Non Woven Geotextile Fabric 8 Oz for Dam with CE Plastic Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

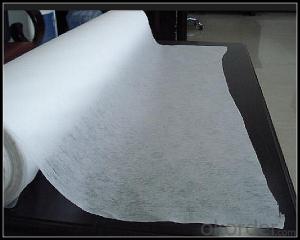

Description Of Plastic Woven Geotextile:

Plastic woven film yarn geotextile is a kind of geotextile made by extruding, cuting film,stretching to film yarn (monofilament, split-film yarn) ,weaving.

Main Features of Plastic Woven Geotextile:

1.Engineered to provide high strength and high elongation at break to ensure excellent resistance to damage during construction.

2.Manufactured from high tenacity UV stabilised virgin polypropylene or polyester fibers which have been heavily drawn to ensure excellent long term durability in all soil types.

3.Manufactured using a randomly orientated web to provide completely isotropic properties,ensuring that high strength is not limited to a single direction.

4.Excellent uniformity with high permeability and low pore size for soil filtration.

5.Supplied to a maximum width of 6.5mts,ensuring minimum waste over large construction areas.

6.100% polypropylene or polyester staple fibers ,needle punched and random network formation.

7.UV and rot resistant and biological degradation resistant.

Specifications of Plastic Woven Geotextile:

1.woven geotextile(reinforced geotextile)

2.Materials:PP

3.Tensile strength:15~100kn/m

4.Unit weight:100~400g/m2

5.Width:1 ~ 6m

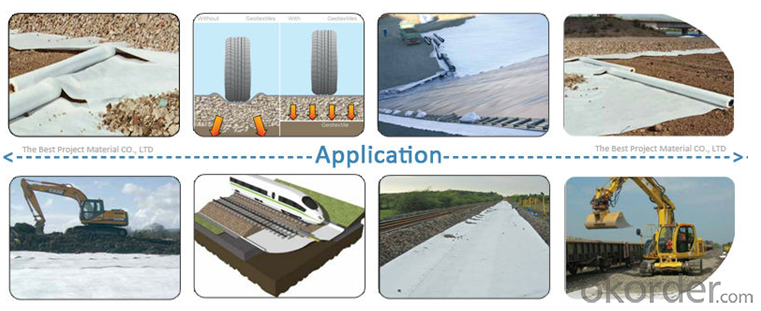

Applications of Plastic Woven Geotextile::

While the nonwoven fabric can be used in almost any stabilization,separation or cushioning application,they are most commonly used in areas that also require filatration.The non woven design of the material provides a higher rate of flow through,making it easier for water to pass through the material.

Some commen uses of the material includes the following:

1.Road stabilization applications

2.Roofs

3.Civil applications

4.Railway work

5.Landfill lining

6.Trenches

7.Dams

8.Fitration under rip rap and rocks

9.Environmental applications

IMages of Plastic Woven Geotextile::

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Artificial lake geotextile practices

- Library and slope with a composite geomembrane all laying, I specialize in the production and construction of geotextile materials

- Q: What are the potential drawbacks of using geotextiles?

- Some potential drawbacks of using geotextiles include the high cost of materials and installation, limited durability in certain environments, potential for clogging due to fine particles, and difficulty in recycling or disposing of used geotextiles. Additionally, improper installation or selection of geotextiles may not provide the desired results, leading to project failure or inefficiency.

- Q: How do geotextiles help with reinforcement of geogrid wall systems?

- Geotextiles help with the reinforcement of geogrid wall systems by acting as a separation and filtration layer. They prevent the mixing of different soil layers, which can compromise the stability of the wall system. Additionally, geotextiles help to distribute the loads evenly across the geogrids, enhancing their strength and overall performance.

- Q: Split silk geotextile and filament geotextile relative price which is cheaper

- Split silk geotextile and filament geotextile relative price which is cheaper

- Q: Are geotextiles suitable for use in gabion walls?

- Yes, geotextiles are suitable for use in gabion walls. They can be used as a filter fabric to prevent soil erosion and improve drainage within the gabion structure. Additionally, geotextiles help to separate different layers of materials, preventing mixing and maintaining the stability of the gabion wall.

- Q: This is a large sample of gravel anti-filter how this project count

- Lack of slope and total length, can not accurately calculate the amount of engineering. Approximate estimates of cross-sectional area, then only a few simple graphics: clay tamping (rectangular), coarse gravel (trapezium), gravel and gravel (zoned plus parallel quadrilateral), geotextile (four sections)!

- Q: The amount of geotextile drained pipe drape

- According to the two sides agreed by the measurement method, such as by the extension of the package or the expansion of the area can be calculated, you can also agreed to package a tube how much money. Generally calculated by the expansion of the area is more reasonable, because the size of the pipeline.

- Q: Can geotextiles be used for reinforcement in retaining walls?

- Yes, geotextiles can be used for reinforcement in retaining walls. Geotextiles are commonly used in retaining wall construction to provide strength, stability, and improved drainage. They help to distribute the load and prevent soil erosion while allowing water to pass through, making them an effective solution for reinforcing and enhancing the performance of retaining walls.

- Q: Can geotextiles be used in coastal erosion control in beach nourishment projects?

- Yes, geotextiles can be used in coastal erosion control in beach nourishment projects. Geotextiles are often employed as a part of a layered system to prevent erosion by stabilizing the beach sediment. They act as a barrier between the beach material and the underlying soil, reducing erosion caused by water movement and wave action. Additionally, geotextiles can help to retain and distribute sand, enhancing beach nourishment efforts and providing long-term protection against coastal erosion.

- Q: What are the maintenance requirements for geotextiles?

- The maintenance requirements for geotextiles generally involve regular inspection and cleaning. Regular inspection helps identify any damage or wear, which can then be repaired or replaced. Cleaning may involve removing any debris or sediment that has accumulated on the geotextiles to maintain their functionality and prolong their lifespan.

Send your message to us

Non Woven Geotextile Fabric 8 Oz for Dam with CE Plastic Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords