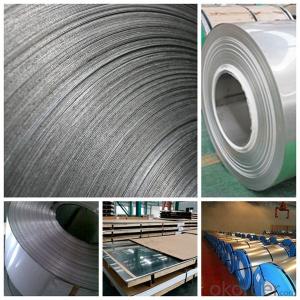

Hot Rolled Stainless Steel Grade 304L NO.1 Finish

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

Payment&Delivery

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Detail picture of Products:

Export Markets

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: What are the pricing options for stainless steel sheets?

- The pricing of stainless steel sheets can vary depending on a range of factors. First and foremost, the grade of stainless steel used plays a significant role. Stainless steel is available in various grades, each offering different levels of corrosion resistance and durability. Higher-grade stainless steel sheets generally come at a higher price. Another factor that influences pricing is the thickness and size of the sheets. Thicker and larger stainless steel sheets tend to be more expensive due to the increased amount of raw material required and the additional processing involved. Moreover, the finish of the stainless steel sheets can also impact the pricing. Different finishes, such as brushed, mirror, or matte, are available for stainless steel sheets. Finishes that necessitate more extensive processing and polishing may come at a higher cost. Additionally, market conditions, including the supply and demand for stainless steel, can affect pricing. Prices can fluctuate based on factors such as raw material costs, production capacity, and global economic conditions. Furthermore, it is crucial to consider the supplier or manufacturer from whom you are purchasing the stainless steel sheets. Different suppliers may offer varying pricing options based on their overhead costs, production capabilities, and market positioning. To summarize, the pricing options for stainless steel sheets are influenced by factors such as grade, thickness, size, finish, market conditions, and the supplier. It is advisable to conduct thorough research and compare prices from different sources to find the most suitable option for your specific requirements.

- Q: Are stainless steel sheets resistant to organic acids?

- Yes, stainless steel sheets are generally resistant to organic acids.

- Q: How do you prevent fingerprints or smudges on stainless steel sheets?

- There are several effective measures you can take to prevent fingerprints or smudges on stainless steel sheets: 1. Regularly wipe down the stainless steel surface with a soft microfiber cloth. Microfiber is great at attracting and trapping dirt, dust, and oils without leaving streaks or smudges. 2. Use warm soapy water to gently clean the stainless steel surface. Mix a small amount of mild dish soap with warm water, then rinse thoroughly and dry with a clean towel. This method effectively removes grease, fingerprints, and smudges. 3. Consider investing in stainless steel cleaners that are specifically formulated to remove fingerprints and smudges. Follow the instructions on the product for best results. 4. Apply a stainless steel protective coating or sealant to create a thin, invisible barrier that repels fingerprints and smudges. Follow the manufacturer's instructions for application and reapply as needed. 5. Avoid using abrasive cleaners, scrub brushes, steel wool, or harsh chemicals that can damage the protective layer of stainless steel. Stick to non-abrasive cleaning methods and tools to maintain the integrity of the surface. 6. Handle stainless steel sheets with care by using clean hands or wearing gloves to prevent the transfer of oils or dirt. Avoid dragging objects across the surface, as this can cause scratches and make it more susceptible to smudging. By incorporating these measures into your cleaning routine and handling practices, you can effectively minimize fingerprints and smudges on your stainless steel sheets, keeping them clean and pristine.

- Q: What is the width range available for stainless steel sheets?

- The width range available for stainless steel sheets can vary depending on the supplier, but it typically ranges from 36 inches to 72 inches.

- Q: Are stainless steel sheets suitable for chemical storage tanks?

- Yes, stainless steel sheets are suitable for chemical storage tanks. Stainless steel is known for its corrosion resistance and durability, making it an excellent choice for storing various chemicals. It is resistant to many corrosive substances, including acids, alkalis, and solvents, which are commonly stored in chemical storage tanks. Stainless steel sheets also have a high strength-to-weight ratio, allowing for the construction of tanks that can withstand the pressure and weight of the chemicals. Additionally, stainless steel is easy to clean and maintain, making it a hygienic option for storing chemicals. Overall, stainless steel sheets are a reliable and suitable material for chemical storage tanks.

- Q: Can stainless steel sheets be used in chemical processing plants?

- Yes, stainless steel sheets are commonly used in chemical processing plants due to their excellent corrosion resistance and high strength properties, making them suitable for handling various chemicals and harsh environments.

- Q: What is the electrical resistivity of stainless steel sheets?

- The electrical resistivity of stainless steel sheets changes based on the particular grade or alloy composition of the stainless steel. In general, compared to materials like copper or aluminum, stainless steel has a relatively low electrical resistivity. The resistivity may vary from around 6.9 x 10^-7 ohm-meters (Ωm) for austenitic stainless steel to 7.2 x 10^-7 Ωm for ferritic stainless steel. It is worth mentioning that these values are approximate and can slightly differ due to factors like temperature and impurities in the stainless steel.

- Q: Can stainless steel sheets be used for outdoor signage or billboards?

- Yes, stainless steel sheets can be used for outdoor signage or billboards. Stainless steel is a highly durable material that is resistant to corrosion, rust, and fading, making it ideal for outdoor applications. It can withstand harsh weather conditions, such as rain, snow, and UV exposure, without losing its integrity. Stainless steel sheets also offer a sleek and modern appearance, which can enhance the visual appeal of outdoor signage or billboards. Additionally, stainless steel can be easily fabricated and cut into various shapes and sizes, allowing for customization and creativity in design. Overall, stainless steel sheets are a reliable and long-lasting choice for outdoor signage or billboards.

- Q: How do you determine the best thickness of stainless steel sheet for a specific application?

- To determine the best thickness of stainless steel sheet for a specific application, several factors need to be considered. Firstly, the intended use of the stainless steel sheet is crucial. Different applications require different levels of strength, durability, and resistance to corrosion. For example, if the sheet will be used in a high-stress environment or exposed to harsh chemicals, a thicker gauge stainless steel sheet would be suitable to ensure sufficient strength and corrosion resistance. Secondly, the size and dimensions of the application should be taken into account. Larger structures or components may require thicker stainless steel sheets to maintain structural integrity and prevent deformation under load. Conversely, smaller or more delicate applications may benefit from thinner sheets to reduce weight and improve flexibility. Moreover, considering the expected lifespan and maintenance requirements is essential. Thicker stainless steel sheets generally offer greater longevity and can withstand more wear and tear. However, if the application requires frequent cleaning or maintenance, a thinner sheet may be more practical. Additionally, budgetary constraints should be taken into consideration. Thicker stainless steel sheets tend to be more expensive due to the increased material cost and manufacturing complexity. Balancing the desired performance with available resources is crucial to determine the most cost-effective thickness. Lastly, consulting industry standards, guidelines, and experts can provide valuable insights. Various industries have specific requirements for stainless steel sheet thickness based on their experiences and safety standards. Engaging with professionals can help to ensure the chosen thickness meets the necessary specifications and regulations. In summary, determining the best thickness of stainless steel sheet for a specific application involves considering the intended use, size, expected lifespan, maintenance requirements, budget, and seeking guidance from industry experts. By carefully evaluating these factors, one can make an informed decision to select the most suitable thickness for their particular needs.

- Q: Can stainless steel sheets be used for water filtration systems?

- Certainly, water filtration systems can make use of stainless steel sheets. Due to their outstanding corrosion resistance and durability, stainless steel is widely employed in water filtration. It possesses the ability to withstand high pressure, temperature fluctuations, and exposure to various chemicals, rendering it suitable for prolonged use in water filtration applications. Moreover, the smooth surface of stainless steel sheets facilitates effortless cleaning and prevents the accumulation of bacteria and other impurities. Furthermore, stainless steel is a non-reactive material, guaranteeing the absence of any harmful substances in the filtered water and ensuring its safety for consumption. In conclusion, stainless steel sheets are a dependable and efficient choice for water filtration systems.

Send your message to us

Hot Rolled Stainless Steel Grade 304L NO.1 Finish

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords