Hot Rolled Stainless Steel 316L NO.1 Finish

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Payment&Delivery

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Application of Stainless Steel Coils

(1) Boiler heat exchanger,

(2) Chemical industries,

(3) Hardware fields,

(4) Construction material,

(5) Kitchen utensils,

(6) Building construction,

(7) Medical equipment,

(8) chemical tank,

(9) pipe etc

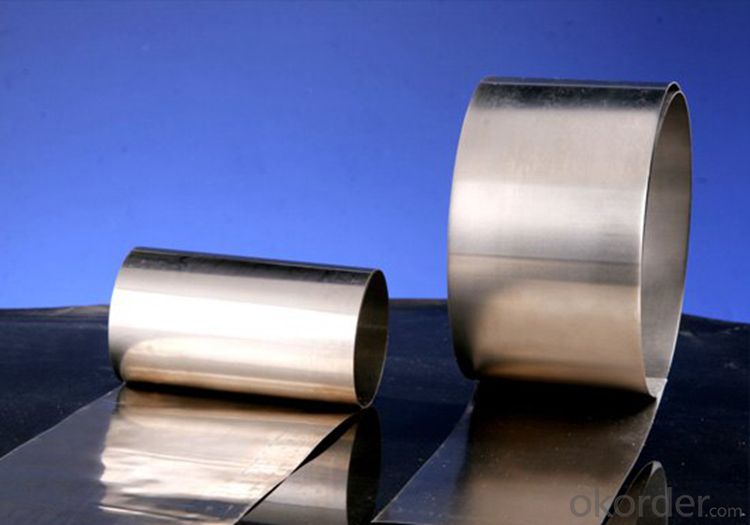

Detail picture for Stainless Steel

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Several processing techniques of colored stainless steel

- Sand blasting, sand blasting can be plated color, but the color of the plating and ordinary plating color difference exists, mainly due to sand blasting particles for emery. The color stainless steel sand blasting plate is made of zirconium beads through the mechanical equipment in the stainless steel plate surface, so that the surface of the board presents small beads, grainy sand surface, forming a unique decorative effect. Uses: mainly used in architectural decoration, elevator decoration, industrial decoration, facilities, decoration and other stainless steel products.

- Q: Are stainless steel sheets suitable for desalination plants?

- Yes, stainless steel sheets are suitable for desalination plants. Stainless steel is highly corrosion resistant, making it ideal for applications in saltwater environments. It can withstand the harsh conditions of desalination plants, including exposure to saltwater, high temperatures, and pressure. Additionally, stainless steel is a durable and hygienic material, making it an excellent choice for desalination plant components such as heat exchangers, pipes, and tanks.

- Q: What are stainless steel sheets made of?

- Stainless steel sheets are made from a type of steel alloy that contains a minimum of 10.5% chromium. The addition of chromium creates a protective layer on the surface of the steel called a passive film, which makes stainless steel resistant to corrosion and staining. In addition to chromium, stainless steel sheets may also contain other elements such as nickel, molybdenum, and nitrogen, which enhance its mechanical properties and corrosion resistance. The specific composition of stainless steel sheets can vary depending on the desired properties and applications.

- Q: How to clean stainless steel plate cleaning?

- If ordinary water leaves some dirt or grease, try adding a mild detergent to the water. The method I used was derived from natural, biodegradable detergent and found that it removed a little water and missed it, including some oils. If you clean stainless steel pots or cutlery, this is the best way to use them. The food on the cooked food can usually be removed from the pan, soaked in soapy water, and with a mild sponge sponge pad. Don't be impatient to use steel wool, it may scratch stainless steel or leave particles that may rust. Again, remember to rinse and dry the stainless steel after cleaning.

- Q: Welding defects analysis of 1.5mm stainless steel plate

- Arc craterBecause the low-lying and arcing arc part formed in the end of the improper bead.Cause: short welding time of welding wire or electrode, insufficient filling metal.Hazard: 1. Reduce the cross-sectional area of the weld;The crater at incomplete reaction prone to agglomeration or segregation of impurities, so the arc pit often have porosity, slag, crack etc..

- Q: Are stainless steel sheets suitable for welding or fabrication?

- Yes, stainless steel sheets are suitable for welding and fabrication. Stainless steel has excellent weldability, which means it can be easily fused together using various welding techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. It also has good formability, allowing it to be easily shaped and fabricated into different structures or components. Additionally, stainless steel sheets offer high strength and corrosion resistance, making them a popular choice in industries such as construction, automotive, and manufacturing. Overall, stainless steel sheets are a versatile and reliable material for welding and fabrication applications.

- Q: Can stainless steel sheets be used for elevator flooring?

- Yes, stainless steel sheets can be used for elevator flooring. Stainless steel is a popular choice for elevator flooring due to its durability, strength, and resistance to corrosion. It is able to withstand heavy foot traffic and is easy to clean and maintain. Additionally, stainless steel is visually appealing and can add a sleek and modern look to elevators.

- Q: What are the different types of stainless steel alloys used for sheets?

- Sheets can be made from various types of stainless steel alloys, each with its own unique properties and applications. Some commonly used stainless steel alloys for sheets include: 1. Austenitic Stainless Steel: This is the most commonly used type of stainless steel, offering excellent corrosion resistance, high ductility, and good formability. It finds applications in food processing, chemical equipment, and architecture. 2. Ferritic Stainless Steel: Ferritic stainless steel alloys are known for their high resistance to stress corrosion cracking and good thermal conductivity. They are commonly used in automotive exhaust systems, heat exchangers, and appliances. 3. Martensitic Stainless Steel: Martensitic stainless steel alloys are known for their high strength, hardness, and wear resistance. They find applications in cutlery, surgical instruments, and turbine blades. 4. Duplex Stainless Steel: Duplex stainless steel alloys combine the properties of both austenitic and ferritic stainless steels. They offer excellent corrosion resistance, high strength, and good weldability. They are commonly used in oil and gas industry equipment, chemical processing, and marine applications. 5. Precipitation-Hardening Stainless Steel: These alloys can be heat treated and provide high strength, good corrosion resistance, and excellent toughness. They are commonly used in aerospace components, the nuclear industry, and high-performance applications. Each stainless steel alloy has its own specific composition and properties, making it suitable for different applications. Factors such as corrosion resistance requirements, strength requirements, and the environment in which the sheets will be used determine the choice of alloy.

- Q: What is the electrical resistivity of stainless steel sheets?

- The electrical resistivity of stainless steel sheets changes based on the particular grade or alloy composition of the stainless steel. In general, compared to materials like copper or aluminum, stainless steel has a relatively low electrical resistivity. The resistivity may vary from around 6.9 x 10^-7 ohm-meters (Ωm) for austenitic stainless steel to 7.2 x 10^-7 Ωm for ferritic stainless steel. It is worth mentioning that these values are approximate and can slightly differ due to factors like temperature and impurities in the stainless steel.

- Q: Are stainless steel sheets available in different thicknesses?

- Yes, stainless steel sheets are available in different thicknesses.

Send your message to us

Hot Rolled Stainless Steel 316L NO.1 Finish

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords