Precio Geotextil High Tensile Non Woven Polypropylene Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of High Tensile Non Woven Polypropylene Geotextile Description:

High Tensile Non Woven Polypropylene Geotextile Made from PP (polypropylene) short fiber by nonwoven needle punched manufacturing process, it has isolation, filtration, drainage, reinforcement, protection and maintenance etc. function.

Main Features of the Non Woven Polyester Geotextile :

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment.

It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

2) Filament geotextile:

Filament geotextile has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects.

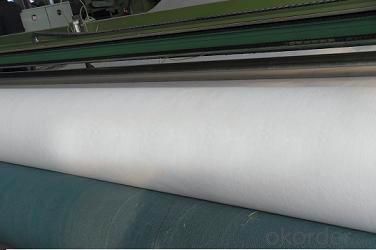

Non Woven Polyester Geotextile Images

Non Woven Polyester Geotextile Specification:

1) Weight / Mass: 100g/m2-1500g/m2 .

2) Width: Within 8 m (1m-8m as request ).

3) Length: 50m-100m/roll (as request).

4) Material: PP / PET .

5) Certificate: CE/ISO9001/ISO14001

6) Manufacturing method: nonwoven / woven.

| c | Item | Value | Note | ||||||||||

| 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |||

| 1 | Weight Variation(%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

| 2 | Thickness(mm)≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3 | 3.3 | 3.6 | 4.1 | 5 | |

| 3 | Width Variation% | -0.5 | |||||||||||

| 4 | Breaking Strength( KN/m)≥ | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 13 | 14 | 16 | 19 | 25 | MD and TD |

| 5 | Elongation at break% | 25-100 | |||||||||||

| 6 | CBR Mullen Burst Strength KN≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4 | |

| 7 | Sieve Size O90(mm) | 0.07-0.2 | |||||||||||

| 8 | Vertical Permeability Coefficient cm/s | K×(10-1-10-3) | K=1.0-9.9 | ||||||||||

| 9 | Tearing Strength KN≥ | 0.08 | 0.12 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.6 | MD and TD |

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Are geotextiles commonly used in rainwater harvesting systems?

- Yes, geotextiles are commonly used in rainwater harvesting systems. Geotextiles act as a filtration layer, preventing the entry of debris and sediment into the harvesting system while allowing water to pass through. This helps to maintain the quality of collected rainwater and prevents clogging or damage to the system.

- Q: How do geotextiles contribute to soil reinforcement?

- Geotextiles contribute to soil reinforcement by providing a stable and durable layer that helps to distribute loads and reduce soil erosion. They act as a barrier against the movement of soil particles, preventing soil erosion and maintaining the stability of the soil structure. Additionally, geotextiles can improve the tensile strength of the soil, increasing its load-bearing capacity and overall stability.

- Q: How do geotextiles help with sediment control in water bodies?

- Geotextiles help with sediment control in water bodies by acting as a barrier that filters out sediment and other pollutants from entering the water. They are placed in strategic locations to prevent erosion and retain sediment, allowing cleaner water to pass through. Additionally, geotextiles promote vegetation growth, which further aids in sediment control by stabilizing the soil and reducing erosion.

- Q: How do geotextiles help with load distribution in bridge approach fills?

- Geotextiles help with load distribution in bridge approach fills by providing a reinforcement layer that distributes the load from the bridge structure more evenly across the fill material. This helps to prevent differential settlement and ensures the stability and durability of the bridge approach.

- Q: Can geotextiles be used in mine tailings dewatering applications?

- Yes, geotextiles can be used in mine tailings dewatering applications. Geotextiles are commonly used in mining operations to separate and filter solids from liquids, including in the dewatering of mine tailings. They can effectively retain fine particles while allowing water to pass through, aiding in the process of dewatering and facilitating the management and disposal of mine tailings.

- Q: What are the factors that affect the effectiveness of geotextiles in erosion control?

- Some factors that affect the effectiveness of geotextiles in erosion control include the type and quality of the geotextile material, the installation method, the slope gradient and soil type, the amount and intensity of rainfall, and the presence of vegetation or vegetation establishment.

- Q: How do geotextiles help with reinforcement of geotextile tubes?

- Geotextiles help with the reinforcement of geotextile tubes by providing stability and strength. They act as a barrier, preventing soil erosion and maintaining the shape and integrity of the tube. The geotextile acts as a filter, allowing water to pass through while retaining soil particles, which helps in soil consolidation and prevents the tube from collapsing. Additionally, geotextiles distribute stress evenly across the tube, enhancing its load-bearing capacity and overall performance.

- Q: How do geotextiles help in erosion control?

- Geotextiles help in erosion control by providing a physical barrier that stabilizes soil and prevents its movement. These permeable fabrics allow water to pass through while trapping soil particles, thereby reducing surface erosion. Additionally, geotextiles improve soil stability by reinforcing it, preventing its displacement and aiding in the establishment of vegetation.

- Q: Are geotextiles suitable for use in contaminated soil remediation projects?

- Yes, geotextiles are suitable for use in contaminated soil remediation projects. Geotextiles can act as a barrier to prevent the spread of contaminants, while also allowing water and air to pass through. They can be used to separate clean and contaminated soils, provide stability to slopes, and enhance the effectiveness of other remediation techniques such as phytoremediation or soil vapor extraction. Additionally, geotextiles are durable and cost-effective, making them a practical choice for soil remediation projects.

- Q: Waterproof geotextile market demand prospects?

- Supply geotextile, geomembrane, composite geomembrane and other geotechnical materials. Market prospects are excellent. Geotechnical material manufacturers to answer your questions

Send your message to us

Precio Geotextil High Tensile Non Woven Polypropylene Geotextile for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords