8xxx Series Mill Finished Stucco Embossed Aluminum Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Mill Finined Aluminum Sheets 8xxx Description

Mill Finined Aluminum Sheets 8xxx is cut from aluminum coils 8xxx.. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Mill Finined Aluminum Sheets 8xxx is clean, flat, no wrinkle, no scratch, oil free, widly used in construction /Furniture/decorate/industry,etc.

2.Main Features of Mill Finined Aluminum Sheets 8xxx

• excellent quality,good credit

• competitive price,comfortable service

• Goode mechanical property

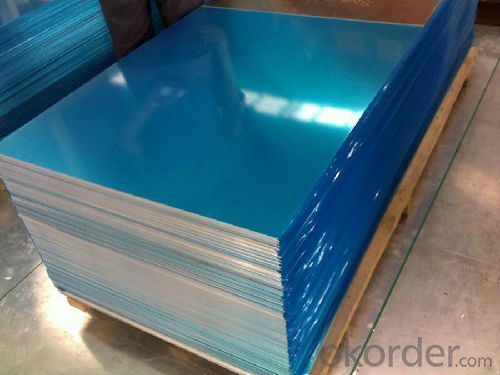

3.Mill Finined Aluminum Sheets 8xxx Images

4.Mill Finined Aluminum Sheets 8xxx Specification

Alloy | AA8xxx (AA8011 etc.) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,ASTM |

5. FAQ of Mill Finined Aluminum Sheets 8xxx

A.What is the MOQ?

The MOQ for each size is 8 tons, because it is D.C quality.

B. Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: Is it possible to utilize aluminum sheets for creating signs or banners?

- <p>Yes, you can use aluminum sheets to make signs or banners. Aluminum is a popular choice due to its durability, lightweight, and resistance to weather conditions. It can be easily cut, shaped, and printed on, making it ideal for outdoor signage. Additionally, aluminum sheets can be coated or laminated to enhance their visual appeal and protect against scratches and fading.</p>

- Q: Can 101 aluminum sheets be bent without cracking or breaking?

- No, it is highly unlikely that 101 aluminum sheets can be bent without cracking or breaking.

- Q: What are the different forming techniques for aluminum sheets?

- Aluminum sheets can be shaped using several different forming techniques. One technique commonly used is bending, where force is applied to the sheet to achieve the desired shape. This can be done manually with a press brake or through automated processes like roll forming or stretch forming. Another technique, called deep drawing, involves using a die and punch to stretch the aluminum sheet into a three-dimensional shape. This method is often employed to create cylindrical or box-shaped components such as cans or containers. Hydroforming is another option for shaping aluminum sheets. It utilizes hydraulic pressure to mold the sheet against a form or mold. This technique is particularly useful for creating complex and irregular shapes that would be challenging to achieve with other methods. For creating symmetrical shapes like bowls or cones, spinning is a commonly used technique. It entails rotating the aluminum sheet against a mandrel while applying pressure to shape it into the desired form. Lastly, there is a technique known as stamping, which involves pressing the aluminum sheet against a die to create a specific shape. This technique is frequently employed in high-volume production of components such as automotive body panels. In conclusion, these forming techniques provide a wide range of options for shaping aluminum sheets into various forms and designs. This allows for flexibility and versatility in manufacturing processes.

- Q: The only materials i can use is iodine, water, HCl, magnet, and pH paper. How do you identify aluminum with that?

- To start with, are you refering to aluminum as metal, an aluminum compound, or a solution with aluminum present as ions? If it is metaallic aluminum, it won't stick to a magnet, and it will react with HCl, however this isn't sufficient to definately say it is aluminum, it would be better to get a density, melting point, etc.

- Q: Are aluminum sheets suitable for harsh weather conditions?

- Aluminum sheets are highly suitable for harsh weather conditions due to their exceptional properties. Aluminum is a lightweight yet durable material that offers excellent resistance against corrosion, rust, and UV radiation. This makes it particularly resilient against the damaging effects of extreme weather conditions such as heavy rain, snow, high winds, and intense sunlight. Furthermore, aluminum has a high strength-to-weight ratio, allowing it to withstand the pressure exerted by severe weather without sustaining significant damage. Additionally, aluminum sheets can be coated with protective finishes such as anodization or powder coating, further enhancing their ability to withstand harsh climates. Overall, aluminum sheets are an excellent choice for applications requiring resilience in harsh weather conditions.

- Q: Can the aluminum sheets be used for manufacturing musical instruments?

- Yes, aluminum sheets can be used for manufacturing musical instruments. Aluminum is a lightweight and versatile material that offers several advantages for instrument manufacturing. It is known for its excellent sound transmission properties, which makes it suitable for creating resonant and vibrant tones in musical instruments. Additionally, aluminum is highly durable and resistant to corrosion, ensuring that the instruments will withstand the test of time. Many percussion instruments, such as cymbals and bells, are commonly made from aluminum sheets due to their ability to produce clear and rich sounds. Moreover, aluminum can also be shaped and formed into various instrument components, making it a popular choice for constructing brass instruments like trumpets and trombones. Overall, aluminum sheets are a viable option for manufacturing musical instruments and have been successfully utilized in the industry.

- Q: What are the different methods of surface protection for aluminum sheets?

- There are several different methods of surface protection for aluminum sheets. One common method is anodizing, which involves creating a protective oxide layer on the surface of the aluminum. This process involves immersing the sheets in an electrolyte solution and passing an electric current through them. The result is a thick, durable, and corrosion-resistant layer that can be further enhanced with various dyes and sealants. Another method is powder coating, where a dry powder is applied to the aluminum sheets and then cured under heat. This creates a hard and resistant coating that provides excellent protection against scratches, chemicals, and weathering. Powder coating is available in a wide range of colors and finishes, making it a popular choice for decorative purposes. Chemical conversion coating is another option, which involves treating the aluminum sheets with a chemical solution to convert the surface into a protective layer. This coating improves corrosion resistance and also provides a good base for paint or other coatings. Painting is also commonly used to protect aluminum sheets. Various types of paints can be applied to the surface, including epoxy, acrylic, and polyurethane-based coatings. These paints not only provide protection against corrosion and environmental factors but also offer aesthetic customization options. Lastly, laminating is a method where a protective film is applied to the surface of the aluminum sheets. These films can be made from various materials such as PVC, polyester, or polyethylene. Laminating provides an additional layer of protection against scratches, abrasion, and UV radiation. Each method of surface protection for aluminum sheets has its own advantages and considerations, depending on the specific requirements of the application. It is important to carefully assess the desired level of protection, aesthetic preferences, and budget constraints before selecting the most suitable method.

- Q: How do aluminum plates open holes?

- The opening of the aluminum plate is a relatively simple process,You can do that with a micro electric device like an electric drill or a grooving machine

- Q: Are the aluminum sheets suitable for manufacturing consumer goods?

- Yes, aluminum sheets are suitable for manufacturing consumer goods. Aluminum is a lightweight, durable, and corrosion-resistant material that can be easily formed, molded, or cut into various shapes. Its versatility makes it ideal for producing a wide range of consumer goods such as kitchen utensils, packaging materials, electronics, furniture, and automotive parts. Additionally, aluminum is recyclable, making it an environmentally friendly choice for sustainable manufacturing.

- Q: How do you clean aluminum sheets?

- Achieving cleanliness for aluminum sheets involves a few straightforward steps: 1. Initiate the process by eliminating any loose dirt or debris from the aluminum sheet's surface. Use a soft brush or cloth to gently sweep away any particles. 2. Create a cleaning solution by combining warm water with a mild detergent or dish soap. It is crucial to avoid strong chemicals or abrasive cleaners since they can harm the aluminum. 3. Submerge a soft cloth or sponge into the cleaning solution and delicately scrub the aluminum sheet. Ensure that the entire surface is covered, giving extra attention to any stains or spots. 4. In the case of persistent stains or marks, utilize a non-abrasive cleaner specifically designed for aluminum. Apply the cleaner onto a soft cloth and gently rub it onto the affected area until the stain is eliminated. 5. Thoroughly rinse the aluminum sheet with clean water to eliminate any soap residue. This step is vital to prevent the accumulation of residue or streaks on the surface. 6. Dry the aluminum sheet completely using a soft towel or cloth. Verify that there is no remaining moisture as it can lead to water spots or corrosion over time. 7. To enhance shine and provide protection, apply a thin layer of aluminum polish or wax. This procedure aids in restoring the luster and safeguarding the aluminum from future tarnish or oxidation. It is important to acknowledge that the cleaning technique may differ based on the type of dirt or oxidation present on the aluminum sheet. Always refer to and adhere to the manufacturer's instructions for specific cleaning recommendations.

Send your message to us

8xxx Series Mill Finished Stucco Embossed Aluminum Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords