Embossed Aluminum Sheets Houston - Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminumtrade plate have great suctility, heat conductivity, anti-corrosion andmoisture resistance properties.

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754,5083,8011, etc

Temper: H14/16/18/22/24/32, HO etc.

Thickness: 0.2mm—100mm

Width: 100mm—2300mm (Can be slitted)

Application:

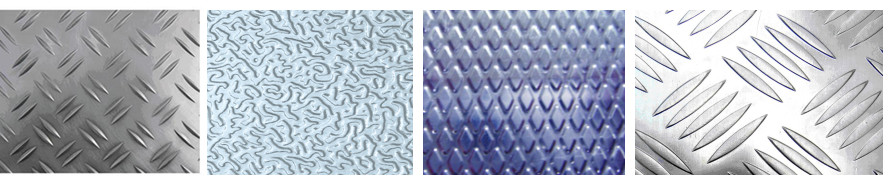

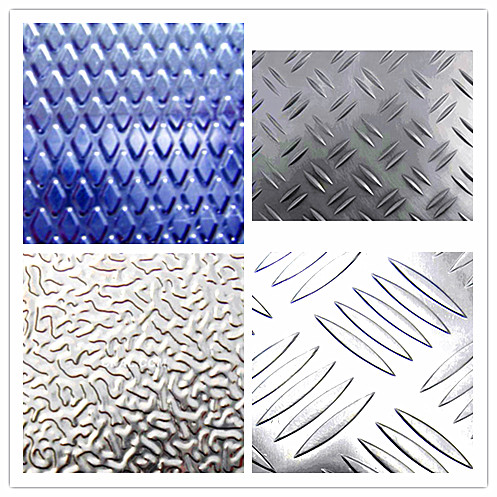

Anti-slipery purpose in vehicles,packing and appliance, decorative purpose

Business Items

1. Payment: T/T or LC at sight

2. Delivery time: 20 Days

3. Packing:

(1) EPE:protect aluminum.

(2) Plastic sheet:water-proof

(3 )Carton:anti-shock.4 Steel bar:fix

4. Quality: Mill Finish, Totally free from defects like White Rust, Roll Marks, Edge damage , Camber,Dents,Holes,Break Lines, Scratch

Dimensions can be produced according to your specifications,if you need any further details,please be free to tell us,we assure you of our best servieces.

If you are interested in our products, please contact us.

- Q: Aluminum and oxygen gas react to produce aluminum oxide

- Aluminium oxide is Al2O3, so there are 3 oxygen atoms for every 2 aluminium atoms. Divide 75 by the relative atomic mass of oxygen (15.9994). That is proportional to the number of oxygen atoms. Then divide by 3 and multiply by 2. This gives a number proportional to the number of aluminium atoms. Then multiply this by the relative atomic mass of aluminium (26.981529) to give the mass of aluminium required in grams.

- Q: What are aluminum sheets used for?

- Due to their unique properties and versatility, aluminum sheets find a wide range of uses. In the construction industry, they are commonly employed for roofing, siding, and cladding, thanks to their lightweight nature, corrosion resistance, and durability. These qualities make them ideal for such purposes. In the transportation industry, aluminum sheets are widely utilized in the manufacturing of automobiles, trains, and aircraft due to their high strength-to-weight ratio. They also serve as a lightweight yet sturdy solution for trailers, truck bodies, and shipping containers. Another significant application of aluminum sheets lies in the manufacturing of consumer products. They are used to make household appliances, cookware, and electronics, as they possess excellent thermal conductivity and resistance to rust and corrosion. Additionally, their ability to withstand various weather conditions makes them suitable for the production of signage, billboards, and displays. In the packaging industry, aluminum sheets play a crucial role in the production of cans, foils, and lids. Their impermeability to light, moisture, and oxygen helps preserve the freshness and quality of food and beverages. Moreover, aluminum sheets have various industrial applications. They are utilized in the fabrication of industrial machinery, equipment, and tools due to their excellent machinability and strength. Additionally, their thermal and electrical conductivity makes them suitable for the production of heat exchangers, solar panels, and electrical conductors. In summary, aluminum sheets find application in construction, transportation, consumer products, packaging, and various industrial sectors, owing to their lightweight, corrosion resistance, durability, thermal conductivity, and electrical conductivity.

- Q: Can 101 aluminum sheets be anodized?

- Indeed, the anodization of 101 aluminum sheets is feasible. Anodization, which entails the formation of a safeguarding oxide layer on the aluminum's surface, enhances its resilience against corrosion and overall durability. This technique can be employed on different aluminum grades, including 101, to achieve desired finishes and offer added protection. The anodization process can be executed through diverse methods such as chromic acid anodizing, sulfuric acid anodizing, or hardcoat anodizing, depending on specific needs and desired outcomes. Consequently, it is assured that 101 aluminum sheets can undergo anodization procedures.

- Q: Cooks are warned not to use aluminum cookware when preparing acidic foods. Why?

- The reacton will make the food taste bad..metalic. Aluminun will poisen your body. We should never use alluminum cookware.

- Q: What are the different methods of cutting aluminum sheets?

- There are several methods of cutting aluminum sheets, including shearing, sawing, laser cutting, waterjet cutting, and CNC milling. Each method has its advantages and suitability depending on the thickness and complexity of the aluminum sheet, as well as the desired precision and speed of the cut.

- Q: 5052 can aluminum plate be machined with laser cutting machine?

- Can cut, but the incision does have cut marks, if processing 3 mm below the thickness, incision quality will be better.

- Q: I saw a nice looking set of cast aluminum pots for a very good price. They feel very heavy. But I remember hearing that aluminum is not healthy so I am wary of buying them. Any advice would be appreciated.

- The cast aluminium pot are used in families, hotels and for any needs. They are very safe to cook.

- Q: Are the aluminum sheets suitable for manufacturing consumer goods?

- Yes, aluminum sheets are suitable for manufacturing consumer goods. Aluminum is a lightweight, strong, and malleable material that can be easily formed into various shapes and sizes. It has excellent corrosion resistance, which makes it ideal for products that may be exposed to moisture or other harsh conditions. Additionally, aluminum is highly recyclable, making it an environmentally friendly choice. Its aesthetic appeal, durability, and versatility make aluminum sheets an excellent option for manufacturing consumer goods such as kitchen utensils, appliances, furniture, packaging materials, and automotive parts.

- Q: Can aluminum sheets be used for protective barriers?

- Yes, aluminum sheets can be used for protective barriers. Aluminum is a lightweight and durable material that offers excellent strength and corrosion resistance. It is commonly used in various applications where protection is required, such as construction sites, industrial facilities, and military installations. Aluminum sheets can be easily fabricated and shaped to create sturdy barriers that provide a physical barrier to prevent unauthorized access or to safeguard against potential hazards. Additionally, aluminum is highly versatile and can be combined with other materials, such as glass or steel, to enhance its protective capabilities. Overall, aluminum sheets are a reliable choice for protective barriers due to their strength, durability, and versatility.

- Q: Can aluminum sheets be waterjet cut?

- Yes, aluminum sheets can be waterjet cut. Waterjet cutting is a versatile and efficient method that can be used to cut through a wide range of materials, including aluminum.

Send your message to us

Embossed Aluminum Sheets Houston - Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords