APP/SBS Waterproof Membranes In Polyester Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

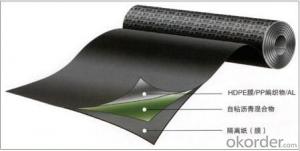

sbs waterproof membrane take the “Skin” type waterproof thought, according to the features of construction site, on the basis of width elastomeric modified bitumen waterproofing membrane, combining with features of wet-application self-adhesive membrane, use advanced equipment to produce 2 meters width that WP-SBS wet-application width elastomeric modified bitumen waterproofing membrane (Hereinafter referred to: WP-SBS membrane).WP-SBS is made of bitumen modified with Styrene-Butadiene- Styrene (SBS)as dipping and painting. Its upper surface covers PE membrane and color sand or schist, and lower surface is made of isolation material. Products correspond to the national standards GB18242-2008(elastomeric modified bitumen waterproofing membrane), paste by cement or cement mortar, and construct on the wet base, achieving tight and full adhesion with substrates, eliminating fluid-channeling layer, all above contribute to making a reliable “Skin” type waterproof system, which is a breakthrough innovation in ordinary modified bitumen membrane.

Characteristic

1.Good impermeability

2.Possess good tensile strength, elongation and size stability which could be well suited the substrate distortion and crack.

3.Good performance in anti-strength, anti-resistance , anti-erosion, anti-mildew, anti-weathering

4.SBS modified bitumen membrane is specially being applied in the cold area with low temperature, while APP modified bitumen membrane is applied in the area with high temperature.

5.Convenient installation

Applicable scope:

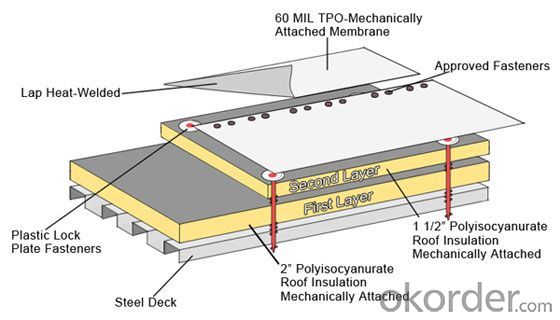

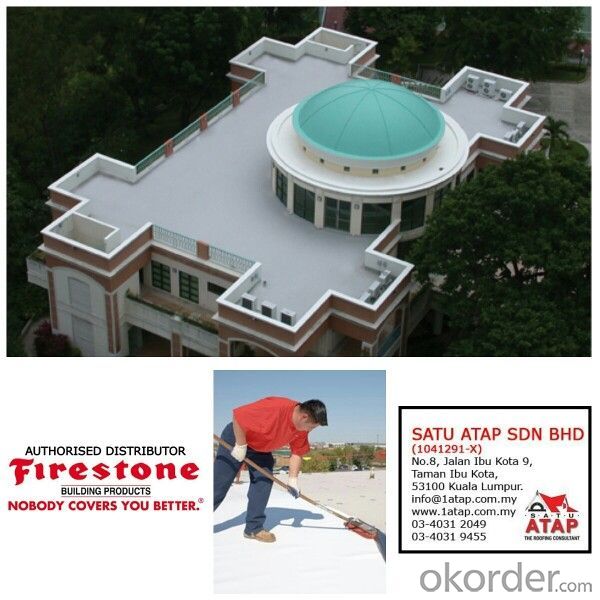

It is widely used for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproofing, especially for the building under high temperature.

Application

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Packaging & Shipping

| Packing | Woven bag/PE bag packing or as customer request |

| Shipping | FOB Changsha,customized shipping terms and oppointed port accepted |

Technical parameter

| Item | Specifications | ||||||||

| Geotextile Unit Weight (g/m²) | 300 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | |

| Geomembrane Thickness (mm) | 0.25-0.35 | 0.30-0.50 | |||||||

| Nominal Fracture Strength (KN/m) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Breaking Strength (KN/m,≥,LD/TD) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Standard Intensity Corresponding Elongation Rate (%) | 30~100 | ||||||||

| CBR Burst Strength (KN,≥) | 0.70 | 1.50 | 1.90 | 2.20 | 2.50 | 2.80 | 3.00 | 3.20 | |

| Longitudinal Tear Strength (KN,≥) | 0.05 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic Pressve (Mpa) | See List Below | ||||||||

| Peel Strength (N/cm,≥) | 6 | ||||||||

| Vertical Permeability Coefficient (cm/s) | According to design or contract mentioned. | ||||||||

| Width Variation (%) | -1.00 | ||||||||

| Item | Geomembrane Thickness (mm) | ||||||||

| 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 1.00 | ||

| Hydrostatic Pressve (Mpa) | One geotextiles with one geomembrane | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| Two geotextiles with one geomembrane | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | |

Professional test machines ensure the products qualified roduct certifications

roduct certifications

Inquiry Note

How to send an effective inquiry for saving your time?

product show

FAQ

- Q: Can a waterproofing membrane be used for a balcony deck coating?

- Yes, a waterproofing membrane can be used for a balcony deck coating. Waterproofing membranes are often used to protect and seal balconies and decks from water damage, providing a durable and long-lasting solution.

- Q: It is good for black roof with waterproof paper

- SBS surface is divided into: PE film, no film, Liao film, sand surface, shale surface and other categories. The blacks mentioned in the problem belong to PE film and no film, and the silver is the membrane of the membrane. There is no difference between the use of good or bad comparability.

- Q: Are waterproofing membranes resistant to water vapor transmission?

- Waterproofing membranes possess a resistance to the transmission of water vapor. These membranes function to construct a barrier, effectively hindering water penetration. Typically composed of impermeable materials like rubber, plastic, or bitumen, they effectively obstruct the flow of liquid water, preventing its infiltration into the underlying structure. Nevertheless, it is worth noting that although waterproofing membranes can effectively resist the transmission of water vapor, it may not entirely eradicate it. A certain degree of water vapor may still manage to permeate the membrane, albeit significantly reduced in comparison to materials not specifically intended for waterproofing.

- Q: Can a waterproofing membrane be used for water treatment plants?

- Indeed, water treatment plants can benefit from the utilization of waterproofing membranes. These specialized membranes are specifically engineered to impede the flow of water, making them an ideal solution for safeguarding against water seepage in diverse structures, including water treatment plants. By applying these membranes to various sections of the facility, such as tanks, reservoirs, pipes, and basements, infiltration of water can be effectively prevented, thus shielding the infrastructure from potential harm. Furthermore, the implementation of waterproofing membranes aids in preserving the integrity of the water treatment process by ensuring that water remains confined within designated areas and does not permeate the surrounding soil or structures.

- Q: Can a waterproofing membrane be installed on any surface?

- When installing a waterproofing membrane, there are several factors to take into account. The condition and composition of the surface, as well as the type of membrane being used, determine its suitability. Typically, waterproofing membranes are designed to adhere to various substrates like concrete, wood, metal, and masonry. They can be applied to surfaces such as roofs, foundations, basements, bathrooms, and balconies. However, it is crucial to ensure that the surface is clean, dry, and free from contaminants like dirt, debris, or loose materials before installing the membrane. In addition, certain surfaces may require additional preparatory work or primers to enhance adhesion and ensure a long-lasting waterproofing solution. For example, rough or uneven surfaces may need to be leveled or smoothed before applying the membrane. The specific requirements of the waterproofing system being used should also be considered. Different membranes have different application methods and compatibility with surfaces. Some membranes may be more suitable for horizontal surfaces like flat roofs, while others may be better suited for vertical surfaces like walls or foundations. Ultimately, it is recommended to consult a professional waterproofing contractor or refer to the manufacturer's guidelines to determine the compatibility of the membrane with a specific surface and ensure proper installation for optimal performance and longevity.

- Q: Can a waterproofing membrane be used on concrete block walls?

- Concrete block walls are prone to water infiltration, which can cause problems like mold, mildew, and structural harm. To combat this, a waterproofing membrane can be utilized on the walls. This membrane acts as a protective shield, applied to the surface of the concrete blocks, effectively stopping water from seeping in. By creating a moisture-resistant barrier, it establishes a tight seal, preventing water from entering the interior of the walls. This aids in preserving the walls' integrity and safeguards against water-related damage. However, it is crucial to ensure that the waterproofing membrane is correctly installed and that any existing cracks or gaps in the concrete block walls are adequately sealed before its application.

- Q: How does a waterproofing membrane handle construction joints?

- A waterproofing membrane is designed to provide a protective barrier against water penetration in construction applications. When it comes to construction joints, which are commonly found in concrete structures, the membrane is specifically engineered to handle these areas. During the construction process, joints are created to allow for movement between different sections of the structure. These joints can be vulnerable points where water can potentially infiltrate. To address this concern, waterproofing membranes are installed to ensure that these joints remain watertight. There are different methods used to handle construction joints with waterproofing membranes. One common approach is to apply the membrane directly over the joint, extending it beyond the joint edges. This creates a continuous waterproof layer that covers both the joint and the adjoining areas. Another technique involves the use of specially designed joint tapes or strips that are embedded within the membrane. These tapes or strips are typically made of materials like rubber or PVC and are placed directly over the joint before the membrane is applied. They serve as an additional layer of protection, enhancing the waterproofing performance of the membrane at the joint. In addition to these methods, there are also specialized waterproofing systems available that include pre-formed joint sealants. These sealants are designed to fit snugly into the joint, providing a tight seal against water intrusion. The membrane is then installed over the joint, ensuring comprehensive waterproofing coverage. Overall, a waterproofing membrane is specifically designed to handle construction joints by providing a durable and effective barrier against water penetration. Whether through extending the membrane over the joint, using joint tapes or strips, or incorporating pre-formed joint sealants, these membranes ensure that construction joints remain watertight, protecting the structure from potential water damage.

- Q: Are waterproofing membranes resistant to freeze-thaw cycles?

- Waterproofing membranes, in general, exhibit resistance towards freeze-thaw cycles. Their design caters to enduring severe weather patterns, which encompass freezing temperatures and subsequent thawing. The selection of materials for these membranes is often based on their durability and capacity to expand and contract without jeopardizing their waterproofing capabilities. This resilience against freeze-thaw cycles guarantees the preservation of membrane integrity and efficacy in obstructing water infiltration, irrespective of regions experiencing frequent temperature fluctuations.

- Q: Are there any specific safety precautions to consider when installing a waterproofing membrane?

- Yes, there are several safety precautions to consider when installing a waterproofing membrane. Firstly, it is important to wear proper personal protective equipment (PPE) such as gloves, goggles, and a respirator to protect against potential chemical exposure and inhalation of fumes. Additionally, ensure adequate ventilation in the work area to prevent the buildup of fumes. It is also crucial to follow the manufacturer's instructions and guidelines for installation to minimize the risk of accidents or improper application. Lastly, be cautious of potential hazards such as slippery surfaces, sharp edges, or working at heights, and take necessary precautions to prevent falls or injuries.

- Q: Can a waterproofing membrane be used for plant rooms or mechanical spaces?

- Yes, a waterproofing membrane can be used for plant rooms or mechanical spaces. These areas often require protection against water damage due to the presence of pipes, equipment, or other mechanical systems. A waterproofing membrane provides an effective barrier to prevent water intrusion and protect the integrity of the space.

Send your message to us

APP/SBS Waterproof Membranes In Polyester Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords