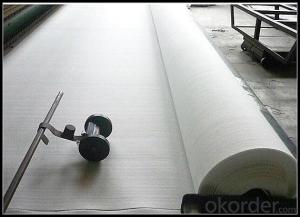

8oz Composites Non Woven Polypropylene Geotextile Fabrics Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Geotextile Specifications

1) Weight / Mass: 100g/m2-1500g/m2

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP / PET

5) Color: Black , white , grey and other color

6) Certificate: CE/ISO9001 , ISO14001

7) Manufacturing method: nonwoven / woven

8) The Biggest geotextile manufacturer/factory in China for many years

1)Geotextile can make the water flow easily, and form a drainage channel in the soil, and then make the liquid and gas out of the soil.

Make use of its pulling resistance and deformation resistance that can strength the soil to reinforce the stability of the construction structure and improve the soil’s quality.

2) Make the focus proliferate, deliver and decompose efficiently and prevent the soil from destruction from outside factor.

3) Prevent the top and bottom layer’s gravel, soil and concrete from mixer.

4) The mesh cannot be plugged easily – for the strain and moving quality of the network that formed by the antitype fiber.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: 500 polypropylene geotextile detection index

- Indicators I have marked, please see 500g that column, if not clear please ask questions in question.

- Q: Can geotextiles be used for reinforcement in asphalt overlays?

- Yes, geotextiles can be used for reinforcement in asphalt overlays. Geotextiles are commonly used to improve the performance and longevity of asphalt overlays by providing reinforcement and mitigating cracking. They help distribute the load and stresses, reduce reflective cracking, and improve the overall structural integrity of the pavement.

- Q: 200g / m2 geotextile how to enter the inspection test

- 200g / m2 geotextile how to enter the inspection test

- Q: What is the purpose of using geotextiles in construction projects?

- The purpose of using geotextiles in construction projects is to improve the stability, durability, and overall performance of the construction site. Geotextiles act as a barrier against soil erosion, provide filtration and drainage capabilities, and enhance soil reinforcement. They also help in the separation of different soil layers, preventing contamination and maintaining the integrity of the project.

- Q: Are geotextiles recyclable?

- Yes, geotextiles are recyclable. They can be processed and converted into new products or materials, reducing waste and promoting a more sustainable approach to construction and environmental protection.

- Q: Where can the general use of geotextile water can be bought

- Lingxian geotextile manufacturers, welcome to visit

- Q: How to determine the nominal breaking strength of filament spunbonded nonwoven geotextile

- You can use a dedicated geotextile strong test machine detected.

- Q: How do geotextiles improve the performance of foundations?

- Geotextiles improve the performance of foundations by providing reinforcement, filtration, and separation functions. They increase the load-bearing capacity of the soil, distribute the load more evenly, and prevent the mixing of different soil layers. Additionally, geotextiles help to drain excess water, control soil erosion, and protect the foundation from potential damage.

- Q: Is it possible to isolate permeated geotextiles and impervious geotextiles?

- Geotextile is permeable, and water, but the soil, from the filter effect, impermeable geotextile is geomembrane composite geotextile composite products, is impermeable and waterproof, I am specializing in the production of geotechnical materials,

Send your message to us

8oz Composites Non Woven Polypropylene Geotextile Fabrics Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords