8 Oz Geotextile Plastic Grass Paver Geocell Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Plastic Grass Paver Geocell:

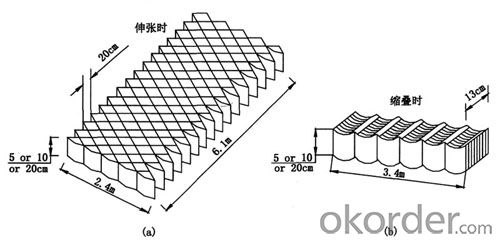

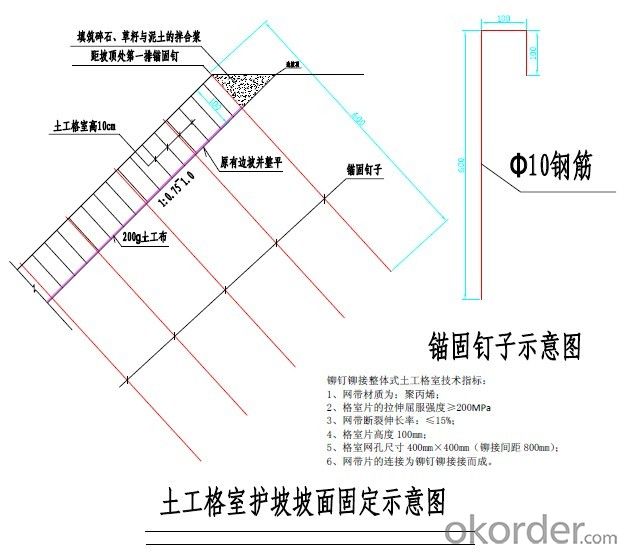

High Quality HDPE Plastic Gravel Stablizer / Soil Stabiliser Geocell is made from HDPE (high-molecular polyethylene) with fiber and age resistor,using high pressure to inject plastic to form bee nest-like shaped shell, with stereo space and support level. It's widely used in parking lot, fire exit, fire climbing surface, pavement etc. Since it can protect the grass, it is also known as the green grass protection mat.

Main Features of Plastic Grass Paver Geocell:

to stable the bed of railway and road

to bear the bed of road

to bear the loading dykes and walls

to administer shallow water and river

to support pipeline and sewer

to prevent landslide and to be used as compound walls to support loading

to be used in dependent walls,wharfs and bank and so on

to govern sand,beach,river bank and riverbed

Specifications of Plastic Grass Paver Geocell:

Geocell welding mold-digit | HJM-11 | HJM-14 | HJM-15 | HJM-18 | HJM-22 |

No.of welding heads | 11 unit | 14 unit | 15 unit | 18 unit | 22 unit |

Max. Power | 28.6KW | 36.4KW | 36.6KW | 46.8KW | 57.2KW |

Ultrasonic Vibrating Power | 16.5KW | 21KW | 23KW | 27KW | 33KW |

SIZE OF THE EQUIPMENT (L*W*H)(M | 6.5*1.89*2.26 | 7*1.89*2.26 | 8*1.89*2.26 | 8*1.89*2.26 | 9*1.89*2.26 |

WEIGHTNESS | 5TONS | 5.5TONGS | 5.8TONS | 6TONS | 6.5TONS |

POWER | AC380V N 50-60HZ | ||||

AIR PRESS | 0.6~0.9MPa | ||||

AIR COMPESSOR DISPLACEMENT | ≥2.5~3.0/min | ||||

VOLOUM OF AIR COMPRESSOR AIR STORAGE | 1.5~2.0M3 | 2.5~3.0M3 | |||

WELDING DISTANCE SCOPE | 220-1000mm | ||||

GEOCELL STRIP WIDTH | 220MM MAX (ADJUSTABLE ACCORDING TO THE SIZE OF WELDING HEAD) | ||||

DAILY OUTPUT (REF) | 4500SQM | 4800SQM | 5000SQM | 5200SQM | 8000SQM |

IMages of Plastic Grass Paver Geocell:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How do geotextiles help with filtration in stormwater management?

- Geotextiles help with filtration in stormwater management by acting as a barrier that allows water to pass through while trapping sediment and other pollutants. This helps to prevent the contamination of water bodies and promotes the retention of clean water within the stormwater management system.

- Q: What are the different geotextile filter criteria?

- The different geotextile filter criteria include permeability, retention, durability, and compatibility. Permeability refers to the ability of the geotextile to allow water to pass through while retaining soil particles. Retention is the capability of the geotextile to prevent soil particles from passing through, ensuring effective filtration. Durability assesses the geotextile's resistance to physical and chemical degradation over time. Compatibility refers to the geotextile's compatibility with the soil and other materials it is in contact with, ensuring long-term effectiveness.

- Q: What are the key considerations for geotextile installation in high wind areas?

- The key considerations for geotextile installation in high wind areas include selecting a high-strength geotextile material, ensuring proper anchoring and securing methods, evaluating the site's wind load potential, and implementing effective quality control measures to ensure the installation's durability and long-term performance.

- Q: Application of composite geotextile

- Water conservancy projects: seawall, river embankment, lake embankment project; reservoir reinforcement project; reclamation project; flood control and rescue. Highway and railway engineering: soft foundation reinforcement treatment; slope protection; road anti-reflective crack structure layer; drainage system; green isolation zone. Electrical engineering: nuclear power plant basic engineering; thermal ash dam project; hydropower project.

- Q: How to build a good 12 by 24 brick wall

- 12 by 24

- Q: How do geotextiles aid in the reduction of differential settlement?

- Geotextiles aid in the reduction of differential settlement by providing a stable and uniform base for the construction of roads, embankments, and foundations. They distribute the load more evenly, improving soil stability and preventing differential settlement, which occurs when different areas of the soil settle at different rates, leading to uneven surfaces and potential structural damage.

- Q: Garage top back to the soil before the drainage board geotextile take what role

- The top surface of the drainage board glue a layer of geotextile filter to prevent the passage of soil particles, so as to avoid drainage channel obstruction of the drainage channel, said white is to do a filter layer, the water discharged to the designated location, the traditional process is Block ah, stone ah, what do the water layer, and now with the drainage board is not the reason for the stone is the drainage board is plastic, light weight, can reduce the load of the building. Manufacturers of drainage board geotextile waterproof board

- Q: Can geotextiles be trampled on the ground?

- Trampled on a long time to step on the geotextile will have an impact, geotextile main function is anti-penetration

- Q: What is the difference between woven and non-woven geotextiles?

- Woven geotextiles are made by weaving continuous individual yarns together, creating a strong and durable fabric. On the other hand, non-woven geotextiles are made by bonding or felting together synthetic fibers, resulting in a fabric that is not as strong or durable as woven geotextiles. Woven geotextiles provide higher tensile strength, better filtration, and are typically used in applications that require greater longevity and stability. Non-woven geotextiles, while less durable, are often used for filtration and separation purposes due to their high water flow rates and ability to retain fine particles.

- Q: How do geotextiles improve the performance of geogrids?

- Geotextiles improve the performance of geogrids by providing additional reinforcement and stability. They act as a separation layer, preventing soil particles from migrating through the geogrids and reducing the potential for clogging. Geotextiles also enhance the drainage capacity of geogrids by allowing water to flow freely through the system, preventing the accumulation of water and reducing the risk of soil erosion. Moreover, geotextiles can increase the overall strength and load-bearing capacity of geogrids, making them more efficient in stabilizing soil and improving the overall performance of geogrid applications.

Send your message to us

8 Oz Geotextile Plastic Grass Paver Geocell Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords