potential damage caused by water seepage. It is important to note that different types of waterproofing membranes are available for specific applications, so the selection of the appropriate membrane will depend on the specific requirements of the project.

- Q: Can a waterproofing membrane be used for a retaining wall drainage?

- Using a waterproofing membrane is an effective method for retaining wall drainage. Typically used to prevent water from penetrating structures like basements or foundations, this membrane can also serve as a barrier against water seepage in retaining wall construction. Retaining walls are designed to hold back soil and prevent erosion, but without proper construction, they can be vulnerable to water damage. If water seeps through, it can create pressure behind the wall, causing structural problems over time. By installing a waterproofing membrane on the backside of the retaining wall, water infiltration into the soil and accumulation behind the wall can be prevented. Furthermore, a waterproofing membrane can help with the drainage of water away from the retaining wall. By incorporating drainage systems like weep holes or French drains, alongside the membrane, water can be directed away from the wall, reducing hydrostatic pressure and potential damage. It's important to note that while a waterproofing membrane can be used for retaining wall drainage, proper installation and compatibility with the specific retaining wall system and conditions are crucial. It's recommended to consult with a professional engineer or contractor experienced in retaining wall construction to ensure the most suitable approach for your specific project.

- Q: Can a waterproofing membrane be used on both interior and exterior walls?

- Yes, a waterproofing membrane can be used on both interior and exterior walls. The membrane helps prevent water penetration, providing protection against moisture for both sides of the wall.

- Q: Can a waterproofing membrane be used for a fountain waterproofing system?

- Yes, a waterproofing membrane can be used for a fountain waterproofing system. Waterproofing membranes are designed to provide a barrier against water penetration and are commonly used in various applications, including fountains. They can effectively protect the structure and prevent water leakage, ensuring the durability and functionality of the fountain.

Send your message to us

Polyester Mat Used For SBS/APP Waterproof Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords