Plates Stainless Steel Hot Rolled 304L NO.1 Finish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

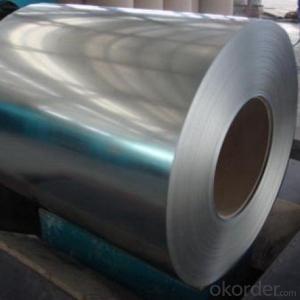

Specifications for Stainless Steel Coils/Sheets:

Prodcut:Stainless Steel Coil

Thinckness: 0.20mm-8.0mm

Width:1000mm, 1219mm(4 feet), 1250mm, 1500mm, 1524mm(5 feet),

1800mm, 2000mm, 2200mm, 2500mm,and customizable

Ni:0.8~1.2% Cu:1.4~1.5% Cr:14

Standard: ASTM, JIS, GB, BS, DIN etc

Grade: 200series&300series&400series

Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

Manufacture technology: cold rolled/hot rolled

Thickness Tolerance: +/-0.1mm

Width Tolerance: +/-10mm

200 Seriers: 201,202

300 Seriers: 301, 304, 304L, 316L, 309, 310S,321

400 Seriers: 410, 410S, 409L,430

Our Service

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: Can stainless steel sheets be used for elevator floors?

- Yes, stainless steel sheets can be used for elevator floors. Stainless steel is a durable and hygienic material that is resistant to corrosion and staining, making it a suitable choice for elevator flooring.

- Q: Are stainless steel sheets suitable for water storage tanks?

- Indeed, water storage tanks can be constructed using stainless steel sheets. Stainless steel possesses a remarkable resistance to corrosion, rendering it an optimal selection for water preservation. Its durability and longevity eliminate the need for frequent upkeep. Moreover, the smooth and non-porous surface of stainless steel sheets inhibits bacterial proliferation, thereby guaranteeing the cleanliness and safety of the stored water for consumption. Furthermore, stainless steel exhibits resistance against UV rays, extreme temperatures, and chemicals, affirming its dependability as a material for water storage tanks.

- Q: Can stainless steel sheets be used for walkways and platforms?

- Stainless steel sheets are capable of being utilized for walkways and platforms. This material, known for its exceptional durability and resistance to corrosion, proves to be ideal for outdoor applications such as walkways and platforms. It has the capacity to endure substantial loads, severe weather conditions, and frequent foot traffic, all while avoiding deterioration and rusting. Moreover, stainless steel possesses a sleek and contemporary appearance that can elevate the visual allure of walkways and platforms. Furthermore, it boasts easy cleaning and maintenance processes, guaranteeing extended lifespan and safety for users.

- Q: How do you cut intricate designs in stainless steel sheets?

- Cutting intricate designs in stainless steel sheets can be a challenging task but can be accomplished through various methods. One common method is using a laser cutting machine. Laser cutting offers precise and clean cuts, allowing for intricate designs to be achieved with ease. The laser beam melts or vaporizes the stainless steel, leaving behind a smooth and precise cut. Another method is using a CNC plasma cutter. This method utilizes a computer-controlled machine that uses a plasma torch to cut through the stainless steel. CNC plasma cutters offer high precision and can handle complex designs. However, the edges may require additional finishing to achieve a smooth and polished look. Waterjet cutting is another option for cutting intricate designs in stainless steel sheets. This method uses a high-pressure jet of water mixed with an abrasive material to cut through the metal. Waterjet cutting is a versatile technique that can handle various thicknesses and designs, producing accurate and detailed results. For smaller projects or intricate designs, a jeweler's saw or a metal nibbler can be used. These handheld tools allow for manual cutting and offer more control over the design. However, they may require more time and effort compared to automated methods. Regardless of the method chosen, it is essential to ensure safety precautions are taken, such as wearing protective gear and following manufacturer's instructions. Additionally, practicing on scrap pieces before working on the final stainless steel sheet can help refine the technique and achieve the desired results.

- Q: How do stainless steel sheets differ from regular steel sheets?

- Stainless steel sheets differ from regular steel sheets primarily in terms of their composition and properties. While regular steel sheets are made of iron and carbon, stainless steel sheets contain additional alloys such as chromium, nickel, and manganese. This composition gives stainless steel sheets a higher resistance to corrosion, making them more durable and suitable for applications where exposure to moisture or harsh environments is a concern. Additionally, stainless steel sheets have a distinctive shiny appearance, known as the stainless steel "finish," which can be maintained even with frequent use.

- Q: Can stainless steel sheets be used for chemical reactors?

- Yes, stainless steel sheets can be used for chemical reactors. Stainless steel is a popular choice for chemical reactors due to its excellent corrosion resistance properties. It is highly resistant to chemical reactions with various substances, making it suitable for handling corrosive chemicals or environments. Stainless steel sheets are also known for their durability, high strength, and ability to withstand high temperatures, making them suitable for use in chemical reactors that may operate under extreme conditions. Additionally, stainless steel is easy to clean and maintain, which is crucial for ensuring the purity and integrity of the reaction process. Overall, stainless steel sheets are widely used in the construction of chemical reactors and are considered a reliable and effective material choice for this application.

- Q: Can stainless steel sheets be used in food processing applications?

- Yes, stainless steel sheets can be used in food processing applications. Stainless steel is a commonly used material in the food industry due to its corrosion resistance, durability, and hygienic properties. It is easy to clean and maintain, making it suitable for food processing equipment such as countertops, work surfaces, and storage containers.

- Q: What are the benefits of using patterned stainless steel sheets in interior design?

- Using patterned stainless steel sheets in interior design offers numerous benefits. Firstly, these sheets provide a unique and modern aesthetic to any space. The patterns etched into the stainless steel can range from geometric designs to intricate motifs, adding a touch of elegance and visual interest to walls, ceilings, or furniture. This can enhance the overall ambiance of a room and make it stand out. Secondly, patterned stainless steel sheets are highly durable and long-lasting. Stainless steel is known for its strength and resistance to corrosion, making it an ideal material for interior design applications. These sheets can withstand daily wear and tear, making them suitable for high-traffic areas such as restaurants, hotels, or public spaces. Moreover, patterned stainless steel sheets are low maintenance. Unlike other materials, stainless steel is easy to clean and does not require special care or regular maintenance. Simple wiping with a damp cloth or using mild cleaning agents is sufficient to keep the sheets looking pristine. This makes them a practical choice for interior design, especially in areas where hygiene is crucial. Additionally, patterned stainless steel sheets offer versatility in design. They can be used in various applications, including wall cladding, room dividers, backsplashes, or even as decorative accents. With a wide range of patterns and finishes available, designers have the freedom to create unique and customized looks to suit any style or theme. Lastly, using patterned stainless steel sheets in interior design is environmentally friendly. Stainless steel is a recyclable material, meaning it can be reused or repurposed without causing harm to the environment. By incorporating sustainable materials into interior design, we contribute to reducing waste and promoting eco-conscious practices. Overall, the benefits of using patterned stainless steel sheets in interior design include their aesthetic appeal, durability, low maintenance requirements, versatility, and environmental friendliness. These sheets offer a practical and visually pleasing solution to elevate the design of any space.

- Q: What is the difference between 304 and 316 stainless steel sheets?

- The main difference between 304 and 316 stainless steel sheets is their composition and corrosion resistance. 304 stainless steel contains 18% chromium and 8% nickel, while 316 stainless steel contains 16% chromium, 10% nickel, and 2% molybdenum. This additional molybdenum in 316 stainless steel improves its corrosion resistance, making it more suitable for use in marine environments or applications exposed to harsh chemicals. Therefore, 316 stainless steel sheets are generally considered more corrosion resistant than 304 stainless steel sheets.

- Q: What factors affect the cost of stainless steel sheets?

- There are several factors that can affect the cost of stainless steel sheets. These include the type and grade of stainless steel, the thickness and size of the sheets, the quantity being purchased, market demand and availability, production and labor costs, and any additional processing or finishing requirements.

Send your message to us

Plates Stainless Steel Hot Rolled 304L NO.1 Finish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords