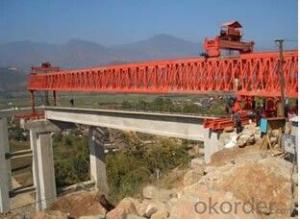

Pier Column Formwork and Dam Formwork

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pier Column Formwork and Dam Formwork

China Formwork Wuxin(Beijing)Import & Export Co., Ltd. ( CFWIE ) is an integrated service supplier of international trade in formwork & scaffolding industry. As a subsidiary of China –Railway Wuxin Group, CFWIE is an overseas business window set up in Beijing. We mainly specializes in import and export international trade of formwork, scaffolding, crane, engineering machinery and other construction equipment.

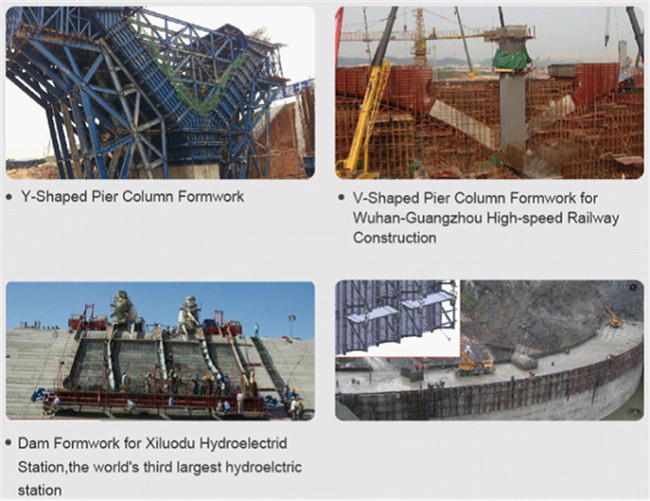

1.Y-Shaped Pier Column Formwork

2.V-Shaped Pier Column Formwork

3.Dam Formwork for xiluodu Hydroelectird Station

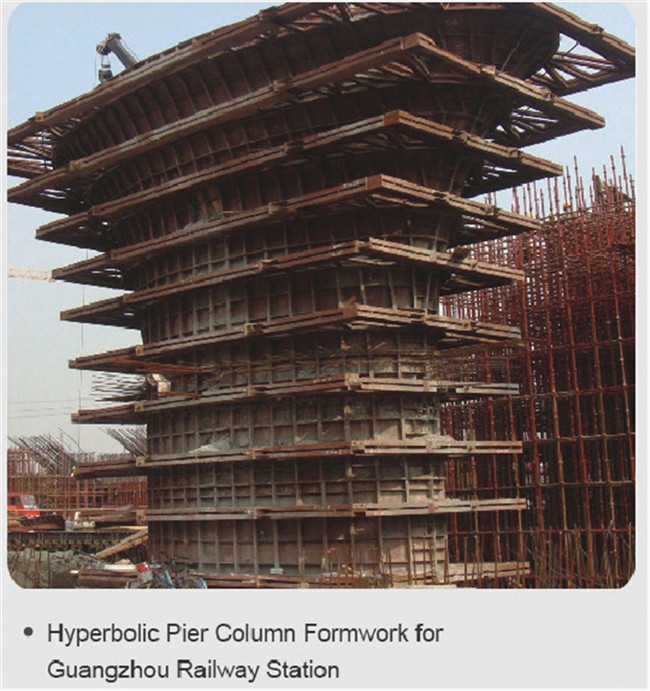

4.Hyperbolic Pier Column Formwork for Guangzhou Railway Sation.

Projects:

- Q: How long will it take to set up the 30 - meter girder erecting machine on the highway

- Erection of 30 m girder bridge machine total length of 56-58 meters

- Q: Now the high-speed rail bridge frame span of the beam

- The bridge erecting machine is a device for placing a prefabricated beam on a prefabricated pier

- Q: Bridge erection of a small box girder of long time

- It depends on the length of your box girder

- Q: What should be done before the erection of the bridge girder

- But what should be done before the erection of the bridge frame? Here for you to explain! 1, bridge erecting machine at the end of the bridge is ready to assemble the beam, should be placed in the bridge at the vertical track, in order to frame beam; 2, the bridge machine cantilever to the next bridge pier; forward process should ensure the stability of truss. 3, the bridge machine in the back of the four hydraulic cylinder at the same time out, so that the bridge machine in the rear of the car to drive, pull the drive car to change the direction of its movement, auxiliary personnel quickly laying the longitudinal track. The hydraulic cylinder is driven by a hydraulic cylinder.

- Q: When does the bridge machine not belong to the gantry crane?

- But it is very different from the general sense of the crane. The requirements of the harsh conditions, and the existence of the beam on the line, or called the longitudinal shift. Bridge machine is divided into the erection of highway bridges, conventional railway bridge, passenger dedicated railway bridge, etc..

- Q: What kind of machinery is the bridge? Is the bridge crane or bridge crane? What is the difference between the three?

- Bridge crane is a bridge crane, bridge crane is also a crane, but not a bridge crane, the harsh conditions of its requirements

- Q: Bridging machine construction method? Common types of bridge machine

- The bridge erecting machine is a device for placing a prefabricated beam on a prefabricated pier

- Q: How many special operators do you need to build a bridge machine? What kind of special operations personnel should be held?

- Other construction workers 10~20 ranging. See the specific operation of the type of equipment.

- Q: Operating rules for bridge erecting machines

- Six, after the erection of the bridge crane must be suspended hanging crane operation, but also can be used to test the concrete beam, bridge erection machine running in place to start the installation work.Seven, bridging machine installation work, we should pay attention to the safety inspection, each installation of a hole must conduct a comprehensive safety inspection, found the problem to stop working and timely processing to continue to work. Do not allow mechanical and electrical failure.Eight, the installation operation is not allowed to overload operation, shall not lift operation.Nine, connecting pin processing materials must be carried out according to the requirements of design drawings, shall not use the low grade instead of processing.

- Q: Purchase of special equipment, the use of units of evidence is the use of special equipment license?Where is the place of use or production?

- Specifically, it is located in the special equipment inspection institute (hereinafter referred to as the quality and Technical Supervision Department)

Send your message to us

Pier Column Formwork and Dam Formwork

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords