8 Oz Nonwoven Geotextile Fabric - High Tensile Strength Polypropylene Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Brief Introduction of Polypropylene Geotextile

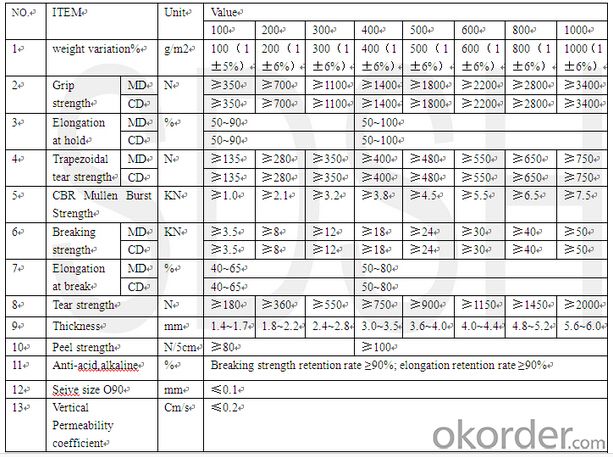

Material:Polypropylene

Weight:100~800g

Width:1~6m

Length:30~100m;or as your request

2,Feature of Polypropylene Geotextile

Good flexibility,permeability,filtration,separation and easy for construction,acid-proof, alkali-proof, sun-proof, mildew-proof and worm-proof. excellent water permeability, high tensile strength and shock strength, non-toxic and harmless.

3,Package of Polypropylene Geotextile

Packed in rolls or as per your request

4,Application of Polypropylene Geotextile

Used in the area of highway, airport, railway,dam, reclamation for filtration, separation drainage and protection. Our product can be used to keep soil from losing, collapsing, shocking and stable the base. Because of good wind resistant and frost resistant, the geotextile can also be used as protection of trees in winter.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of geo textile and geo bag etc. We have exported this product to Amereica, Europe and South East Asia. Customized product is also available based on your detailed requirements.

2> What's the MOQ ?

We kindly recommend 1x40'HQ as the price would be economical based on large loading quantity.

3>How long can we receive the product after purchase?

It takes about 1 to 2 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: What are the advantages of using geotextiles in waste containment systems?

- Geotextiles offer several advantages in waste containment systems. Firstly, they act as a barrier, preventing the migration of pollutants and contaminants into the surrounding environment. This helps to protect groundwater and nearby ecosystems from potential harm. Additionally, geotextiles enhance the stability and structural integrity of waste containment systems, reducing the risk of failure or leakage. They also aid in the filtration and drainage of liquids, allowing for proper waste management and preventing the buildup of excess moisture. Overall, geotextiles provide an effective and environmentally-friendly solution for waste containment, ensuring safer disposal of waste materials.

- Q: Production of 1 square meter 100g geotextile consumption of polyester fiber how many kilograms

- Theoretically is 100g, I am specializing in the production of geotechnical materials, wish smooth

- Q: How do geotextiles improve the performance of slopes?

- Geotextiles improve the performance of slopes by providing reinforcement and stability. They help to prevent soil erosion by acting as a barrier against water flow and sediment movement. Additionally, geotextiles assist in distributing the load evenly across the slope, reducing the risk of structural failure.

- Q: Geotextile geotextile geotextile construction geotextile specific application

- Nonwovens is a major category of textiles, geotechnical construction is its use on the one hand, in this field people call it geotextile. Many types of non-woven fabrics, the specific technical indicators to be determined according to the actual species. Generally measure its raw materials, weight, moisture permeability, tear strength, bursting strong, etc., insulation, moisturizing. Scope: ⒈ water conservancy project dam and slope protection of the filter, channel isolation, anti-seepage. ⒉ road, railway, airport runway foundation isolation, filter, drainage, soil slope, retaining wall and road reinforcement, drainage. ⒊ port engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage. ⒋ landfill, thermal power plant ash dam, mine tailings dam isolation, seepage control. ⒌ polyester long fiber anti-sticking acupuncture geotextile has been applied throughout the field of infrastructure construction, and gradually applied to a wider range of areas.

- Q: How do geotextiles help with reinforcement of geogrid reinforced embankments?

- Geotextiles help with reinforcement of geogrid reinforced embankments by acting as a separation layer between the geogrid and the embankment material. They prevent the intermixing of soil particles, enhance the load distribution, and provide additional stability to the embankment. Additionally, geotextiles improve the overall performance of the geogrid by reducing the potential for clogging and maintaining its long-term design strength.

- Q: What are the key factors affecting the puncture resistance of geotextiles?

- The key factors affecting the puncture resistance of geotextiles include the thickness and density of the fabric, the type and strength of the fibers used, the presence of any surface coating or treatment, and the overall construction and quality of the geotextile. Additionally, the puncture resistance can also be influenced by environmental factors such as temperature, moisture, and exposure to chemicals or UV radiation.

- Q: Can geotextiles be used in erosion control in agricultural fields?

- Yes, geotextiles can be used effectively in erosion control in agricultural fields. Geotextiles act as a physical barrier that prevents soil erosion by stabilizing the soil and reducing the impact of water flow. They can be used to reinforce slopes, control sedimentation, and provide long-term soil stabilization. Additionally, geotextiles are permeable, allowing water to pass through while retaining soil particles, making them an ideal solution for erosion control in agricultural fields.

- Q: what do you mean nonwoven geotextiles ???

- please refer the folowing url to know all the details about non woven geo textiles

- Q: Geotextile how much money

- Specifications of different quality prices ranging from geotextiles from November last year to the current price rose too much

- Q: What are the different geotextile installation techniques in separation?

- There are several different geotextile installation techniques used in separation, including direct placement, trench installation, and overlapping. Direct placement involves laying the geotextile directly on the ground surface, while trench installation involves placing the geotextile in a trench dug along the separation area. Overlapping is another technique, where multiple layers of geotextile are overlapped to form a continuous barrier. These installation techniques help to prevent the mixing of different soil layers and provide effective separation between different materials.

Send your message to us

8 Oz Nonwoven Geotextile Fabric - High Tensile Strength Polypropylene Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords