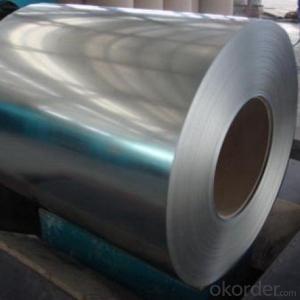

Hot Rolled Stainless Steel 304L NO.1 Finish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Specifications for Stainless Steel Coils/Sheets:

Type | 200 series,300 series,400 series |

Thickness | 1.8-8.0mm |

Widthness | 1000/1219/1500mm |

Technique | Hot Rolled/Cold Rolled |

Coil Weight | About 20 Tons |

Finish | NO.1/NO.2B |

Place of Origin | Made in China |

MOQ | 18 ton |

Color | Black,Mirror Finished |

Standard | ASTM, JIS, GB, BS, DIN etc |

Exporting countries | Peru,India,Pakistan,Singpore,Vietnam,South Korea,Malaysia etc. |

After-sales service | Factory Inspection |

Certifications | ISO,SGS |

Packaging | Standard export packing or following customer's demand |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Payment&Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Application of Stainless Steel Coils

(1)Boiler heat exchanger,

(2)Chemical industries,

(3)Hardware fields,

(4)Construction material,

(5)Kitchen utensils,

(6)Building construction,

(7)Medical equipment,

(8)Chemical tank,

(9)Pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Are stainless steel sheets suitable for chemical storage vessels?

- Indeed, stainless steel sheets prove to be a fitting option for chemical storage vessels. Renowned for its remarkable resistance to corrosion, stainless steel emerges as an optimal substance for the containment of diverse chemicals. It withstands the majority of acids, alkalis, and solvents, thereby guaranteeing the vessel's integrity and averting any potential chemical interactions or seepages. Furthermore, stainless steel boasts exceptional durability and an ability to endure elevated temperatures and pressures, rendering it an appropriate choice for an extensive array of chemical storage purposes.

- Q: Can stainless steel sheets be used for decorative purposes?

- Yes, stainless steel sheets can definitely be used for decorative purposes. Stainless steel is known for its sleek and modern appearance, making it a popular choice for various decorative applications. It is often used in interior design, architecture, and even art installations. Stainless steel sheets can be customized to create unique patterns, textures, and finishes, making them suitable for creating eye-catching and visually appealing decorative elements. Additionally, stainless steel is highly durable, corrosion-resistant, and easy to maintain, making it a practical choice for both indoor and outdoor decorative applications.

- Q: How do you measure the thickness of stainless steel sheets?

- There are multiple methods available for measuring the thickness of stainless steel sheets. One commonly used approach involves the utilization of a caliper, which is a precision measuring tool. By placing the jaws of the caliper on both sides of the sheet and tightening them until contact is made, the thickness can be directly measured. The reading on the caliper will provide an indication of the sheet's thickness. Alternatively, a more accurate method for measuring very thin sheets is through the use of a micrometer, which functions similarly to a caliper. By employing a spindle and anvil, the micrometer can provide precise measurements of thickness. This method is frequently employed in industries where accuracy is of utmost importance, such as manufacturing and engineering. In the absence of a caliper or micrometer, a simple ruler or tape measure can be utilized. Although this method may not provide the same level of accuracy as specialized tools, it can still offer a rough estimate of the thickness. By measuring the height of the sheet, assuming it is uniformly thick, one can infer the sheet's thickness. It is worth noting that the appropriate measurement tool depends on the thickness of the stainless steel sheet. Micrometers and calipers are best suited for measuring thinner sheets, while thicker sheets may require more specialized instruments like ultrasonic thickness gauges. In conclusion, the thickness of stainless steel sheets can be measured using various methods, including calipers, micrometers, rulers, or tape measures. The choice of tool depends on the desired level of accuracy and the thickness of the sheet being measured.

- Q: What are the different surface finishes available for stainless steel sheets?

- There are several different surface finishes available for stainless steel sheets, each offering unique characteristics and aesthetics. 1. No.1 Finish: This is the most common and widely used finish for stainless steel sheets. It has a rough, dull appearance with visible grain lines. No.1 finish is obtained by hot rolling the stainless steel and is suitable for applications where a rough finish is acceptable. 2. No.2B Finish: This finish is obtained by cold rolling the stainless steel and then annealing it, resulting in a smooth, reflective surface with a slightly dull appearance. It is commonly used for kitchen appliances, architectural accents, and decorative purposes. 3. No.2D Finish: Similar to No.2B finish, No.2D finish is achieved by cold rolling and annealing the stainless steel. However, it has a smoother and shinier appearance, making it suitable for applications requiring a more polished look. 4. No.3 Finish: Also known as a brushed finish, No.3 finish is achieved by polishing the stainless steel with abrasive belts or brushes. It has a unidirectional satin-like appearance, often used for decorative purposes in architecture and interior design. 5. No.4 Finish: This finish is obtained by polishing the stainless steel with finer abrasive belts or brushes than No.3 finish. It has a more refined and smoother appearance, often used for decorative purposes, such as elevator panels, kitchen equipment, and automotive trim. 6. No.8 Finish: Also known as a mirror finish, No.8 finish is achieved by polishing the stainless steel with progressively finer abrasive materials until a highly reflective surface is obtained. It provides a glossy, mirror-like appearance, ideal for architectural and decorative applications. 7. Hairline Finish: Hairline finish is achieved by mechanically polishing the stainless steel surface with a fine abrasive material. It creates a subtle, linear pattern with a matte appearance, commonly used for architectural accents, appliances, and decorative items. These are some of the most common surface finishes available for stainless steel sheets. The choice of finish depends on the desired aesthetics, functionality, and application requirements.

- Q: Can stainless steel sheets be polished or brushed?

- Stainless steel sheets have the ability to undergo both polishing and brushing procedures. Polishing these sheets necessitates the utilization of abrasive compounds to eliminate any surface blemishes or scratches, ultimately producing a sleek and reflective appearance. Conversely, brushing stainless steel sheets involves the usage of abrasive pads or brushes to craft a textured design or finish. This technique generates a brushed look featuring delicate parallel lines, which may be oriented either horizontally or vertically. Both polishing and brushing methods serve to heighten the visual allure of stainless steel sheets while concurrently bolstering their resistance against corrosion.

- Q: What are the different types of stainless steel alloys used for sheets?

- There are various types of stainless steel alloys used for sheets, each with its own unique properties and applications. Some of the commonly used stainless steel alloys for sheets include: 1. Austenitic Stainless Steel: This type of stainless steel is the most commonly used and offers excellent corrosion resistance, high ductility, and good formability. It is often used in food processing, chemical equipment, and architectural applications. 2. Ferritic Stainless Steel: Ferritic stainless steel alloys are known for their high resistance to stress corrosion cracking and good thermal conductivity. They are commonly used in automotive exhaust systems, heat exchangers, and appliances. 3. Martensitic Stainless Steel: Martensitic stainless steel alloys are known for their high strength, hardness, and wear resistance. They are commonly used in cutlery, surgical instruments, and turbine blades. 4. Duplex Stainless Steel: Duplex stainless steel alloys combine the properties of both austenitic and ferritic stainless steels. They offer excellent corrosion resistance, high strength, and good weldability. They are commonly used in oil and gas industry equipment, chemical processing, and marine applications. 5. Precipitation-Hardening Stainless Steel: These alloys are heat treatable and offer high strength, good corrosion resistance, and excellent toughness. They are commonly used in aerospace components, nuclear industry, and high-performance applications. Each type of stainless steel alloy has its own specific composition and properties, making them suitable for different applications. The choice of alloy depends on factors such as corrosion resistance requirements, strength requirements, and the environment in which the sheets will be used.

- Q: Are stainless steel sheets resistant to high temperatures?

- Yes, stainless steel sheets are generally resistant to high temperatures.

- Q: Are stainless steel sheets resistant to saltwater corrosion?

- Yes, stainless steel sheets are highly resistant to saltwater corrosion. Stainless steel is known for its exceptional corrosion resistance, making it an ideal material for applications exposed to saltwater environments. The chromium content in stainless steel forms a protective oxide layer on the surface, which acts as a barrier against corrosion. This oxide layer prevents the steel from coming into direct contact with saltwater, thereby reducing the risk of corrosion. Additionally, stainless steel grades such as 316 and 316L are specifically designed to offer better resistance to saltwater corrosion, making them even more suitable for marine applications. Overall, stainless steel sheets are a reliable choice for saltwater environments due to their excellent corrosion resistance properties.

- Q: Are stainless steel sheets suitable for high-temperature applications?

- Yes, stainless steel sheets are suitable for high-temperature applications. They have excellent heat resistance properties and can withstand elevated temperatures without losing their strength or structural integrity.

- Q: What are the different types of stainless steel sheet finishes for industrial applications?

- There are several different types of stainless steel sheet finishes that are commonly used in industrial applications. These finishes are designed to provide different levels of durability, corrosion resistance, and aesthetics. 1. No. 1 Finish: This is a hot-rolled, annealed, and pickled finish that is characterized by a dull, rough surface. It is commonly used in applications where a smooth surface is not required, such as structural components or where appearance is not a major concern. 2. No. 2B Finish: This is a smooth, moderately reflective finish that is achieved by cold rolling, annealing, and pickling. It is commonly used for applications that require a good balance between corrosion resistance and appearance, such as kitchen appliances, architectural components, and food processing equipment. 3. No. 4 Finish: This is a brushed finish that is achieved by polishing with abrasive belts or brushes. It has a matte appearance and is often used in applications where a decorative finish is desired, such as furniture, elevator panels, and signage. 4. No. 8 Finish: Also known as mirror finish, this is the most reflective finish available for stainless steel sheets. It is achieved by polishing with progressively finer abrasives until a highly reflective surface is obtained. This finish is commonly used in applications where a high level of reflectivity and a decorative appearance are desired, such as architectural accents, automotive trims, and decorative items. 5. BA Finish: This is a bright annealed finish that is achieved by annealing in a controlled atmosphere furnace. It has a smooth, highly reflective surface and is commonly used in applications where a mirror-like finish is desired, such as decorative items, reflectors, and light fixtures. These are just a few of the most common stainless steel sheet finishes used in industrial applications. Each finish has its own unique properties and is suitable for different purposes, so it is important to carefully consider the requirements of the specific application when selecting a finish.

Send your message to us

Hot Rolled Stainless Steel 304L NO.1 Finish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords